Fertilizer International 525 Mar-Apr 2025

18 March 2025

CRU Phosphates+Potash welcomes you to Orlando!

CONFERENCE PREVIEW

CRU Phosphates+Potash welcomes you to Orlando!

CRU will convene the 2025 Phosphates+Potash Expoconference in Orlando, Florida, at the Hyatt Regency Grand Cypress Resort, 31 March – 2 April.

CRU’s 2025 Phosphates Conference – now in its 17th year – is returning to Orlando, Florida, this year. The 2024 event in Warsaw was one of the most successful to date – attracting more than 370 delegates from over 150 companies and 40 countries (Fertilizer International 519, p4).

Building on that success, this year’s event has even more to offer. That’s because it will also champion the potash industry – as its new name CRU Phosphates+Potash Expoconference makes clear. Leading international producers, traders and engineering, technology and equipment providers are all expected to attend.

Bringing together two sister segments

So, why potash? Unbelievably, for a sector that produces close to 70 million tonnes of potassium chloride annually, there’s never actually been a regular yearly event for the global potash industry.

Potash and phosphate are both mined commodities with common extractive and process technologies. Crushing, grinding, screening, pumping, froth flotation, liquid-solid separation, dewatering, drying, evaporation and crystallisation are common to both industries.

Because of that, phosphates people are, more often than not, also potash people. That applies to engineering companies, equipment manufacturers, reagent suppliers, technology providers and crop nutrient producers.

That’s why it makes perfect sense to bring these two sister industries together in a single event. The massive investments currently underway in highly efficient potash mining and processing technology – and the pursuit of electrification, automation and digitalisation – also need highlighting. In short, the potash industry deserves an annual gathering where it can network, hear the latest market intelligence and share new knowledge.

Consequently, starting in Orlando this year, CRU is building a new global community that jointly celebrates the phosphate and potash industries. We invite you to join us there – as well as spread the word that potash has a new home.

A return to Florida

Orlando’s North American location makes it an ideal place for the global phosphates and potash industries to meet up, network and access crucial market intelligence and technical updates. Especially as the region is home to Florida and Saskatchewan – two global centres of phosphates and potash excellence (see page 48).

This timely spring conference will inform and spur discussions on key issues such as sustainability, trade, supply chain challenges and technical advances – all of which are occurring against a tumultuous market backdrop of geopolitical upheaval, volatile fertilizer prices and supply constraints.

What to expect – the 2025 agenda

Uniquely, CRU Phosphates+Potash combines a commercial agenda with a technical agenda in one single event. This enables the conference to cover the entire value chain of the phosphate and potash industries from both an operational and market perspective.

This year’s conference features a typically strong commercial programme. This will offer up key insights and in-depth market information on the supply, demand and pricing of P&K raw materials and finished products. Programme highlights include:

• A global perspective on potash and phosphate

• Phosphate and potash prices, demand and supply outlooks

• Outlook for the North American phosphate market

• Applying phosphate when grower profitability is challenged

• The future of potash in a changing world

• Fifty years of phosphorus research at IFDC

• The Indian fertilizer market

• Phosphate project prospects

• The yellow phosphorus market

• Collaborative innovation

• LFP batteries

• Feed phosphates update

• Phosphate rock supply.

The event also offers a separate but equally strong technical programme (see selected abstracts p39). This is designed to cater to the needs of production personnel throughout the phosphate and potash value chains. Indeed, the 2025 conference is set to break records with an impressive lineup of more than 30 technical innovation presentations and six dynamic technical showcases.

These will offer a deep dive into the intricacies of new technology, groundbreaking processes, novel materials and state-of-the-art equipment. Delegates will discover how these innovations can elevate production efficiency, ensure environmental compliance, and increase operating capacities and plant output.

Register today for your place at CRU Phosphates+Potash 2025 in Orlando. For more information visit: events.crugroup.com/phosphates/home

Technical programme highlights

A selection of Phosphates+Potash 2025 abstracts from the conference’s technical programme.

