Fertilizer International Index 2022

A complete listing of all articles and news items that appeared in Fertilizer International during 2022

A complete listing of all articles and news items that appeared in Fertilizer International during 2022

2022 was another very good year for Nutrien, the world’s largest crop nutrient company. The Canadian-headquartered fertilizer giant produces around 27 million tonnes of potash, nitrogen and phosphate products annually from operations and investments in 14 countries, distributing these to agricultural, industrial and feed customers across the globe. Its agriculture retail business, Nutrien Ag Solutions, also serves more than 500,000 farmers worldwide.

Swiss-headquartered sulphuric acid trading company ChemTrans Trading AG has announced the passing of its founder Bo Levander. In a statement on behalf of the family and company, Bo’s son Henrik Levander said:

Storing urea under hot and humid ambient conditions can be a chall enge. Several quality parameters of the urea product itself like moisture, temperature and particle size distribution are critical. Fluctuations of these parameters over time are also important and can lead to caking issues and complaints by clients. Off-spec product means big losses in revenue and results in a troublesome stream that has to be handled separately. Learning from each other’s experiences is vital to minimise and avoid these problems. n

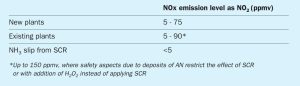

Highly efficient N2 O abatement technologies, coupled with the continually rising CO2 e price/ tonne are the driving forces behind nitric acid plant operators looking for increasingly sensitive and precise measurements of the N2 O mass emission. David Inward of Sick AG discusses new state-of-the-art emission monitoring technology which provides the measurements required.

Brazil’s agricultural industry continues to expand at the same time that most of its nitrogen fertilizer industry has shut down. Meanwhile, Venezuela continues to deal with the consequences of years of underinvestment and mismanagement, and elsewhere, gas discoveries in other parts of the continent have not led to the new plant construction boom that had once been hoped for.

A complete listing of all articles and news items that appeared in Nitrogen+Syngas magazine during 2022.

A complete listing of all articles and news items that appeared in Sulphur magazine during 2022.

Advances in technology, equipment and reagents are enhancing phosphate fertilizer production. Optimisation of standard equipment is also vital for ensuring process efficiency.

After two turbulent years, could the fertilizer market finally start to stabilise in 2023? Well, that’s what Dutch agricultural finance house Rabobank is predicting…