Who’s who in fertilizer handling and precision blending

An overview of the very latest in fertilizer handling and blending, including new contracts, company news and advances in technology.

An overview of the very latest in fertilizer handling and blending, including new contracts, company news and advances in technology.

BHP is committed to investing $5.7 billion to complete the first stage of the Jansen project and bring it into operation by the end of 2026. This under-construction Saskatchewan mine will then ramp up to produce more than four million tonnes of potash annually before the end of the decade.

Pejman Djavdan , CEO of Stamicarbon looks at the ways in which the fertilizer industry must grapple with issues such as decarbonisation, sustainability and more efficient use of nutrients.

Nitrogen+Syngas’s annual listing of new ammonia, urea, nitric acid and ammonium nitrate plants.

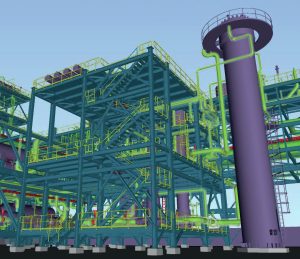

With the market for green ammonia set to grow significantly in the coming years, modularisation of ammonia plants can bring many benefits to new projects, including optimised cost, speed of delivery and reducing overall risks. thyssenkrupp Uhde is committed to further develop standardised, modular solutions for its clients. Tobias Birwe and Dustin Mayor explain the company’s modularisation concept.

Anglo American’s CEO Duncan Wanblad spoke in detail about the company’s new strategy for the Woodsmith mine during an annual results presentation on 23rd February. Selected highlights are provided below.

Anglo American recently unveiled the long-awaited strategy update for its large-scale Woodsmith mine project in the UK. Initial production of the company’s POLY4 polyhalite fertilizer is now scheduled to begin in 2027. The mine’s ultimate annual output has also been increased to 13 million tonnes.

Mining major Anglo American is to invest up to $4 billion to complete its Wood-smith mine project in the UK.

Mathijs Sijpkes, Nuria Pascual Vasco and Jan Hermans of Sulphurnet discuss the importance of a whole life cycle cost analysis at the conceptual design phase when making investment decisions about new sulphur processing facilities.

BASF says that its high-pressure regenerative CO2 capture technology HiPACT ® , codeveloped by BASF and engineering partner JGC Corporation will be used by INPEX, one of Japan’s largest exploration and production companies, in its Kashiwazaki Clean Hydrogen/Ammonia Project. This is Japan’s first demonstration project for the production of blue hydrogen/ammonia from domestically produced natural gas, the consistent implementation of carbon capture, utilisation and storage (CCUS) in domestic depleted gas fields and the use of hydrogen for power generation and ammonia production. The project is funded by the Japanese governmental organization New Energy and Industrial Technology Development Organization (NEDO).