Unlock the true potential of your SRU

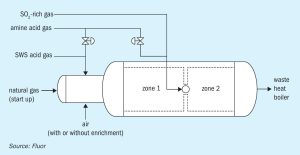

Fluor explores the versatile potential of oxygen enrichment for various revamp and debottlenecking opportunities.

Fluor explores the versatile potential of oxygen enrichment for various revamp and debottlenecking opportunities.

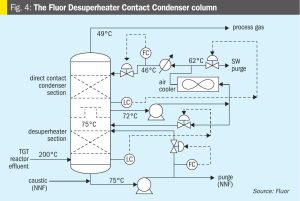

Fluor discusses the main causes, detection techniques, management methods and prevention procedures of SO2 breakthrough in the quench water system of a TGTU, with some unique design features for Fluor’s Desuperheater Contact Condenser.

A report on CRU’s annual Sulphur+Sulphuric Acid Conference, held in Barcelona, in early November.

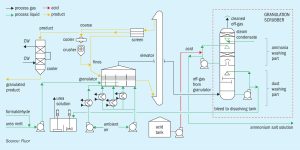

Marcus Weber of Fluor discusses degassing units for large scale sulphur recovery units, evaluating the pros and cons of various available commercial technologies with the emphasis on mega size sulphur recovery units and focussing on how technology can lower degassing capex via economy of scale for new facilities or existing facilities undergoing expansion.

Join us at the CRU Sulphur + Sulphuric Acid 2024 Conference and Exhibition in Barcelona, 4-6 November, for a global gathering of the sulphur and sulphuric acid community. Meet leading market and technology experts and producers, network, share knowledge, and learn about market trends and the latest developments in operations, process technology and equipment.

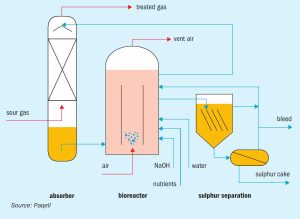

As environmental SO2 emission regulations become more stringent, tail gas treating options become limited. To potentially achieve lower opex and improved plot plan, utilising a biological desulphurisation process as an alternative to a conventional amine-based TGT unit is becoming of increased interest in the oil and gas industry. At the same time, demands for increased SRU capacity and reliability favour the use of medium and high-level oxygen enrichment.

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.

Following the completion of expansion work on the ultra-sour gas Shah field in May 2023, production has been ramped up. Occidental, which owns 40% of the Shah project and which operates the field in conjunction with ADONC Sour Gas, reported in July that it had achieved record output at Shah, with gross gas sales reaching 722 million scfd in Q2 2023 (equivalent to 1.1 billion scf/d of raw gas, which is 23% H2S and 10% CO 2 ). The expansion has taken processing capacity at Shah to 1.45 billion scf/d and forms part of the UAE’s plans to achieve gas self-sufficiency by the end of the decade. The expansion was conducted by Saipem, who were awarded a $510 million contract in 2021 to expand output from 1.3 billion scf/d to the current 1.45 billion scf/d. Work was completed two months ahead of schedule, according to Occidental.

Fluor investigates how SO2 impacts the Claus furnace temperature in an SRU and the ways to mitigate it. This article studies the extent of quenching experienced in the Claus furnace with varying amounts of SO2 in the Claus feed. A case study is presented based on real operating data of a refinery Claus plant with a feed gas cocktail that includes substantial SO2 recovered from a regenerative flue gas desulphurisation unit.

Fluor demonstrates how SRU/TGTU plants within sour gas facilities can facilitate the capture of CO2 and generate H2 by implementing advanced sulphur recovery technologies.