Nitrogen+Syngas 394 Mar-Apr 2025

19 March 2025

New boilers enhance performance and reliability

AMMONIA PLANT REVAMP

New boilers enhance performance and reliability

A European ammonia plant, has successfully restarted following a revamp of the process gas cooling section, executed by Casale. Casale replaced the outdated boilers located downstream of the secondary reformer with three new double-tube type boilers supplied by Arvos. The new boilers were installed in the same location as the previous ones, minimising investment costs and plant modifications. The more robust and reliable design of the Casale-Arvos boilers has resulted in enhanced overall performance and reliability of the ammonia plant.

In Kellogg-designed ammonia plants, the traditional arrangement includes two parallel process gas coolers (PGC), a bayonet water tube type and a vertical fire tube type. Process gas enters these units at temperatures exceeding 1,000°C, and boiler feed water (BFW) is used to cool the gas. However, several inherent design flaws in these PGCs lead to reliability issues:

Primary PGCs (bayonet water tube design)

- Sludge deposition: BFW deposits accumulate in the bayonet end cap, causing blockages and local overheating.

- Tube vibration: Flow-induced vibrations from gas movement increase the risk of tube damage.

- Frequent failures: Tube bundle replacements are common, requiring spare parts and high maintenance costs.

Secondary PGCs (fire tube design)

- Lower tube sheet issues: Sludge deposition reduces cooling and leads to overheating and welding failures.

- Steam blanketing: Inadequate riser nozzle placement leads to steam bubbles accumulating, reducing cooling efficiency and causing welding failures.

These reliability challenges necessitated frequent shutdowns, higher capital costs for spare parts, and increased maintenance.

