Sulphur 417 Mar-Apr 2025

19 March 2025

Producing sulphuric acid from gas streams with variable SO2

The first installed combination of a regenerative SO2 scrubbing system with a sulphuric acid plant using Worley Chemetics’ CORE™ reactor technology started up in November 2022. The combination of these technologies allows production of high-grade sulphuric acid from gases with low and/or fluctuating SO2 concentrations. C. Trujillo Sanchez and R. Dijkstra of Worley Chemetics report on the design concepts of this integrated process, highlight where it is most effective and report on the start-up and first years of operation of the plant.

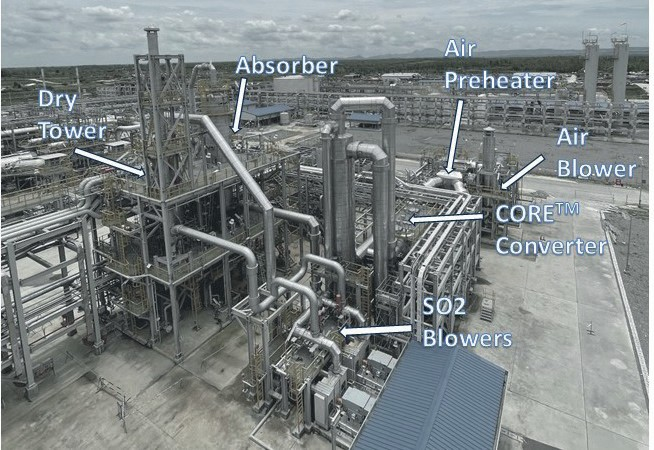

Jambaran Tiung Biru site.

The management of sulphur dioxide (SO2) emissions is a critical concern for various industrial sectors. SO2 emissions arise from the combustion of waste gases containing hydrogen sulphide (H2S) within the oil and gas sector. Additionally, the metallurgical industry contributes to SO2 emissions through off-gases that exhibit varying concentrations of this pollutant. A notable challenge faced by both industries is the fluctuation in SO2 levels in their emissions, which is influenced by the composition of their source materials.

The variation in SO2 concentration presents a significant challenge for the conventional production of sulphuric acid using the double contact double absorption (DCDA) process. This process requires mixing SO2 with air to achieve a concentration between 5% and 13% by volume and an O2 to SO2 ratio above 0.9. The mixed gas is then directed through adiabatic catalyst beds, with gas heat exchangers installed after each bed to cool the process gas before further reactions occur. If the SO2 concentration is too high, the temperature in the first catalyst bed can exceed the safe limits for vanadium pentoxide, leading to irreversible damage to the catalyst. Conversely, if the SO2 concentration is too low, the plant falls below its autothermal threshold and catalyst temperatures cannot be maintained, resulting in a significant reduction in the conversion of SO2 to SO3 or need for supplemental fuel which increases operating cost. This inefficiency may prevent the plant from meeting environmental emission standards or lead to excessive operating costs. Low SO2 concentrations also result in a rapid increase in size of the DCDA acid plant leading to high capex.

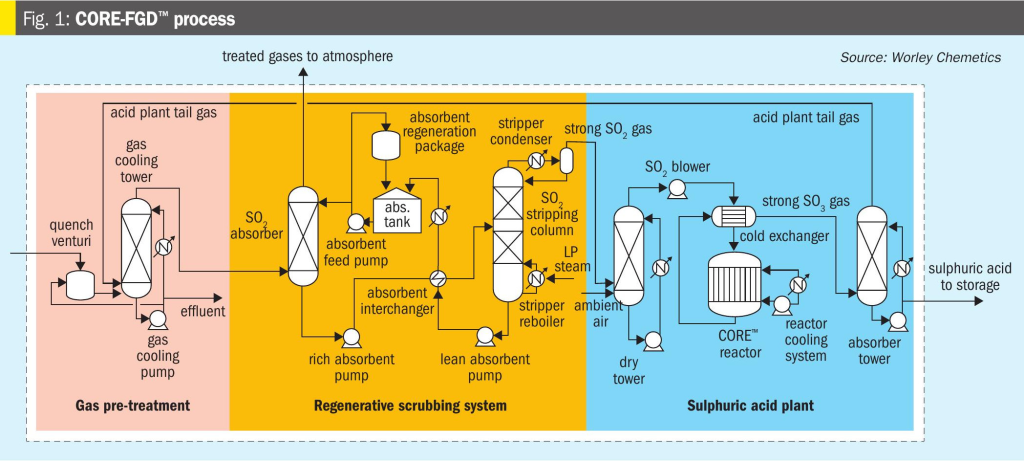

A solution for applications where the SO2 content is too low to allow direct conversion in a DCDA process is the CORE-FGD™ (CORE process for Flue Gas Desulphurisation) process offered by Worley Chemetics. This system provides a versatile and cost-effective solution for gases with low and/or fluctuating SO2 concentrations, with the further benefit of reduced plant size and operational versatility of the CORE™ technology.