Improving 4-rotor continuous mining performance

The Mosaic Company

A fleet of 4-Rotor continuous boring machines are used for underground mining at Mosaic’s Esterhazy K3 Potash mine. Rooms of 6,000 feet in length are cut in three passes, with the first pass being the most challenging. Mosaic uses a patented Automated Hardware Installer (AHI) for its entire mining fleet at Esterhazy K3. This follows behind the mining machine, automatically drilling post holes and installing hardware posts and idlers. Two key programmes have now been implemented at K3 to improve first pass cutting performance and AHI uptime: Routine Equipment Care (REC) of the first pass mining process; and Reliability Centered Maintenance 2 (RCM2) analysis of the AHI. This presentation provides an overview of the implementation of REC and RCM2, summarises the results and outlines the lessons learned.

Sustainable bio-based coatings

ArrMaz-Arkema

This presentation evaluates the performance of an alternative, bio-based dust control and anti-caking coating for potash and monoammonium phosphate (MAP). Both these fertilizers are prone to dust generation and caking during storage and transport. Results show that the bio-based coating delivered equal or superior dust control and anti-caking performance compared to conventional oil-based coatings, with significant environmental advantages. Other studies have revealed that fertilizers coated with this bio-based material also offer agronomic benefits by improving crop growth.

Coarse phosphate flotation at the Elandsfontein mine

Eriez

HydroFloat® Coarse Particle Flotation (CPF) has been implemented at Kropz’s Elandsfontein phosphate mine since its recommissioning in December 2021. CPF reduces turbulence and particle detachment by combining a fluidised bed with the absence of a froth zone. It also increases the flotation rate of both coarse and partially liberated particles, compared to conventional flotation. The redesigned Crago flotation circuit at Elandsfontein now consists of fine (+25-212 micron) and coarse (+212-425 micron) flotation circuits using Eriez CavTube® column flotation and Hydro-Float® CPF technologies, respectively, together with a conventional reverse coarse flotation circuit cleaning stage. The adoption of a split-feed flotation circuit has enabled the recovery of coarsely liberated apatite particles while reducing grinding requirements.

Fine screening in potash

Derrick Corporation

The use of closed-circuit screening systems in potash processing enhances product recovery and purity. Benefits include improved product quality, reduced operational costs and increased throughput. This presentation explores how potash particles can be efficiently separated, based purely on size, by integrating vibrating screens within closed circuits. Screening systems maximize the recovery of valuable minerals – while minimising waste and ultrafine generation – by recycling oversized material back into the crushing or grinding process. The effectiveness of screening is influenced by operational parameters such as screen mesh size, feed rate and percent solids.

Reducing fines in potash processing

Hatch

Minimising fines generation in potash operations is critical for improving recovery and overall economic viability. Fines account for a significant portion of product losses and can consume additional flotation reagents. They also adversely impact flotation performance and require more energy for dewatering and drying. The fines produced during comminution, attrition scrubbing and handling (-10 µm particles) are of particular concern – as these are below the minimum size that can be recovered economically.

Innovative leaching technologies

Prayon Technologies

Phosphoric acid producers are currently facing two significant challenges. First, the rising cost of high-grade phosphate rock is putting increasing financial pressure on the industry. Second, regulatory requirements for lower cadmium, arsenic and other contaminants are also becoming stricter. Last year, Prayon Technologies introduced a targeted leaching process for removing magnesium from phosphate rock. Building on that success, Prayon has since broadened its leaching capabilities – and now offers additional solutions for removing total organic carbon (TOC), cadmium and other impurities. The ability to provide phosphoric acid producers with a custom-made leaching process is economically beneficial, as it avoids the need to switch from lower-quality phosphate rock to more expensive high-grade sources.