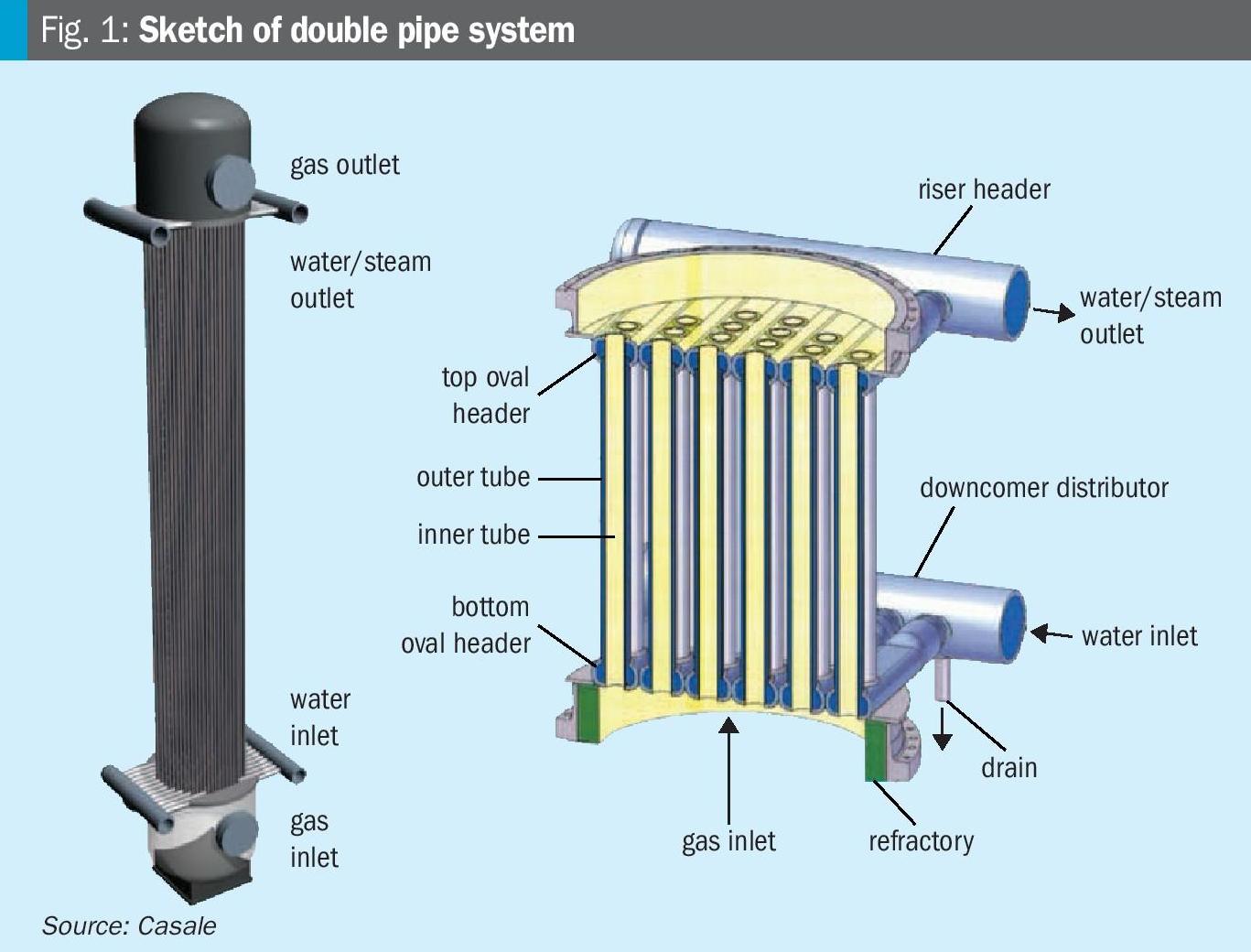

The Schmidt’sche® Double Tube System

The Schmidt’sche® double tube system, established for over 50 years in ethylene and gasification plants, has been adapted for ammonia applications (see Fig. 1). Its key features include:

Design principles:

- Combines fire and water tube designs.

- Utilises coaxial double tubes welded to oval headers, ensuring robust construction and flexibility to accommodate thermal stresses.

- Natural circulation of BFW prevents sludge deposition and steam blanketing.

Operational advantages:

- Enhanced cooling: water flows between the inner and outer tubes, converting into steam and optimising heat exchange.

- No flow-induced vibrations due to defined gas and water flow paths.

- Lower wall and material temperatures reduce thermal stresses, increasing reliability and lifespan.

Maintenance benefits:

- Full penetration, crevice-free welds prevent corrosion and ensure durability.

- Modular construction allows for the replacement of individual tube elements, reducing downtime and costs.

Proven reliability in ethylene and gasification plants

The Schmidt’sche® double tube system has proven its robustness in severe environments. The design has demonstrated success in over 7,000 units in ethylene and gasification industries, operating in harsh conditions with high temperatures, pressures, and corrosive environments.

Ethylene plants

- Operates cyclically with process gas temperatures of ~900°C and pressures up to 10 bar.

- Water-steam systems handle pressures of 100-120 bar.

Gasification plants

- Handles gas at up to 900°C and 27-50 bar with water-steam pressures of 50-115 bar.

- Successfully operates under high fouling, metal dusting, and hydrogen attack conditions.

Adaptation for ammonia plants

- The conditions in ammonia plants are less severe, making the design highly reliable.

- The double tube system’s experience in harsher environments ensures confidence in ammonia applications.

Fertiberia Palos case study

The transition of the Schmidt’sche® double tube system into ammonia plants is a story of innovation meeting necessity. Traditional process gas coolers in ammonia facilities, particularly those in older Kellogg-designed plants, have long been a source of problems for plant operators. The opportunity to upgrade these systems with proven technology from the ethylene and gasification industries offered a promising solution.

The first ammonia plant to benefit from this breakthrough is a typical MW Kellogg plant located in Palos (Spain), with a production capacity of 1,175 t/d. This facility, built decades ago, relied on the older vertical PGC designs downstream of the secondary reformer. Like many plants of its era, it faced ongoing reliability issues with the bayonet water tube and fire tube systems. When Casale and Schmidtsche Schack joined forces, they took a comprehensive approach to address these challenges.

