Detecting and preventing SO2 breakthrough

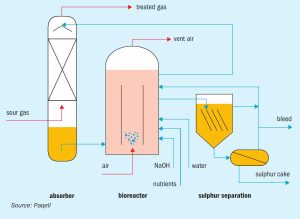

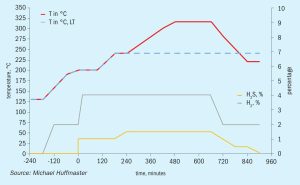

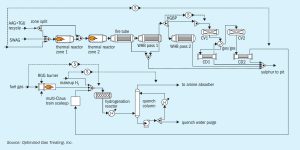

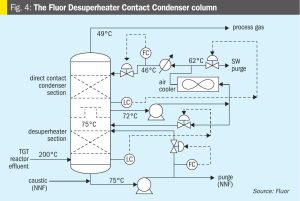

Fluor discusses the main causes, detection techniques, management methods and prevention procedures of SO2 breakthrough in the quench water system of a TGTU, with some unique design features for Fluor’s Desuperheater Contact Condenser.