Adapting JPMC’s phosphoric acid plant to low-grade rock

Prayon Technologies, De Smet Agro

The performance of the Jordan Phosphate Mines Company (JPMC) phosphoric acid plant in Aqaba has been declining due to the decreasing quality and increasing moisture content of the phosphate ore. These factors, by reducing plant capacity and filtration performance, have made achieving target merchant-grade acid (MGA) concentration increasingly difficult. To address these challenges, Prayon Technologies and De Smet Agro jointly conducted a comprehensive revamping study aimed at restoring the plant’s operational performance to its historical peak in the mid-1990s, a time when phosphate rock quality was higher. Several modifications were proposed that – while preserving the plant’s current attack-digestion section – are capable of delivering the necessary process improvements.

Halite removal from potash using X-ray-transmission sorting

TOMRA Sorting

TOMRA Sorting and K+S have jointly developed a sensor for the separation of halite (NaCl) from sylvinite (KCl) in potash ore mining. This resulted in the design, construction and commissioning of a pilot X-ray-transmission (XRT) sorting plant in the Zielitz underground potash mine in Germany in 2022. This plant enables more than half of the mined material to be sorted in situ and remain underground, instead of being hoisted to the surface and then deposited on top of already huge waste stockpiles. Further investigations are currently underway at the mine to optimise separation performance, increase throughput and implement XRT technology at full scale.