Design and engineering

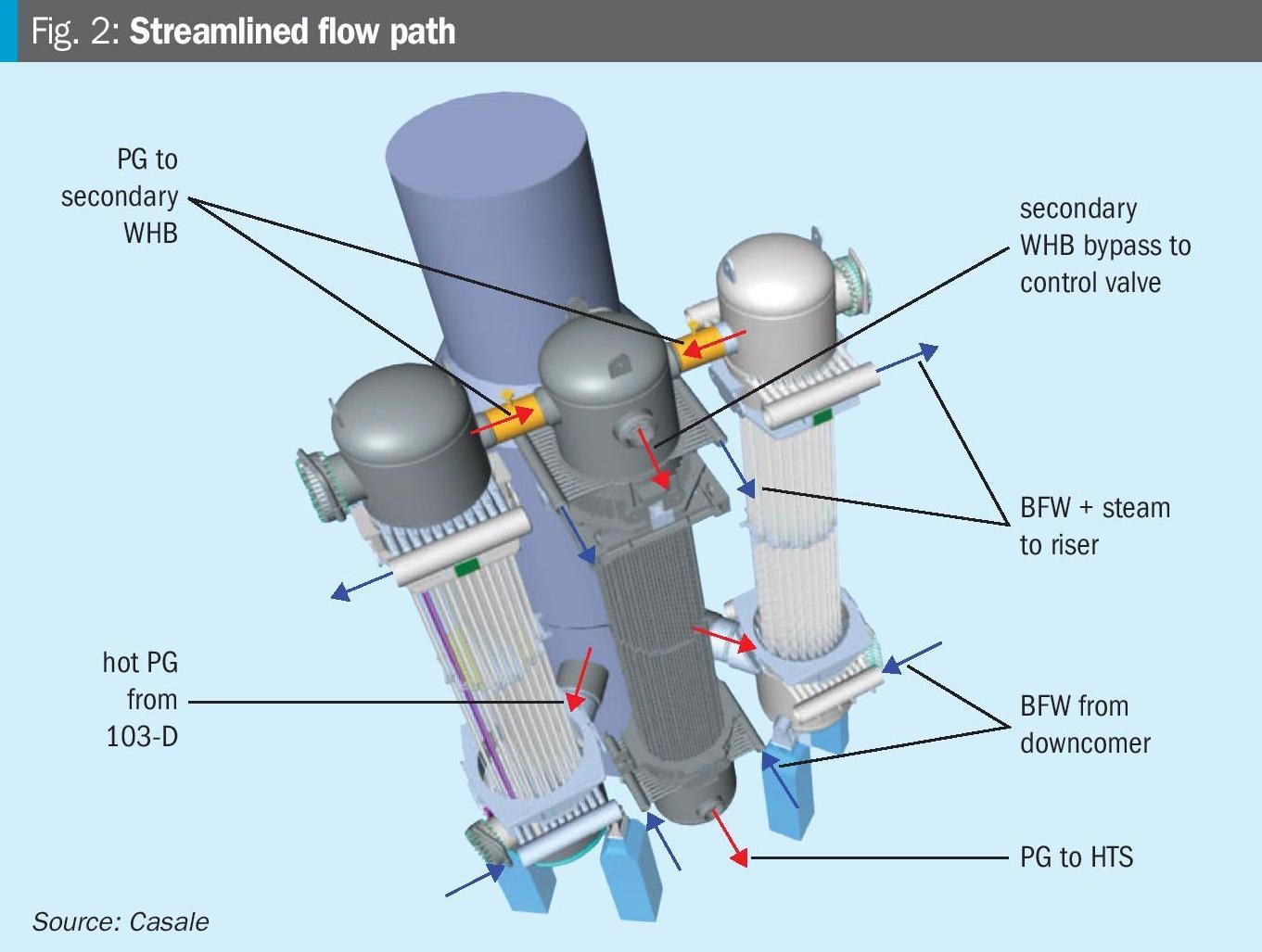

Schmidtsche Schack supplied the new double tube PGCs and redesigned risers and downcomers. Casale performed the detail engineering, including piping, civil, and instrumentation modifications and was responsible for the suitability assessment for existing plant (structures, foundations etc.).

A laser scan of the existing plant ensured precise integration.

One of the most pressing considerations was space. The area around the secondary reformer is notoriously cramped in most Kellogg plants, making it challenging to introduce new boilers without substantial modifications. The team tackled this issue head-on by designing the replacement PGCs to fit onto the existing positions of the outdated units. This clever adaptation not only saved on capital costs but also preserved the plant’s thermal efficiency by avoiding the need for long transfer lines that could lead to heat losses.

