Price Trends

Market Insight courtesy of Argus Media

Market Insight courtesy of Argus Media

CF Fertilisers UK Limited, a subsidiary of CF Industries, says that it plans to permanently close the ammonia plant at its Billingham fertilizer complex in order to secure the long-term sustainability of its business in the UK. The Company intends to continue to produce ammonium nitrate (AN) fertiliser and nitric acid at the Billingham site using imported ammonia, as it has for the last 10 months following its decision to temporarily idle the plant in August 2022.

The CO2 emissions in a hydrocarbon fed hydrogen plant occur largely during the energy intensive syngas production step. Hydrogen production is therefore a major factor in the CO2 emission balance of an ammonia plant. BASF’s OASE® technologies for CO2 capture are capable of achieving cost-effective 99.99% carbon capture at scale. In this article Elena Petriaeva and Bernhard Geis of BASF investigate different grey and blue hydrogen production technologies.

The closure of CF Industries’ ammonia plant at Billingham, Teesside (see Industry News, page 8) marks the end of a long era for UK fertilizer manufacture. The facility was the last operating ammonia plant in the country, following CF’s decision to permanently close its site at Ince in Cheshire in June last year. Going forward, Billingham will now rely on imported ammonia as a feedstock to run the nitric acid and 625,000 t/a ammonium nitrate plants on the site.

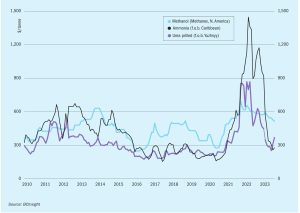

Ammonia prices have now dropped by about 50% from their highs a year ago. Gas prices have fallen, particularly in Europe, and peak fertilizer application season is over in Europe and North America, leading to slackening demand., leading to slackening demand.

Prior to the covid pandemic, sub-Saharan Africa had been the fastest growing market for new fertilizer demand. However, the combination of pandemic related disruption, followed by the dislocations caused by the war in Ukraine, have pushed up prices and led to falling demand across the continent.

Venkat Pattabathula , a member of the AIChE Ammonia Safety Committee, reports on the American Institute of Chemical Engineers’ Safety in Ammonia Plants and Related Facilities Symposium, held in Munich, Germany, from 20-24 August 2023.

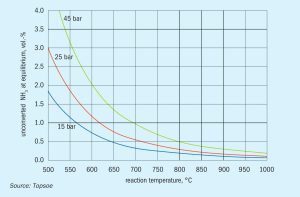

Large-scale ammonia cracking for conversion of ammonia to hydrogen is a proven technology with decades of industrial experience. Topsoe shares its experience within ammonia cracking and presents an improved and highly energy-efficient (96%) ammonia cracking technology, H2Retake™ , developed based on Topsoe’s proven technology and industrial experience.

While phosphate fertilizer production represents the main slice of demand for elemental sulphur and sulphuric acid, sulphur fertilizers continue to be a growing sector of demand due to changes in the way that we use sulphur.

Gustavo Horbach is EuroChem Group’s new Head of South America with responsibility for operations and strategic business development in the region. Gustavo was previously EuroChem’s VP for upstream production and investment projects in South America. He has been with the company since 2021.