Sulphur+Sulphuric Acid 2024

A report on CRU’s annual Sulphur+Sulphuric Acid Conference, held in Barcelona, in early November.

A report on CRU’s annual Sulphur+Sulphuric Acid Conference, held in Barcelona, in early November.

Join us at the CRU Sulphur + Sulphuric Acid 2024 Conference and Exhibition in Barcelona, 4-6 November, for a global gathering of the sulphur and sulphuric acid community. Meet leading market and technology experts and producers, network, share knowledge, and learn about market trends and the latest developments in operations, process technology and equipment.

With increased demands to reduce SO2 emissions and lower energy consumption, Eduardo Almeida and Nelson Clark of Clark Solutions highlight the advantages of single absorption sulphuric acid plants compared to double absorption plants.

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.

A report on CRU’s annual Sulphur + Sulphuric Acid conference, which returned to being face to face meeting at the end of October 2022.

E. Almeida and B. Ferraro of Clark Solutions discuss how regular monitoring by simple testing of the towers in sulphuric acid plants can improve the reliability and lifespan of the plant.

A look at papers presented at CRU’s annual Sulphur + Sulphuric Acid conference, which was once again held virtually, in November 2021.

Corrosion is one of the most critical aspects regarding sulphuric acid plant lifespan. One important cause of corrosion in sulphuric acid plants is acid condensation from the process gas due to inadequate drying. E. Almeida, B. Ferraro, N. Clark, V. Machida and V. Sturm of Clark Solutions discuss this problem and how it can be avoided with proper tower and internals design.

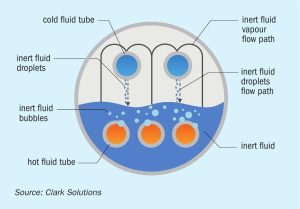

N. Clark, B. Avancini and V. Sturm of Clark Solutions discuss a novel technology, SAFEHX® , providing a new approach to the cooling of strong sulphuric acid. Prototype results are shown and indicate a safe and stable cost-effective technology. SAFEHX® can be extended to every heat exchanger system where corrosion, mixture risks, fouling, process liquid loss (or contamination) and temperature control are key concerns.

The coronavirus outbreak necessitated a ‘virtual’ CRU Sulphur + Sulphuric Acid conference last year, held in November 2020.