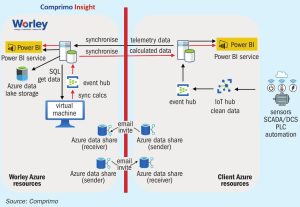

Digital tools to optimise the operation of your sulphur recovery unit

Comprimo has recently launched two new solutions to make the most of existing data and to improve customer’s operations and customer knowhow: Comprimo Insight – an intelligent sulphur plant dashboard, and Comprimo Immerse – a dynamic sulphur plant simulator. In this article, Comprimo goes into the details of how Comprimo Insight and Comprimo Immerse are being implemented for its customers.