The CORE-FGD™ process

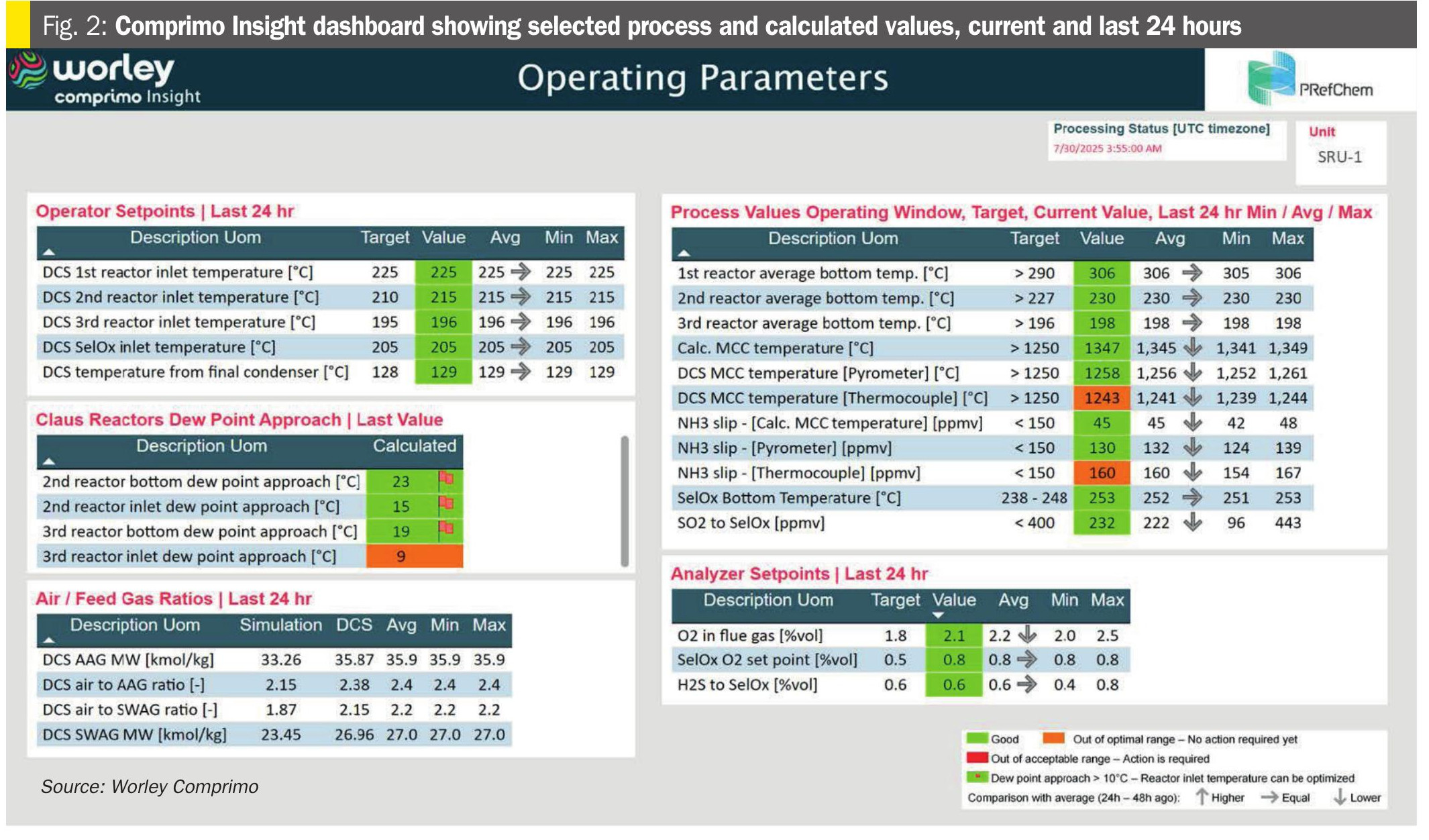

The CORE-FGD™ process produces sulphuric acid utilising three main process sections:

