Serra do Salitre project profile

EuroChem Group recently completed the purchase of the Serra do Salitre project from Yara International for $452 million. This one million tonne capacity Brazilian phosphate project is due to be completed in 2024.

EuroChem Group recently completed the purchase of the Serra do Salitre project from Yara International for $452 million. This one million tonne capacity Brazilian phosphate project is due to be completed in 2024.

The International Fertilizer Association (IFA) has signed a memorandum of understanding with the United Nations Food and Agriculture Organisation (FAO) over collaboration to support the FAO’s vision of transformative change and innovation in agriculture. Svein Tore Holsether, IFA Chair, signed the agreement at a live virtual signing in December together with FAO deputy director general Beth Bechdol. The agreement outlines collaboration to further shared goals and objectives with regard to the promotion of sustainable food and agriculture. Both parties will work together to raise awareness about the International Code of Conduct for the Sustainable Use and Management of Fertilizers (Fertilizer Code), promote education and knowledge transfer and continue their successful collaboration on fertilizer statistics.

The Bia Energy Operating Company says that it is evaluating a $550 million blue methanol plant at the port of Caddo-Bossier in Shreveport, Louisiana. The unit would have a capacity of 530,000 t/a of methanol using natural gas feedstock with downstream carbon capture, reducing CO2 emissions by more than 90% compared to other methanol plants. The company is expected to make a final decision in 1Q 2022, with construction expected to last approximately two years, and commercial operations to begin soon after.

Gordon Feller looks at Gasunie’s plans to build a new nitrogen plant at Zuidbroek to allow for the progressive shutdown of the Groningen gas field, one of the largest in Europe.

Catalytic converters are the heart and hub of sulphuric acid plants. Converter replacement of equipment that has come to the end of its life is an opportunity to make improvements to the performance, productivity, reliability, durability and plant emissions. NORAM discusses design and project execution considerations for SO2 catalytic converter replacement and Chemetics considers the challenges and opportunities of converter retrofits.

Fertilizer International presents a global round-up of current potash projects.

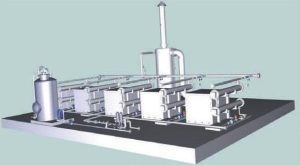

A move towards smaller scale feedstocks such as renewable energy and waste and biomass gasification is leading to increased focus on improving the efficiency of small-scale, modular plants.

In China, requirements for methanol to produce olefins, mainly propylene and ethylene, from coal, has driven much of the growth in global methanol demand over the past decade. However, a new wave of ethylene cracker investment may put a stop to new MTO plant building.

Nitrogen-rich wastewaters remain a major issue for fertilizer and other industries. Saipem’s new electrochemical technology, SPELL, is an important step towards the overall objective of zero industrial pollution. A complete engineering review of the technology, its alignment with all international applicable standards, and optimisation has now been concluded and the technology is ready for deployment for the removal of ammonium nitrogen from industrial waters and wastewaters. Saipem discusses the key features of SPELL and reports on the first two industrial references.

Although the number of new sour gas developments has slowed in recent years compared to the large boost of the previous decade, sour gas projects continue to be a major source of new sulphur production.