The retrofit involved installing three new double tube PGCs, carefully tailored to the plant’s requirements. The first two units (1101-CA and CB) were placed on newly constructed plinths, while the third unit (1102-C) was supported by the existing steel structure of the secondary reformer. This hybrid approach minimised construction time and costs while maintaining the integrity of the overall setup.

The installation also introduced several modern features. Unlike the original design, which included an external water jacket prone to hidden cracks and maintenance issues, the new 1101-CA and CB units were designed only with lined refractory in the hot channels. This improvement made it easier to detect refractory failures through sensitive paint systems, ensuring early intervention and reducing the risk of extensive damage. To connect the new boilers seamlessly to the existing system, a transition piece was added downstream of the secondary reformer outlet.

The hot gas from the secondary reformer now follows a streamlined flow path (Fig. 2). It enters the hot channels of the 1101-CA and CB boiler units, where it is cooled as it rises, before being directed into the top channel of 1102-C for further cooling as it descends. A bypass line was incorporated into the design of 1102-C to provide greater flexibility in controlling the downstream high-temperature shift (HTS) inlet temperature, which plays a crucial role in optimising reactor management throughout the life of the catalyst.

The installation plan

The installation of the new boiler was carried out during an extended turnaround in late spring 2024, which also included other activities, such as the replacement of the refractory lining inside the secondary reformer. Fertiberia was responsible for dismantling old boilers, installation of the new ones and subsequent commissioning and start-up.

In the absence of other activities, the WHB replacement could be completed in less than four weeks, with around-the-clock work facilitated by effective project planning and monitoring.

The installation sequence involves lifting and positioning 1101-CA/CB vertically (Fig. 3). They are initially supported at the base with wooden logs and secured by suspending them from the crane. Once this is done, the reinforcing frame is dismantled, and the exchanger is lifted, inserted into the plant structure, and placed on its pillar foundation (Figs 4-6).

Once the welding of the transfer line joints was completed, PWHT and NDT were performed.

Pre-commissioning – dry-out & boil-out

Prior to proceeding with the dry-out and boiling-out processes, the entire circuit was filled with water, and the spring hangers were unlocked.

The dry-out and boiling-out processes were performed simultaneously to allow for the drying of the secondary reformer at the same time. The boiling-out process lasted a total of 74 hours, after which the chemical solution was drained, and the circuit was rinsed twice with clean water.

Fertiberia requested an inspection of the steam drum, necessitating 6-7 additional flushes to cool it down. Once the steam drum was sufficiently cool, it was opened for inspection. The internal surfaces were found to be clean, with no debris, scales, or other residues. The steam drum was then closed and prepared for start-up.

Next, another procedure, recommended by Solarca (the chemical cleaning subcontractor), was carried out. This procedure, called magnetite accelerated formation, involved re-boiling the circuit at approximately 40 bar and 250°C for a specific period.

Finally, the dry-out process continued until the operating temperature of 1,050°C was reached, at which point the plant was started directly.

Start-up

After completing boil-out process, Fertiberia prepared the waste heat boilers for operation and started the ammonia plant up. In parallel with the startup activities, Fertiberia performed the steam blowing of high-pressure steam line to syngas compressor turbine.

After three days, on July 29th 2024, the plant started to produce ammonia at 85% load, without any issue. Performance of the boilers is very satisfactory, with a final temperature downstream of 1102-C of 345°C and a bypass 27% open.

Futureproofing the plant

One of the most exciting aspects of this retrofit is its preparation for future technological advancements. The new PGCs were designed to handle a potential stream of green hydrogen, enabling the plant to be hybridised by up to 40%. This forward-thinking feature reflects the growing trend toward decarbonisation in the ammonia industry, where green hydrogen is increasingly being viewed as the key to reducing greenhouse gas emissions. As green hydrogen becomes more accessible and cost-effective, the upgraded plant will be able to integrate it seamlessly, supporting a cleaner and more sustainable ammonia production process.

Conclusion

The replacement of traditional vertical PGCs with the Schmidt’sche® double tube system represents a major advancement in ammonia plant reliability and efficiency. By leveraging proven technology from ethylene and gasification industries, Casale and SCHMIDTSCHE SCHACK have introduced a robust solution tailored to ammonia applications. The first installation in an ammonia plant marks a significant milestone, with broader implications for modernising aging industrial infrastructure.