• Flue gas pretreatment

• Regenerative SO2 scrubbing

• Sulphuric acid production

Fig. 1 shows a simplified schematic of the three main sections. The combined process provides a versatile platform that can be easily adapted to fluctuating inlet SO2 concentrations and/or varying flue gas characteristics. Due to the customisable flue gas pretreatment system and the regenerative scrubber a virtually pure SO2 gas stream is produced that is efficiently converted to sulphuric acid. Additionally, due to the benefits of the CORE reactor technology the plant footprint and equipment count is significantly reduced compared to a conventional acid plant. It should be noted that all process sections can be provided as a single package by Worley Chemetics allowing the most suitable solvent licensor to be used for the project.

Gas pretreatment

The gas pretreatment section can be customised to handle any contaminants contained in the incoming gas. Generally, a quenching step as shown in Fig. 1 is required to create a cool saturated gas. However, much more elaborate gas cleaning systems may be required if the off-gas contains dust, metal fumes, halogens or other undesired components. If these impurities are not effectively removed, they may contaminate the scrubbing solution and/or lead to fouling in the scrubbing system. In these cases, the feed gas is conditioned in a gas pre-treatment system tailored to the specific impurities present in the feed gas. In the case of the oil and gas industry, where sulphur containing waste gases are created, the waste gases are first passed through a thermal oxidiser or incinerator to convert oxidise the hydrocarbons to CO2 and the H2S and other sulphur species to SO2. After the incinerator, the gas is cooled to recover valuable energy and is quenched/ scrubbed to remove particulates and other impurities. Finally, the gas is passed through mist eliminator candles to remove sulphuric acid mist.

Regenerative scrubbing

The regenerative scrubbing system is designed to capture the SO2 from the gas and delivers the captured SO2 as a highly concentrated SO2 product stream. This makes it particularly suitable in situations where SO2 gases exhibit significant variability in concentration and/or are too diluted for direct processing in a sulphuric acid plant. The gas leaving the pretreatment is directed through an absorber, where it interacts with an SO2-selective solvent (typically an aqueous amine solution). After absorption, the treated gas, with the SO2 removed by the amine, can be safely released into the atmosphere. Subsequently, the SO2-enriched amine is routed to a stripping column, where it undergoes regeneration via steam stripping. The gas emerging from the stripper is recovered as pure SO2 stream, saturated with water.

It should be noted that the regenerative scrubbing system can also include a second absorber column to capture CO2 which can be recovered as a separate stream for sites looking at carbon capture. In this case the removal of SO2 is a prerequisite for obtaining a pure CO2 product.

Sulphuric acid plant

In the sulphuric acid plant process, the SO2 gas from the regenerative scrubbing area is converted to SO3 to produce acid. Oxygen (ambient air, oxygen enriched air or pure oxygen) is added to gas from the regenerative scrubber to provide the oxygen necessary for conversion of the SO2 to SO3. The gas is then dried in a drying tower. If air is used to provide the oxygen then a dry gas is created with approximately 19 vol-% SO2 which is passed through a heat exchanger to increase the gas temperature and enters the CORE™ reactor to produce SO3.

