Sulphur 403 Nov-Dec 2022

30 November 2022

Acid mist removal

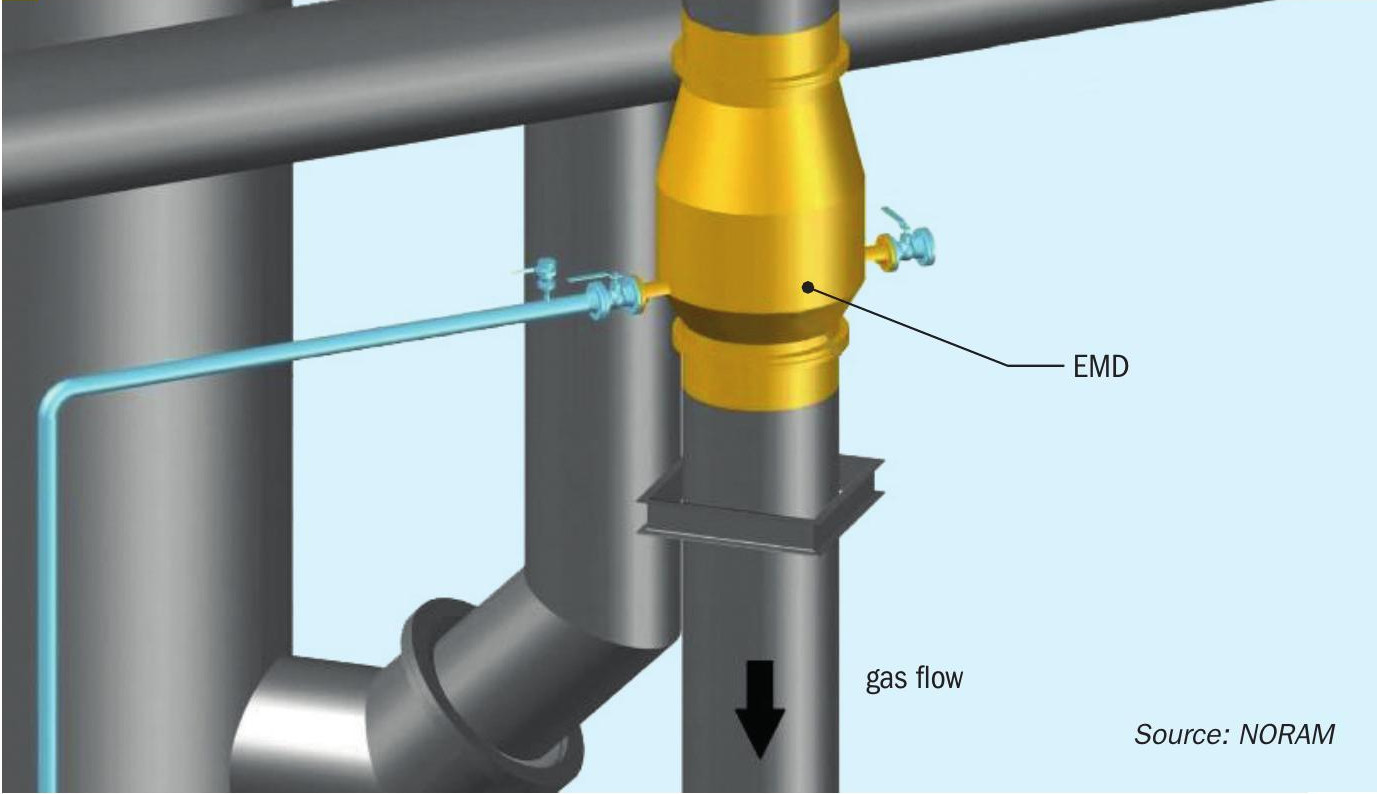

NORAM has recently introduced a patented acid entrainment mitigation device (EMD) to deal with acid mist carryover from sulphuric acid towers.

In sulphuric acid plants acid mist carryover can occur due to a number of factors:

- fine mist carryover from the gas cleaning section into the dry tower;

- excessive acid entrainment from acid tower distributors and/or packing;

- failure of demisters in the dry, interpass and final towers;

- excessive cooling of the gas downstream of acid towers causing increased condensation.

The effects of acid mist carryover can cause the following issues:

- corrosion and damage of equipment such as blowers, gas-to-gas heat exchangers, converters and ducting;

- fouling and increased pressure drop in gas-to-gas heat exchangers;

- catalyst fouling, increased pressure drop and unwanted plant shutdowns to perform catalyst screening (lost production);

- reduced equipment life.

EMD features and performance

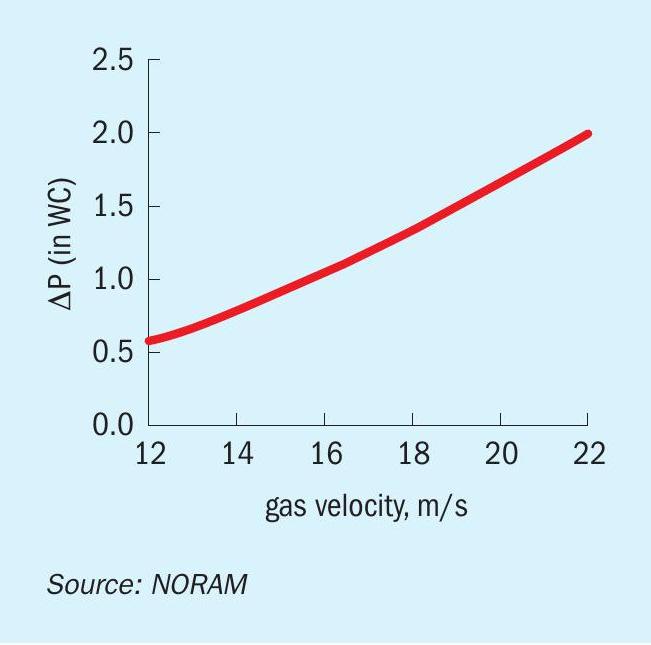

NORAM’s EMD is designed to achieve significant acid entrainment removal while maintaining low gas pressure drop. The equipment pressure drop is between 1and 2-inches WC. The droplet capture efficiency increases for larger particles. The best performance is found for particles above ten microns in diameter.

The EMD features a bundle of swirl tubes that are designed to remove acid droplets from the process gas using a cyclonic principle. The captured sulphuric acid flows along the ducting internal walls and is drained to an existing tank or a drainpot with level indication to act as an early-warning system to alert operators if acid entrainment collection has increased, and therefore identify issues of upstream towers.

The EMD is made of acid resistant alloys and does not require replacement of internals (equipment only to be inspected at plant turnarounds). It does not require a new civil foundation. It will fit in the available space. It can be installed in-line and inside of a process gas duct and does not create an obstruction for process gas.