Europe’s natural gas challenges

As Europe struggles to move away from its previous dependence on imported Russian natural gas, prices have been high and volatile, with a corresponding catastrophic impact upon domestic ammonia production.

As Europe struggles to move away from its previous dependence on imported Russian natural gas, prices have been high and volatile, with a corresponding catastrophic impact upon domestic ammonia production.

We are very pleased to be able to tell you that, as of this issue, Nitrogen+Syngas magazine has a new publisher. Or rather, an old publisher, as the magazine is now once again part of the CRU Group.

In a recent webinar, Chris Lawson, CRU’s Head of Fertilizers, gave the CRU view on what 2024 holds in store for the global fertilizer industry. Here are CRU’s top 10 calls for the year ahead:

The Saudi Arabian Mining Company (Ma’aden) has entered into a partnership with Metso and thyssenkrupp Uhde to develop and license an integrated process to reduce carbon emissions and recycle phosphogypsum in Saudi Arabia. A framework agreement between the three partners was jointly announced on 10th January.

Urea: December began on a positive note with a flurry of Egyptian urea sales and firmer prices for delivery to Brazil. The increase in values was short lived, however, and piecemeal demand in Europe was insufficient to halt the downward trend. By mid-December, buying interest from Brazil had fizzled out, although sellers breathed a sigh of relief when India’s NFL floated a new import tender on 21st December.

New regulatory developments in Europe are focusing attention on eliminating microplastic residues in soils by adopting biodegradable fertilizer coatings. Major technology licensors and engineering companies are also developing new coating technologies for controlled-release fertilizers (CRFs).

More than 700 delegates from 300 companies and 55 countries gathered at the EPIC SANA Lisboa Hotel, Lisbon, Portugal, 17-19 October 2023, for the Argus Fertilizer Europe 2023 conference.

Low demand, high gas prices and cheaper Russian imports of urea and ammonia are keeping a lid on European fertiliser production, prompting fears of permanent plant closures. ICIS’s Deepika Thapliyal, Sylvia Tranganida, and Aura Sabadus examine the challenges faced by the sector and the potential long-term impacts on the European fertilizer industry.

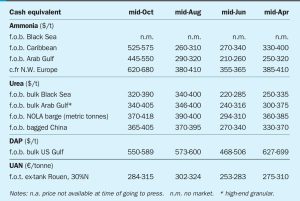

Market Insight courtesy of Argus Media. Urea: Prices in general fell further in late October. Suppliers in most regions were forced to accept lower than expected net-backs due to low import demand and high producer inventories. India was the exception with IPL securing 1.7 million tonnes of urea at $400-404/t cfr under its 20th October tender.

Market Insight courtesy of Argus Media