CORE™ reactor

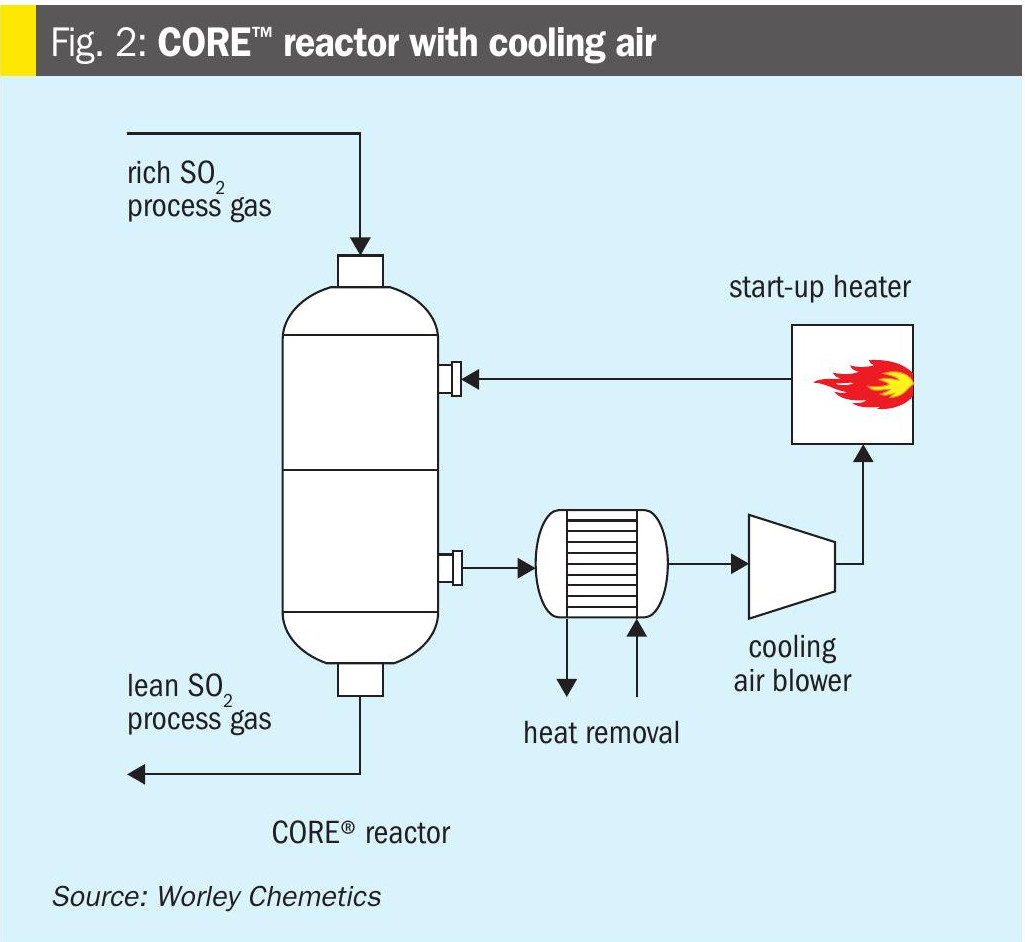

The CORE™ reactor is a tubular reactor with tubes containing a vanadium pentoxide catalyst. The tubes are continuously cooled on the exterior with a cooling medium (salt or air), maintaining the reaction temperature in a narrow range under all operating conditions. Fig. 2 shows the basic operation of a CORE™ reactor with cooling air. Cooling air is directed over the exterior of the CORE™ using a blower. During start-up, when the system is cold, a start-up heater is used to preheat the catalyst with circulating air before introducing process gas or during hot standby. As the reactor begins generating heat, the cooling air warms up and must be cooled before being recirculated into the CORE™ . This creates an opportunity for energy recovery. Large reactors are designed with molten salt cooling instead, which is more compact and consumes less power for coolant recirculation.

