Sulphur Industry News Roundup

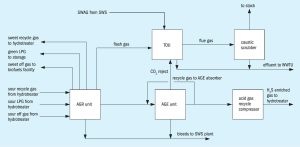

Haldor Topsoe and Comprimo® have announced a global strategic alliance to jointly license the TopClaus sulphur removal and recovery technology. TopClaus combines Topsoe’s energy efficient wet sulphuric acid (WSA) process with the industry-standard Claus process, enabling plant operators to handle acid gases and achieve sulphur removal efficiencies of above 99.9%. The Claus part of the unit recovers elemental sulphur from acid gases, and the tail gases from the Claus unit are then treated in the WSA unit, where the remaining sulphur compounds are converted into sulphuric acid.