Fertilizer International 517 Nov-Dec 2023

30 November 2023

LFP batteries – a phosphate industry game-changer?

EMERGING MARKETS

LFP batteries – a phosphate industry game-changer?

Servicing the growth in electric vehicles powered by lithium iron phosphate (LFP) batteries could require the global purified phosphoric acid industry to double in size. Senior CRU consultant Wahome Muya explores the opportunities for unlocking growth in this emerging and fast-moving market.

Introduction

Globally, lithium iron phosphate (LFP) batteries are an increasingly important part of the fast-growing electric vehicle industry. As a result, global LFP demand is forecast to increase more than ten-fold over the next 20 years – spreading well beyond China into the rest of the Asia-Pacific and other regions such as Europe and North America.

The ability of phosphate producers outside of China to tap into this expanding market depends on one crucial factor – whether the LFP industry and its supply chain moves out of East Asia and develops internationally in future. This is by no means certain at present.

The emergence of LFP production outside of China could result in game-changing market growth for purified phosphoric acid (PPA) suppliers globally. Yet such growth is unlikely to materialise if LFP supply chains remain within China, as this would lock out the world’s major phosphate producers from this growing market.

Despite the uncertainty, forecast growth in LFP usage will still require PPA production to double in size globally over the next 20 years, in CRU’s view.

The global shift towards battery electric vehicles

The world is embarking on a major transition away from the internal combustion engine towards battery electric vehicles (BEVs) – driven by rapid technological progress, supportive policy regimes, and shifting consumer attitudes.

Advances in technology have increased the energy density of batteries, extending the travel range of BEVs, while also lowering their purchase and ownership costs to levels comparable with traditional petrol or diesel vehicles. Government subsidies and tax credits to consumers and automakers, alongside legislation, are also encouraging the long-term phase-out of vehicles powered by traditional internal combustion engines. Meanwhile, range anxiety – the fear of BEV owners that their power will run out before they reach the next charging location – continues to slowly decline as battery capacities increase and public charging infrastructure improves.

Combined, these positive factors are driving significant growth in BEV sales globally. These are forecast to reach 18 million units in 2025, up from 2.3 million in 2020 – an eight-fold increase over five years. By 2045, BEV annual sales of 65 million are expected, accounting for more than two-thirds of total light-duty vehicle sales globally.

The enormous growth in global BEV sales anticipated over the next 20 years will be coupled to the rising popularity of both LFP and – in the longer term – lithium manganese iron phosphate (LMFP) batteries. Indeed, for BEVs, the global market share of LFP/LMFP batteries is expected to increase from 15 percent in 2020 to 33 percent in 2025 and then to 37 percent in 2035.

The growing use of LFP/LMFP batteries in BEVs is due to a wide range of factors (Figure 1). These include their:

- Lower cost relative to nickel-rich batteries

- Greater longevity

- Superior level of safety.

In addition, the main downside to LFP batteries historically – their lower energy density relative to nickel manganese cobalt oxide (NMC) batteries – has been largely offset by technological improvements. Nonetheless, nickel-rich NMC batteries do still retain a slight energy density advantage, as well as offering superior performance at low temperatures. The higher value of their raw material constituents also makes the recycling of NMC batteries more economically viable.

Outside the BEV market, the greater usage of LFP batteries in energy storage systems is also on the rise. Valuable characteristics such as low-cost, durability, and thermal stability make LFP batteries particularly well-suited for this end-use.

Rocketing global demand

The LFP market is forecast to grow more than ten-fold over the next 20 years – with demand accelerating and spreading well beyond China’s borders. At present, though, China completely dominates the LFP market, being responsible for more than 90 percent of world demand (200 GWh in 2022).

The current popularity of LFP batteries with Chinese auto manufacturers can be explained by two factors:

- Firstly, their lower cost relative to NMC batteries.

- Secondly, the preferences and travel habits of Chinese EV owners. These are geared towards shorter urban journeys in small/medium-sized vehicles – in contrast to the popularity of larger SUVs in the US and other markets.

Technical improvements in battery design, electric motors, power electronics, and vehicle lightweighting are helping to overcome the traditional range disadvantage associated with LFP batteries and help broaden their appeal outside of China.

Recent innovations in battery packs pioneered by Chinese manufacturers – such as ‘cell-to-pack’ battery configurations with large-format cells – have also delivered further cost savings and energy density improvements. This has added to LFP battery uptake in China, while also adding to their attractiveness to automakers in other regions.

All of these improvements, coming on top of traditional advantages such as low-cost, safety, and durability, are expected to drive greater LFP battery adoption in Europe, North America, and other parts of the Asia-Pacific.

