Nitrogen+Syngas 386 Nov-Dec 2023

30 November 2023

Pioneering green ammonia – start small, think big

GREEN AMMONIA

Pioneering green ammonia – start small, think big

Distributed and carbon-free ammonia production with Stami Green Ammonia technology offers a highly competitive alternative to conventional grey processes, paving the way for scaling up and sustaining local communities with renewable energy sources.

As the world shifts toward sustainable solutions, it has become clear that traditional ammonia production methods, which depend on non-renewable resources and contribute to global GHG emissions, must be redefined. However, with approximately half of the global population relying on artificial fertilizers for their food supply, the production of ammonia and its derivatives must keep growing. Additionally, ammonia is expected to play an important role as an energy carrier in the transition to clean energy. To meet sustainability objectives while addressing rising demand, ammonia production must increase, but it’s imperative that it’s sourced from renewable sources.

More ammonia, less carbon

The Haber Bosch process, developed in the early 1900s, revolutionised high-pressure ammonia synthesis. It directly combines nitrogen from the air with hydrogen under high pressure and moderately high temperature. The invention resulted in the wide availability of ammonia-based fertilizers that rapidly increased agricultural yields in a short time span.

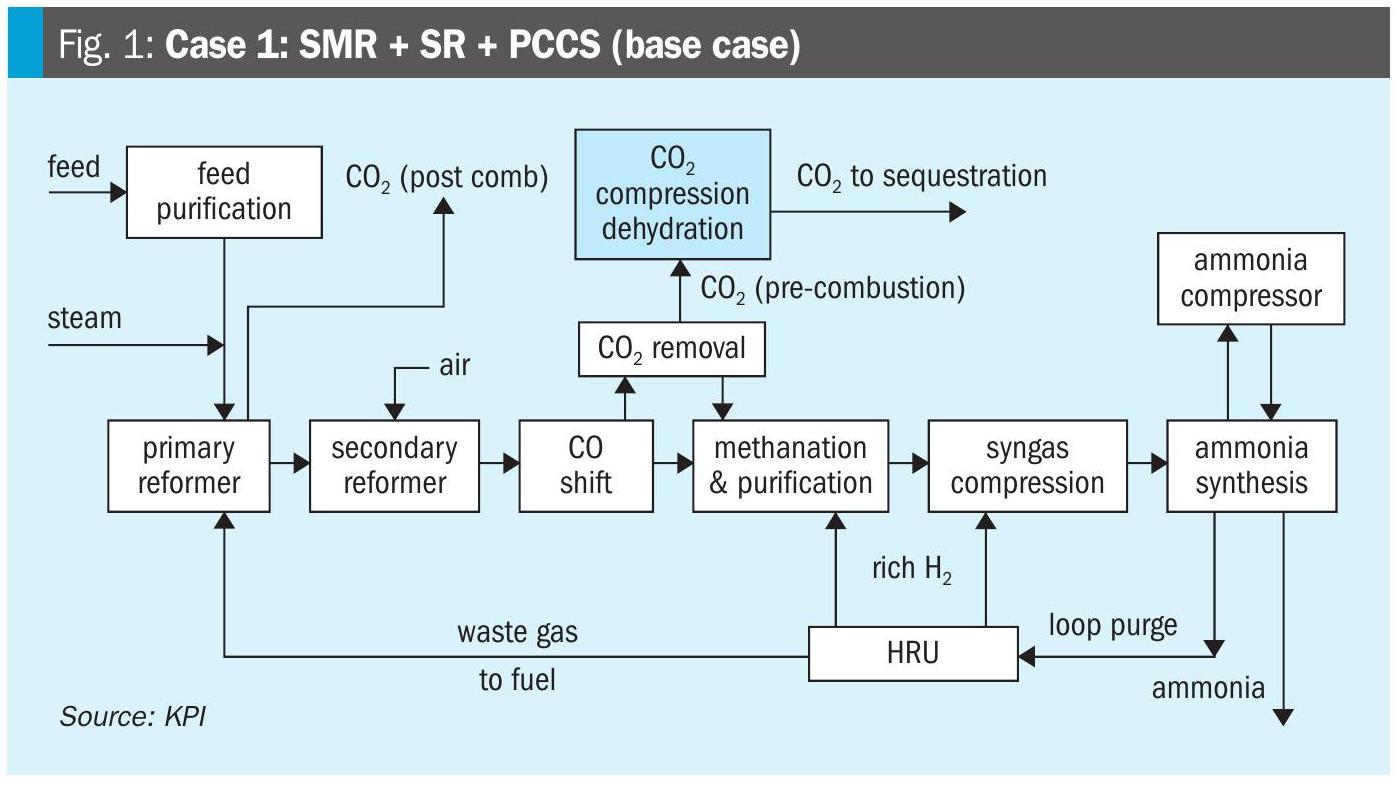

Today, most ammonia facilities are using hydrogen from steam reforming of natural gas or coal gasification. While hydrogen continues further into the synthesis, carbon dioxide, having no other role, is mainly released into the atmosphere. Fortunately, the Haber Bosch process can use hydrogen from any source. When renewable electricity with an electrolyser is utilised to produce hydrogen, combined with the atmospheric nitrogen down the line (see Fig. 1), the resulting ammonia is referred to as “green.”