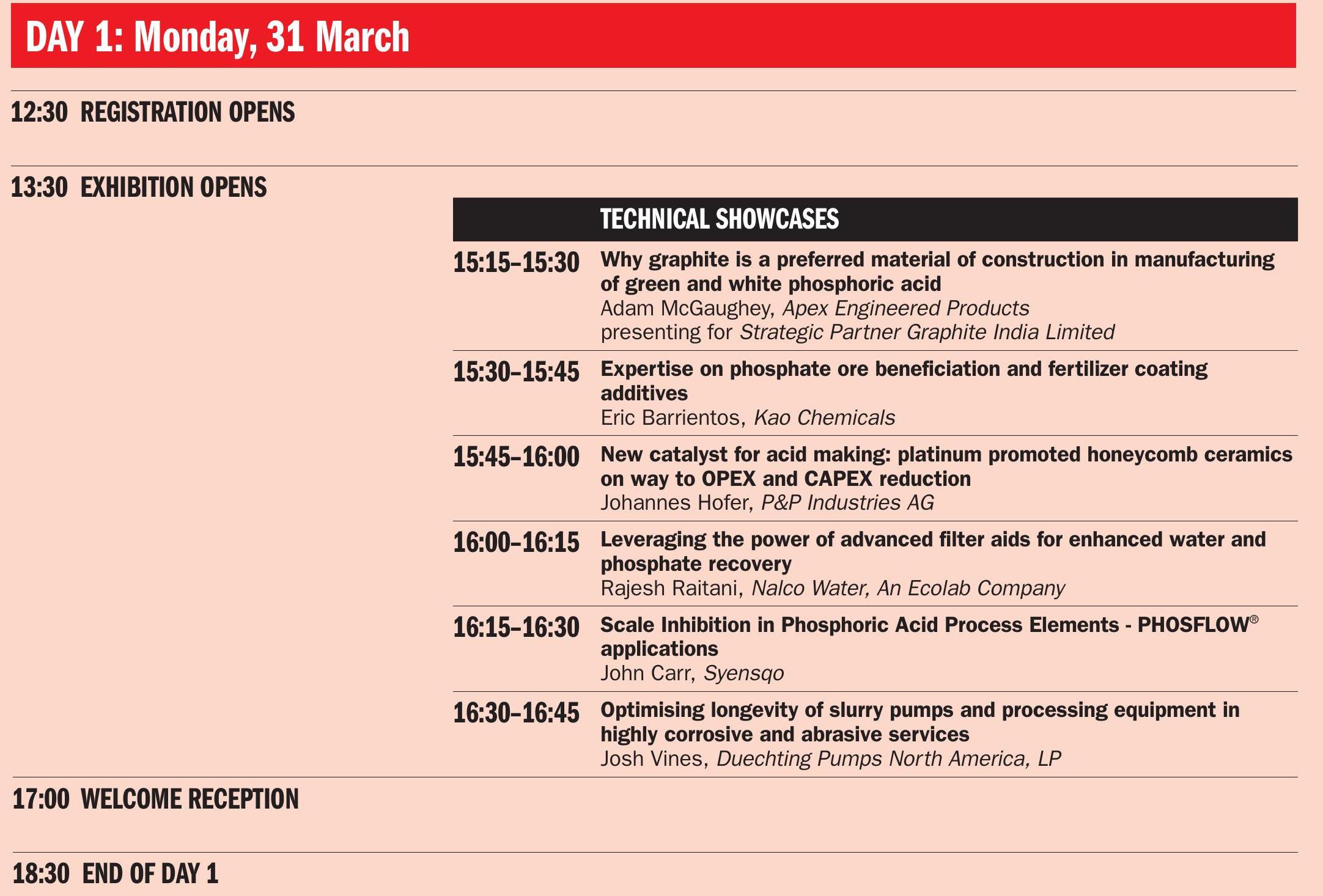

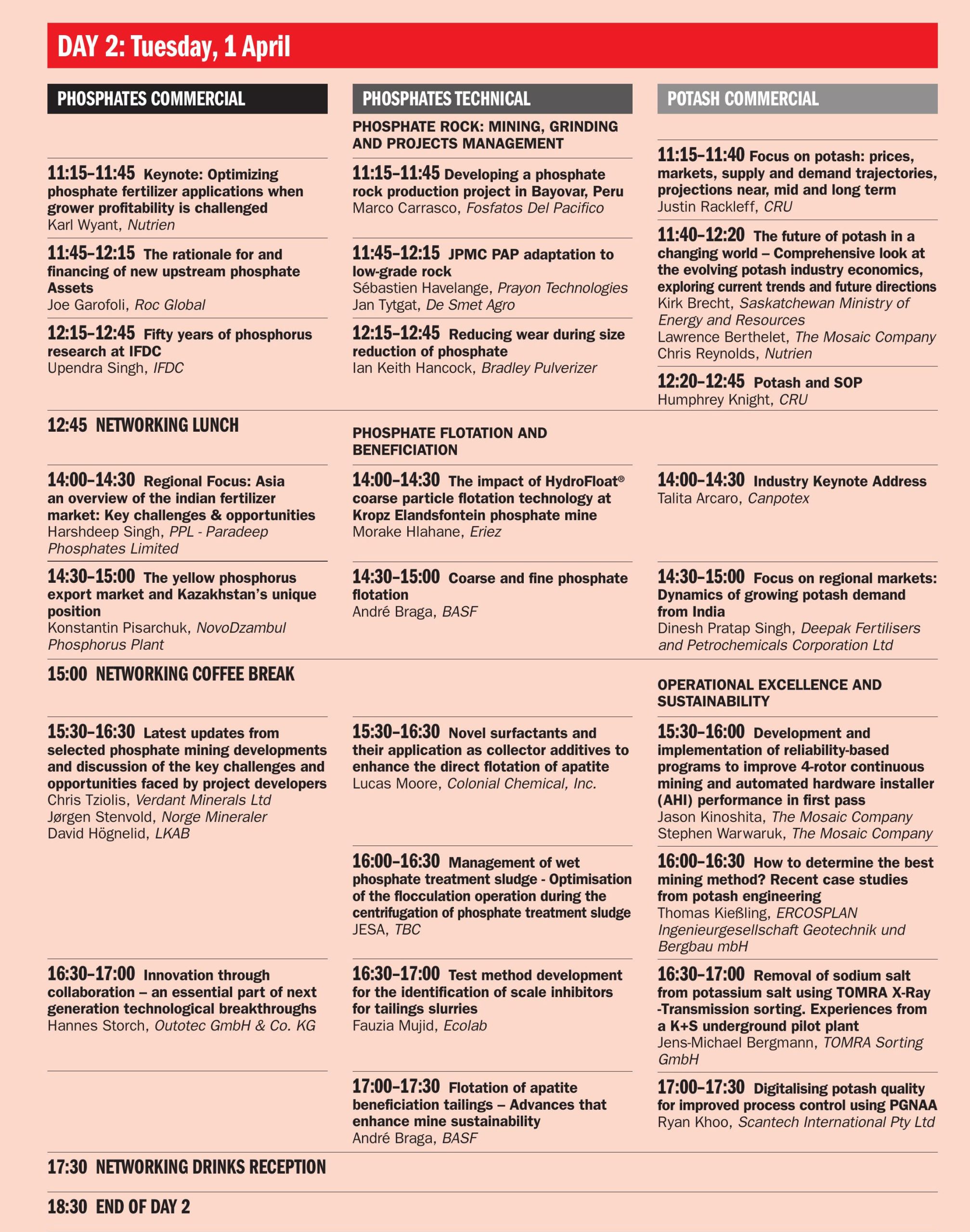

Conference agenda

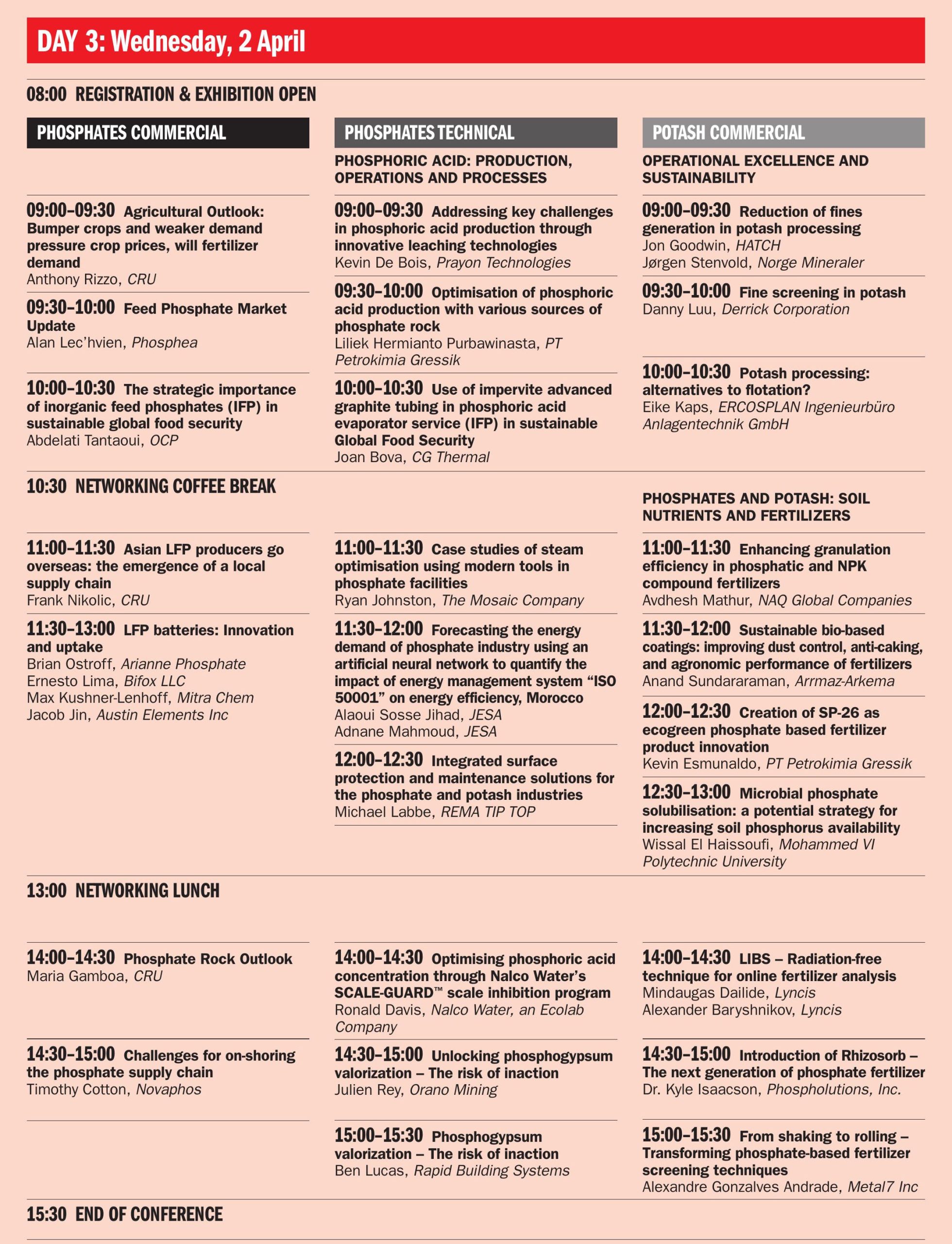

Exhibition plan

Exhibitor list

1 Scantech International Pty Ltd

2 JAS Global Industries

3 Apex Engineered Products

4 Arkema

5 P & P industries

6 BSK Global

13 Eriez

14 De Smet Agro

15 DUECHTING PUMPS

16 Rema Tip Top

17 Mersen

18 GEA

19 Glatt Ingenieurtechnik GmbH

20 Teknokon Makina

21 Kimre/Socrematic

22 ANDRITZ

23 Prayon

24 Keyon Process

25 KAO

26 CiDRA Minerals Processing Inc.

27 HAVER NIAGARA GmbH

28 TOMRA Sorting GmbH

29 OCP

30 Steuler-KCH

31 OBI Linings

32 PegasusTSI Inc

33 SULZER

34 Blair Rubber Company

35 FEECO International, Inc

36 Gambarotta Gschwendt Srl

37 Nalco Water | An Ecolab Company

38 CG Thermal

39 NAQ Global

40 Begg Cousland Envirotec

41 Syensqo

42 Endura Paint

43 Forbon Technology

44 Schurco Slurry

45 NEELAM AQUA & SPECIALITY CHEM

46 GKD-USA Inc.

47 Bradley Pulverizer

48 Polycorp

49 Derrick Corporation

50 Hatch

51 Weir

52 Lyncis

53 JESA

54 Worley Chemetics

Exhibitor profiles

Andritz Separation

Stand 22