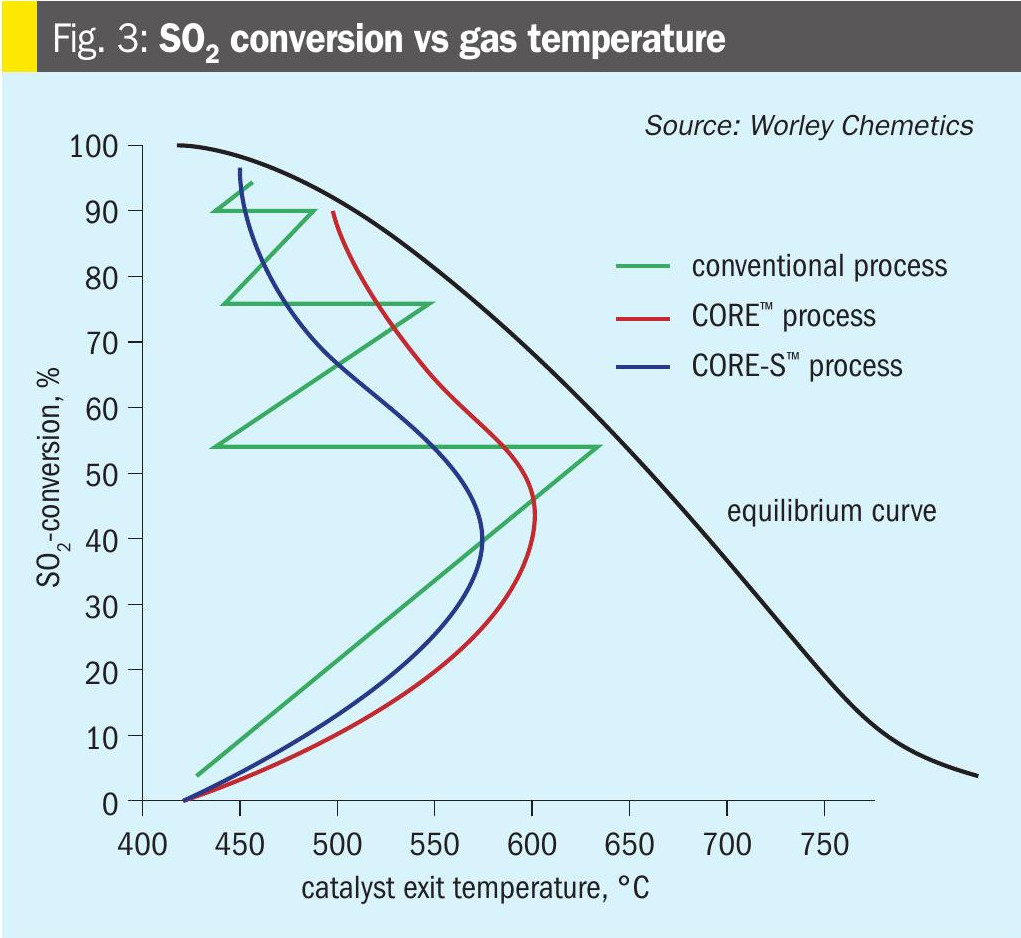

Because of this continuous cooling, the reactor can achieve single pass conversions of up 97% and operate with feed SO2 concentrations between 0 to 20 vol-% using air as the diluting medium, or between 0 to 60 vol-% when using pure O2 as a diluting medium. Fig. 3 shows the difference between the conversion of the conventional acid plant, CORE™ (air cooled), and CORE-S™ (salt cooled). Molten salt temperatures increase slower as compared to air due to the higher energy density of molten salt, resulting in higher conversion rates. If the unconverted SO2 (and O2) can be recycled it is beneficial to design the reactor with lower single pass conversion as this reduces overall cost.

The energy in the hot reactor outlet gas is recovered by preheating the incoming feed gas. This dual-purpose heat exchange enhances energy efficiency and results in a safe entry temperature into the absorption tower. The cooled gas passes through the absorption tower, where essentially all the SO3 in the gas is removed by absorption in sulphuric acid. Since a single pass through the CORE™ can achieve up to 97% conversion, this is generally not sufficient to achieve environmental limits. Therefore, the gases leaving the absorption tower are directed back to the gas pretreatment to cool the gas and remove the unconverted SO2 in the regenerative scrubbing system. This also has the advantage that there is only one discharge location for the process that requires permitting. The regenerative scrubbing system can be designed to meet local environmental requirement and can discharge as low as 50 mg/Nm³ without further treatment.

Energy recovery within a CORE-FGD™

Within the CORE-FGD™ system there are opportunities for energy integration and/ or energy export. Generally, the regenerative SO2 scrubbing system will be the main user of thermal energy (low pressure (LP) steam) whereas excess thermal energy is available from the sulphuric acid plant and the gas pretreatment area. In the gas pretreatment, heat exchangers can capture usable energy from the hot feed gas stream. Condensing heat exchangers have been successfully used to maximise energy recovery. The sulphuric acid plant has excess energy from the exothermic reactions involved in converting sulphur dioxide (SO2) to sulphuric acid. This energy can be advantageously captured as LP steam and used in the regenerative scrubbing system although production of HP steam is also possible. The energy requirements in the regenerative scrubbing system can be reduced by re-using the energy from the stripping column overhead stream. Mechanical vapour recompression has been successfully applied and can reduce the energy required in the regenerative SO2 scrubbing system by over 75%.

First CORE-FGD™ plant project

In 2017 Shell Global Solutions, working together with Zeeco and Worley Chemetics, signed a contract with Pertamina EP CEPU (PEPC) for the supply of a process design package (PDP) and critical equipment for a CORE-FGD™ system for the Jambaran Tiung Biru (JTB) gas processing facility in East Java, Indonesia. The JTB site is a gas processing facility for sweetening and compression of raw gas from six new sour gas wells in the area and has a design capacity of 192 million std. ft3/d. After extensive reviews, PEPC selected the Selexol process for the acid gas enrichment unit and decided that the acid gases from the Selexol unit would be converted into energy (steam) and sulphuric acid. At full capacity the acid gas contained enough sulphur species to produce approx. 377 t/d sulphuric acid. The sulphuric acid produced was to be sold to a nearby sulphuric acid user.