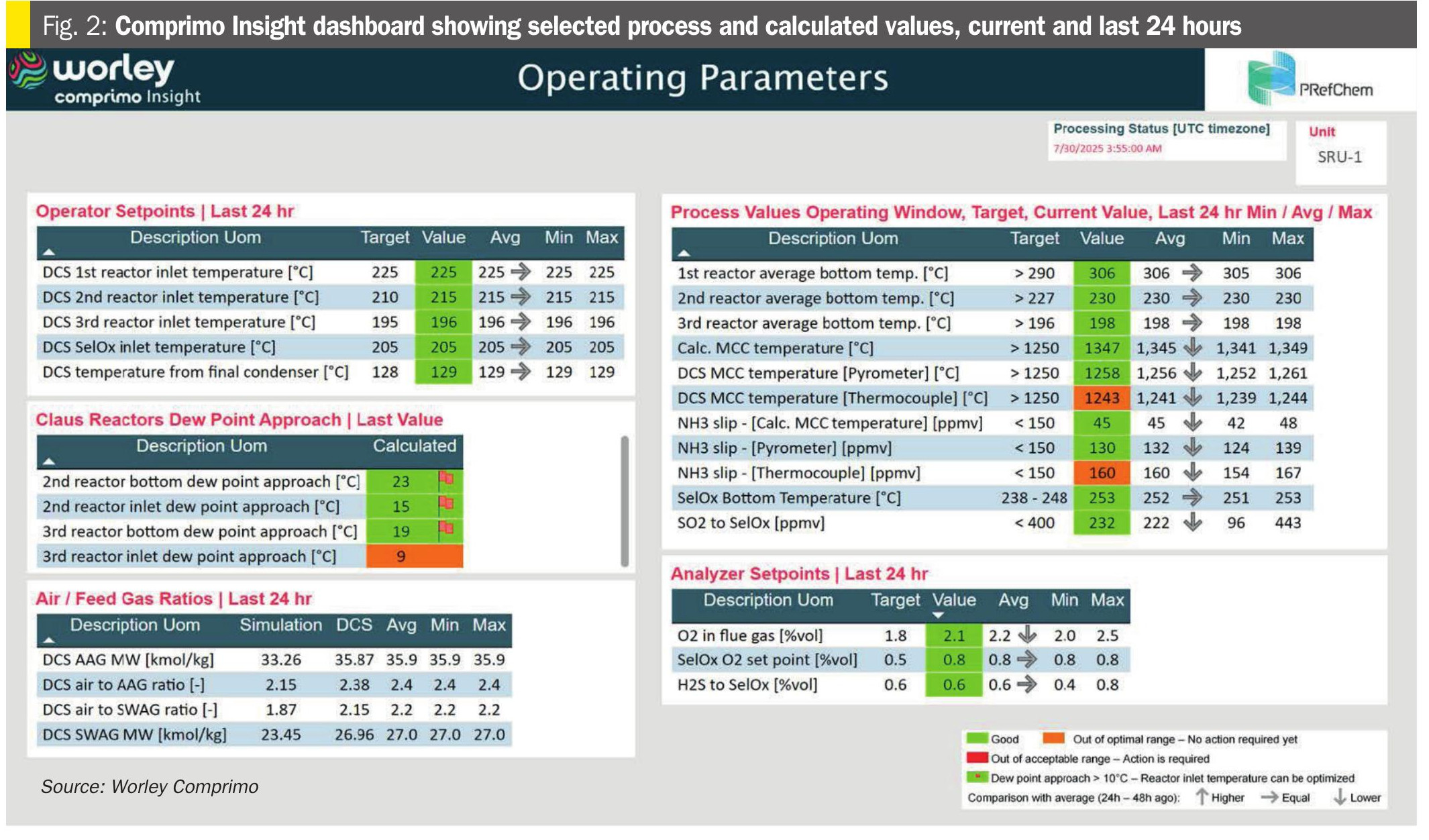

Indeed, CRU is forecasting a more than ten-fold increase in global LFP demand over the next 20 years or so, with around 60 percent of this demand expected to be based outside of China at the end of this period (Figure 2). In CRU’s, China will cease to be the sole dominant player over the medium- and long-term, as the LFP market expands internationally and becomes more relevant to automakers, battery producers, and raw material suppliers – including the phosphate industry – in the rest of the world.

International expansion prospects

In the LFP battery production process (Figure 3), purified phosphoric acid (PPA) is used as a starting material to generate iron phosphate, either directly or via a monoammonium phosphate (MAP) intermediate, which is then combined with lithium carbonate to manufacture LFP cathodes. These are incorporated within LFP batteries alongside other key components, namely the anode, electrolyte and separator.

Currently, virtually all the world’s manufacturing capacity for LFP cathodes is based in China. The iron phosphate used to produce these cathodes is also sourced domestically – China being self-sufficient in phosphate and accessing iron ore imports for its steel industry.

China will continue to domestically supply the raw materials and precursors used in LFP production, such as PPA and iron phosphate, as long as its in-country manufacture of LFP cathodes dominates the global market. This situation, if it were to continue, would essentially lock-out phosphate producers located outside of China from the LFP industry and prevent them from enjoying the sales growth and premiums associated with this emerging market.