ANDRITZ Separation provides mechanical and thermal solid/ liquid separation technologies, together with comprehensive services and solutions for automation and digitalization. The company’s customised, innovative solutions ensure optimal performance and efficiency. The well-proven ANDRITZ Tilting Pan Filters, combined with UCEGO® vacuum table filter technology, are perfect for phosphoric acid filtration. These filters deliver unsurpassed performance when complemented by ANDRITZ’s Metris addIQ ACE technology.

Contact: Kristina Wertenbruch

De Smet AGRO

Stand 14

De Smet AGRO, a subsidiary of De Smet Engineers & Contractors, located on the outskirts of Brussels, provides engineering and project management services to the fertilizer industry. Our focus is on technologies for phosphoric acid, MCP-DCP, ammonium nitrate and granulation. We support clients worldwide – from technical audits through to full EPCM implementation.

Contact: Jan Tytgat

GEA

Stand 18

GEA is one of the world’s largest suppliers of process technology and components for sophisticated production processes. We offer a wide range of plant technologies, including evaporators, crystallizers, centrifugal separators, spray dryers and fluid beds for agglomeration/granulation. These are tailored to fit the requirements of fertilizer and phosphates applications.

Contact: Chris Walton

Haver & Boecker Niagara

Stand 27

Haver & Boecker Niagara offers sustainable and efficient equipment and solutions for the processing, handling, packing and storage of organic, mineral and chemical fertilizers. Its signature screening and pelletizing technologies are complemented by a complete portfolio of products and services for the fertilizer industry, from the extraction and processing of raw minerals through to packaging and loading for delivery at facilities worldwide.

Contact: Julie Andras

JAS Global Industries

Stand 2

JAS Global Industries is a leading global manufacturer and partner to the fertilizer industry. Our innovative, sustainable and cost-effective chemical additives include anti-caking, dust control and colouring agents for all types of granular fertilizers. In addition, JAS Global Industries offers an extensive portfolio of innovative process solutions for the complete value chain – from ore processing to coated fertilizer.