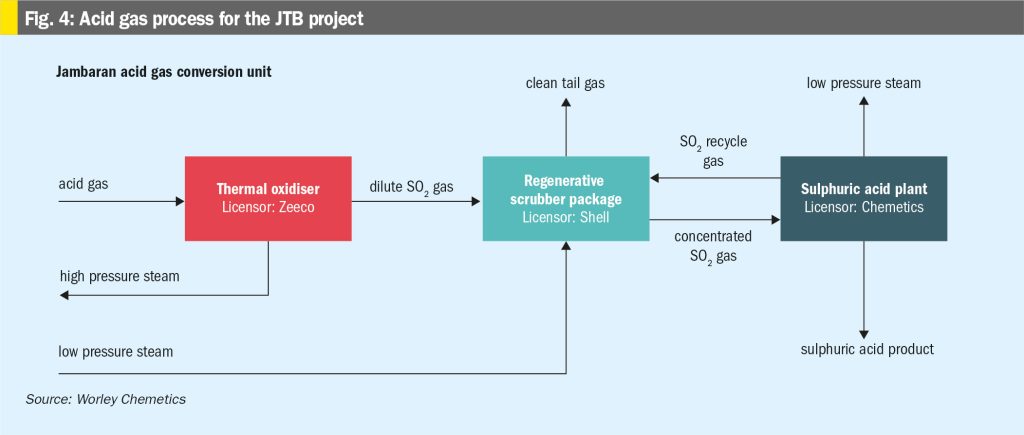

The project was completed in two phases. The first phase, completed in 2018, consisted of the PDP/basic engineering package for the entire acid gas unit that would allow PEPC to obtain firm pricing for the equipment. The acid gas conversion unit consists of three packages as indicated in Fig. 4:

• Thermal oxidiser: Waste gas incinerator c/w dual HP steam boilers.

• Scrubber package: Incinerator gas pretreatment (quench / mist removal) + Shell Cansolv regenerative scrubber system.

• Sulphuric acid unit: Sulphuric acid plant using CORE™ technology.

The second phase saw PT Rekayasa Industri (Rekind) commence as the overall EPC contractor for the entire gas processing facility in 2019. In 2020, Rekind awarded the engineering and procurement (EP) contract for the sulphuric acid unit to Worley Chemetics/PT Enviromate Technology International on a lump sum basis. At the same time, Zeeco was contracted to supply the incinerator package and Shell Global Solutions delivered the proprietary equipment for the Cansolv regenerative scrubbing system. Detailed design and supply of the balance of materials, as well as the overall integration of the three packages was done by Rekind.

The target start-up date for the gas processing facility was mid 2021. Similarly to many other projects, the COVID19 pandemic caused delays. After a brief shutdown of the site in early 2020, construction re-commenced, and raw natural gas from the first production well was introduced into the facility in July 2022. Commissioning delays on the acid gas enrichment unit (Selexol) meant that the first acid was not produced until early November 2022.