The economy of smaller scale

Historically, the process industry aimed to increase production and capitalise on economies of scale. As we transition to green energy to power and sustain the world, this approach remains relevant. However, the limited availability of renewable electricity and production capacities of electrolysers – essential for transitioning to green hydrogen and subsequently to green ammonia – are slowing the deployment of large-scale non-fossil projects. Given today’s challenges and opportunities, starting with smaller-scale, modular, and scalable green ammonia production can be a smart step toward a carbon-free journey.

Stamicarbon, the nitrogen licensor of the MAIRE Group, recognises the urgency to pursue sustainable, carbon-neutral ammonia production technologies, as well as the new opportunities that have arisen. To address the sustainability challenge effectively, Stamicarbon developed its high-pressure green ammonia technology with a capacity of up to 500 t/d. By enabling ammonia production from renewable energy sources, Stami Green Ammonia offers a path to a carbon-free future, enabling a more environmentally friendly approach to producing nitrogen-based fertilizers or converting renewable energy to a valuable commodity with multiple ways of further monetisation.

Features of Stami Green Ammonia technology

Central to Stamicarbon’s technology is a high-pressure ammonia synthesis loop tailored to provide optimal efficiency in smaller to medium-sized plants using renewable energy as a feedstock. A major benefit of this high pressure is that it enables ammonia to condense in a single stage using cooling water. This efficiency reduces the need for multiple pieces of equipment, resulting in capex savings of around 25-30%. This is a notable advantage of smaller applications. Additionally, the high pressure means that the synthesis requires only a minimal reactor size and smaller catalyst volume. An illustrative process flow diagram can be found in Fig. 2.

The chemical process to produce ammonia is most efficient under low temperatures and high pressures due to the exothermicity of the reaction. Stami Green Ammonia technology operates at a higher synthesis loop pressure of 300 bar, distinguishing it from other technologies that typically operate between 80-150 bar.

The Stami Green Ammonia process capitalises on the proven designs from established natural gas-based technologies and its modular approach makes it suitable for decentralised, small-scale production. The plant, due to its scale and design, can efficiently handle the sporadic nature of renewable energy sources. Customised plant capacities ranging from 50 to 500 t/d ammonia are possible. Due to its streamlined design, a 500 t/d ammonia plant covers an area of roughly 50 x 45 metres (see Fig. 3). Depending on the project site, available space, and various local factors, either a stick-built or a fully modular design may be employed.

As seen from multiple studies developed by Stamicarbon for its customers worldwide, local green ammonia production can be feasible in many regions. The high availability of solar energy resources enables the production of green hydrogen and ammonia in Africa, the Middle East, South America, and Oceania. Furthermore, other regions have access to various renewable energy sources, like wind and hydropower, enabling the local production of sustainable fertilizers and driving the energy transition in other industries. Establishing local, distributed production facilities offers more than just high-added-value products. Local fertilizer production would have an impact on the affordability and availability of fertilizers for farmers. Local communities would benefit from developmental projects undertaken as part of the corporate social responsibility of the fertilizer plants. Plant construction would create employment and educational opportunities and boost the development of infrastructure.

Case: Carbon-free fertilizer for America’s Corn Belt

One of the industry’s pioneers, the Meadowlark project, announced in May 2023, promises to bring substantial benefits to the agricultural sector in Gothenburg, Nebraska. This innovative renewable-energy-based liquid fertilizer plant will be based on the Stami Green Ammonia technology and is expected to start up in 2026. Stamicarbon will develop a basic engineering design package for a 450 t/d green ammonia plant that will be used to produce nitrogen-based fertilizers (Fig. 4). Leveraging locally produced renewable energy, the facility is projected to produce impressive outputs: 365,000 t of urea ammonium nitrate (UAN), 146,000 t of ammonium thiosulphate (ATS), and 20 million gallons of diesel exhaust fluid (DEF) annually. Strategically located, Project Meadowlark aims to cater to an agricultural area spanning approximately 150 miles around Gothenburg.

Fossil-fuelled ammonia plants are traditionally located at places rich in available natural gas or coal. This leads to an uneven distribution of fertilizer production worldwide and adds to transportation costs and emissions. To address these challenges and promote sustainability, there is a growing need for alternative production methods that utilise renewable resources and decrease the overall carbon footprint of ammonia production. Green ammonia production not only has zero CO2 emissions but is also less tied to a specific location, provided sufficient renewable energy is available in different locations across the world. This gives many countries the opportunity to become self-sufficient in fertilizer production, thereby reducing issues related to supply chain disruptions and unexpected price fluctuations.