Contact: Khaled Matalka

KAO Chemicals

Stand 25

KAO Chemicals has supplied the fertilizer industry for more than 45 years with anti-caking and dust control agents for MAP, DAP, TSP, NPK blends, AN, CAN, urea, AS, etc. The company also supplies agents for LDAN (external and internal), corrosion inhibitors for liquid fertilizers and flotation collectors. Its well-known brand names include SK FERT®, URESOFT®, DANOX® FL and COLMIN®.

Contact: Eric Barrientos

NAQ Global

Stand 39

Driven by innovative green technology, NAQ GLOBAL is a world-leader in environmentally sustainable and cost-effective products for mining, fertilizer processes and fertilizer quality improvement. Our product lines include: froth flotation agents, flocculants, surfactants, defoamers, descalants & anti-scalants, granulation additives, anti-caking coating agents, dust control coating agents, organic coating agents, micronutrient binders, colouring agents and nitrogen stabilisers. NAQ GLOBAL supplies these specialised products to over 200 fertilizer production and blending units worldwide.

Contact: Fernanda Dias

Prayon Technologies

Stand 23

Headquartered in Belgium, the Prayon Group is a worldwide leader in phosphate chemistry and, with more than 130 years experience, offers the best solutions for phosphate production. The Group specialises in phosphate chemicals and operates production sites in Belgium, France, Switzerland and the United States. Prayon manufactures and distributes a wide range of purified phosphoric acids, phosphate salts and fluorine products geared towards the food and fertilizer sectors, as well as for many different industrial applications. Prayon Technologies (PRT) sells the know-how and techniques developed by our Group, and also supplies consultancy and support services. Profile develops and sells equipment solutions (filtration, mixing, and product recovery) that enable processes to function at optimum efficiency.

Contact: Corine Petry

Sulzer

Stand 33

With 190 years of experience, Sulzer offers its customers best-in-class products and services in pumping, agitation and mixing solutions. These add value, especially to processes involving corrosive and abrasive media. Sulzer offers a complete range of process and slurry pumps, axial flow pumps, heavy-duty agitators and liquid ring vacuum pumps tailor-made for the phosphates and potash industries. These cover applications ranging from mineral beneficiation of phosphate and potash ores to the manufacture of fertilizers. Our advanced design and materials, plus a wide range of shaft seals and sealing systems, ensure a reliable process and maintenance-free operation. Our Sense wireless condition monitoring solution, meanwhile, supports our commitment to digitalization.

Contact: Christian Guillaume

christian.guillaume@sulzer.com

TOMRA Sorting GmbH

Stand 28

TOMRA Sorting supplies sensor-based ore-sorting technology for the mineral processing industry. The company’s technology offers effective material separation in various mineral and ore applications, such as in the processing of gold, diamonds, gemstones, industrial minerals and metal recovery from slag. World-wide, numerous TOMRA Sorting systems are already contributing to more energy-efficient and cost-effective pre-concentration, as well as material recovery. These solutions help to extend the life of mining operations and increase the value of ore deposits.

Contact: Oxana Penning

Worley Chemetics

Stand 54

Worley Chemetics is a leading provider of technology, solutions and equipment fabrication for sulphuric acid, chlorine chemicals and other specialty chemical facilities. Since 1964, we have been servicing worldwide customers in the chemical, oil & gas, fertilizer, pulp and paper industries. Chemetics technology helps customers to achieve higher capacities and reliability, lower their operating costs, substantially decrease emissions, improve safety and maximize long-term profits. Our CORE-SO2™ Sulphuric Acid Plant technology unlocks green fertilizer and sustainability goals. It decreases environmental footprint and greenhouse gas emissions, recovers CO 2 -free electrical power and enhances profitability. The small physical size of CORE-SO2™ confers significant construction advantages, while low internal gas flows and fewer pieces of equipment enable modularisation.

Contact: Mike Fenton