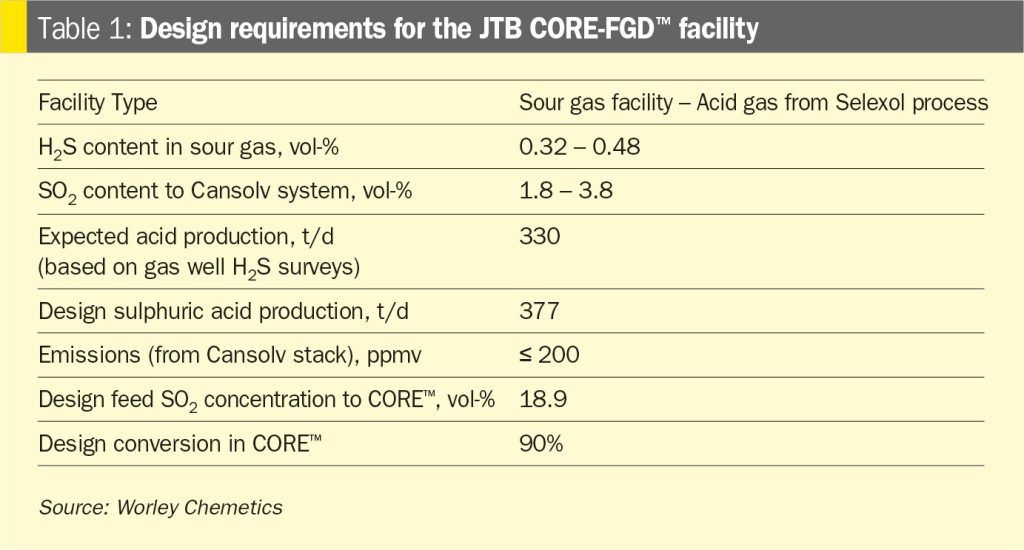

Sulphuric acid plant design

Table 1 summarises the site design criteria for the sulphuric acid plant. With a sour gas application with variable feed H2S content, a CORE-FGD™ with an air-cooled CORE™ reactor was a perfect fit for this plant.

The key process design features included in the design of the plant were as follows:

• plant turndown between 20 and 100% capacity;

• autothermal sulphuric acid plant operation above 6% SO2;

• dual (duty and standby) SO2 blowers and cooling air blowers to comply with site requirements;

• hazardous area classification for entire plant due to location in gas processing facility;

• electric preheat system to enable plant start-up without need for hydrocarbon fuels;

• variable speed drive for blowers to reduce power consumption; SARAMET® alloy towers and piping;

• energy recovery from CORE™ reactor producing LP steam;

• ability to remain in hot-standby for an unlimited period, ready to receive SO2.

Fig. 5 shows the compact design of the CORE™ acid plant, highlighting the relatively small size of the CORE™ reactor compared to the rest of the facility. Fig. 6 shows the gas inlet vestibule of the CORE™ reactor with the tubes holding the catalyst clearly visible.

Fig. 5: JTB sulphuric acid plant, Indonesia

Fig. 6: CORE™ reactor top vestibule

Sulphuric acid plant performance

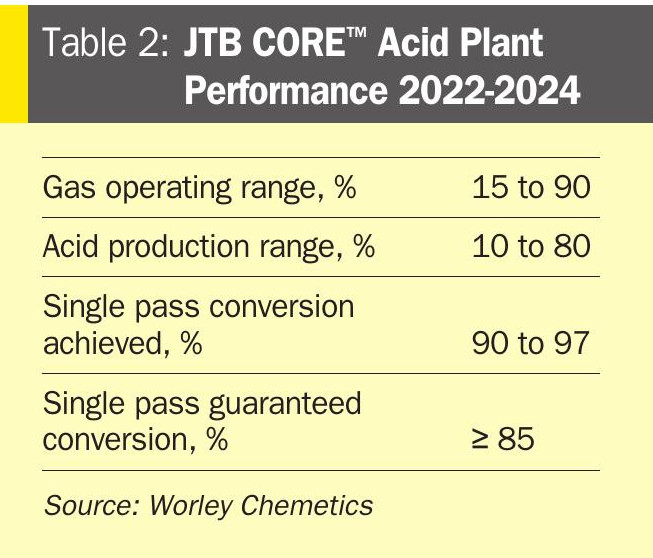

Over the past two years, the plant has operated continuously and has produced sulphuric acid of high quality. Acid production has been lower than anticipated due to lower-than-expected sulphur content of the raw gas and upstream process issues. These upstream process issues resulted in prolonged operation at low rates and frequent process interruption that showcased the ability of the CORE™ reactor to remain in hot standby mode as its capability to operate at very low rates with ease. Table 2 show the some of the CORE-FGD™ process operating ranges for the past years. During this period the Cansolv regenerative scrubber also met all environmental requirements for SO2 emissions.

Conclusion

The CORE-FGD™ system has demonstrated its effectiveness as a versatile solution for managing fluctuating SO2 concentrations in industrial emissions. By integrating flue gas pretreatment, regenerative scrubbing, and an advanced sulphuric acid production process, the system offers excellent operational flexibility and efficiency, even under challenging conditions such as the variable gas flows and low SO2 feed concentrations experienced at the JTB site.

The compact design and advanced technology of the CORE™ reactor contribute to a small plant footprint and enhanced energy recovery. The CORE-FGD™ system’s ability to reliably produce sulphuric acid at low operational costs and environmental impact, makes it an excellent alternative to conventional acid plants. ■