Press Release: Clariant to supply catalyst to SYPOX for world’s largest electric steam methane reformer

Clariant to manufacture catalyst for SYPOX e-SMR - planned to produce 150 tons of syngas a day

Clariant to manufacture catalyst for SYPOX e-SMR - planned to produce 150 tons of syngas a day

Clariant Catalysts signs strategic cooperation agreement with Shanghai Electric to 'jointly foster innovation in sustainable energy solutions'

Johnson Matthey Plc (JM) says that it has reached an agreement to sell its Catalyst Technologies (CT) business to Honeywell International, Inc. for £1.8 billion ($2.45 billion) on a cash and debt-free basis.

Clariant says that its ShiftMax 100 RE catalyst is now in operation at INERATEC’s Era One e-fuels production plant in the Frankfurt Hoechst industrial park. The facility will transform around 8,000 t/a of CO2 into up to 2,500 t/a of synthetic fuels and waxes. The e-fuels produced at the INERATEC facility can be used as […]

BASF says that it has signed a cooperation agreement with Plug Power to offer BASF’s advanced DeOxo catalysts as part of Plug Power’s hydrogen liquefaction plants globally to enhance their market offerings, improving reliability and cost efficiency. DeOxo catalysts, including the Purivate™ Pd15 product, offer exceptional performance at low temperatures, reducing the need for expensive […]

Axens says that it has completed the expansion of its Axens Catalyst Arabia Ltd site, aimed at providing local and regional partners with the latest tail gas treatment catalysts, in addition to the site’s legacy catalyst hydroprocessing manufacturing capacity. This makes Axens is the first and only company to produce tail gas treatment catalysts in the Middle East. The company says that the expansion consolidates its capacity to serve its regional customers to meet regulatory requirements and maximise sulphur recovery by up to 99.9%, minimising SOx emissions. The production site supplies the region’s refining and gas industries with the latest generation of Axens’ catalysts, capable of operating at lower temperatures than conventional catalysts, and resulting in lower energy consumption.

Clariant says that its MegaMax 900 methanol synthesis catalyst has been used in the successful startup of European Energy’s green methanol plant at Kasso, Denmark. The facility uses biogenic CO2 and green hydrogen to produce up to 42,000 t/a of green methanol. Clariant’s Applied Catalyst Technology (ACT) technical service team provided on-site support throughout the startup procedure, overseeing the catalyst loading, reduction, and startup. Clariant says that the catalyst is operating with excellent activity and stability despite the challenging conditions of CO2 -to-methanol conversion.

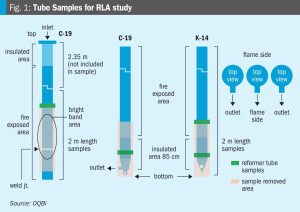

Muhammad Faisal Faraz and Abdullah Al Balushi of OQBi explain how by implementing a series of technical and process improvements, OQBi has successfully extended the lifespan of its reformer tubes by six years beyond the original design life of 100,000 hours.

Axens Catalyst Arabia Ltd to manufacture Tail Gas Treatment Catalyst on newly expanded site

Clariant's EnviCat N2O removal catalysts cuts 44,000 tons/month CO2e emissions at GNFC nitric acid plant in Gujarat, India