Therefore, the key question for international phosphate producers is whether LFP cathode manufacture – and the PPA and iron phosphate supply underpinning this – will expand outside of China and proliferate in other regions over the long-term to reflect the pattern of LFP demand.

Recent LFP battery project announcements are now helping to answer this question. Many of these new LFP battery cell plants are due to be built in North America and Europe over the next 5-10 years, with the total planned manufacturing capacity in these regions surpassing 150 GWh and 200 GWh, respectively.

However, it is rare for these battery projects to include captive/integrated upstream production capacity for LFP cathodes. Non-integrated, standalone LFP cathode capacity in these regions also falls far short of the necessary supply requirements of these battery cell projects. The upshot is that planned regional LFP cathode capacity is only sufficient for 13 percent and 7 percent, respectively, of announced battery cell capacity in North America and Europe, according to CRU estimates, resulting in respective LFP cathode manufacturing deficits of 87 percent and 93 percent.

This suggests that, unless we start to see many more LFP cathode projects announced in regions outside of China over the coming months and years, the cathode requirements of North America and Europe will be largely met through imports, even if both regions succeed in building up domestic LFP battery cell capacity. In this scenario, the phosphate raw materials required for LFP battery cathodes would still be sourced and consumed within China.

The extent to which new legislation can incentivise local production of LFP cathodes in North America and Europe remains to be seen. The 2022 US Inflation Reduction Act (IRA) does promote the domestic production of electric vehicle batteries and battery components. Yet, while this has played some role in incentivising new LFP battery cell projects, we have yet to see the same effect for cathode projects.

A similar EU policy – the Critical Raw Materials Act – is also being planned. But this proposed legislation is at an earlier stage than its US equivalent, making its effectiveness in encouraging domestic LFP cathode projects even less well-understood.

Purified phosphoric acid capacity to double?

Nonetheless, while the effects of LFP demand growth on regional demand for purified phosphoric acid (PPA) remain uncertain, it is likely that the global industry will need to double in size over the next 20 years, in CRU’s view.

Our long-term forecasts for PPA demand in North America and Europe are based on three scenarios (Figure 4), these varying according to where LFP cathode and iron phosphate production is located:

- In Scenario 1, China continues to dominate both global LFP cathode and iron phosphate production, despite growing LFP demand in the rest of the world. This outcome would result in minimal uplift to PPA demand in North America and Europe – totalling just +4 percent in 2045. In this scenario, these two regions would largely import LFP cathodes from China to supply their battery cell plants.

- In Scenario 2, both regions establish enough domestic production capacity for LFP cathodes and iron phosphate to fully eliminate their import reliance on China. This outcome would deliver a considerable upside to the PPA industries in North America and Europe. PPA demand would be 60 percent higher in North America in 2045, for example, while the European PPA market would nearly double (+90 percent).

- In Scenario 3, in-region production of LFP cathode and iron phosphate is combined with an upside LFP demand forecast. This outcome would deliver incremental increases in PPA demand of +80 percent in North America and +130 percent in Europe – resulting in game-changing market growth for domestic PPA suppliers and exporters to both these markets.

CRU has also estimated Chinese PPA demand out to 2045 under three different scenarios. In Scenario 1, the country, by continuing to be the world’s exclusive supplier of LFP cathodes, would see its domestic PPA market size more than double (+110 percent). Furthermore, when coupled to an upside LFP forecast (Scenario 3), China’s PPA demand levels grow hugely (+150 percent) above its non-LFP requirements. However, the expected rise in PPA demand falls back to +50 percent in our base case forecast. In this situation, China is no longer the world’s exclusive LFP cathode supplier and instead only produces enough to supply its domestic market needs (Scenario 2).

Summing up

At the global level – regardless of whether China continues to dominate LFP cathode and iron phosphate production – CRU’s forecasts show overall PPA demand far outstripping current world capacity in the long term, driven primarily by LFP market growth. In our base case, global PPA capacity would need to nearly double in size by 2045 (+95 percent) to meet LFP demand growth, while our upside forecast requires PPA capacity to grow by as much as 120 percent (Figure 5).

The magnitude of global LFP demand growth, combined with uncertainty about where this will be distributed geographically, presents phosphate industry players with a number of strategic questions – these being of interest to incumbent and prospective phosphate producers, raw material suppliers, cathode and battery manufacturers, investors, and policymakers.

Fortunately, the team at CRU Consulting is well placed to answer these wide-ranging questions, including:

- The likely effectiveness of legislation in the West to encourage localised battery supply chains

- The potential price premiums that phosphate producers supplying the LFP sector might enjoy

- The potential for first-mover advantage for phosphate producers entering the LFP industry outside of China.

CRU Phosphates 2024

The LFP battery market will be a hot button topic at the forthcoming 16th CRU Phosphates Conference being held in Warsaw, Poland, 26-28 February 2024 (p43). Register at: events.crugroup.com/phosphates/register