Sulphur + Sulphuric Acid 2020

The coronavirus outbreak necessitated a ‘virtual’ CRU Sulphur + Sulphuric Acid conference last year, held in November 2020.

The coronavirus outbreak necessitated a ‘virtual’ CRU Sulphur + Sulphuric Acid conference last year, held in November 2020.

A look back at some of the major events of 2020 for the sulphur and sulphuric acid industries, as well as a look forward as to how 2021 might look.

New approaches and novel processing schemes employing oxygen enrichment in sulphur recovery units have been developed and commercialised. In this feature Siirtec Nigi, Linde, Blasch, Fluor and RATE report on their latest developments.

Haldor Topsoe and Comprimo® have announced a global strategic alliance to jointly license the TopClaus sulphur removal and recovery technology. TopClaus combines Topsoe’s energy efficient wet sulphuric acid (WSA) process with the industry-standard Claus process, enabling plant operators to handle acid gases and achieve sulphur removal efficiencies of above 99.9%. The Claus part of the unit recovers elemental sulphur from acid gases, and the tail gases from the Claus unit are then treated in the WSA unit, where the remaining sulphur compounds are converted into sulphuric acid.

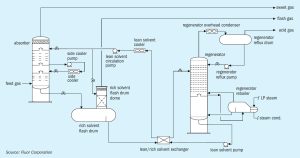

Fluor’s case study of recently constructed ultra-sour gas treating facilities provides new information about the operation of DGA-based AGRUs. B. Lynch and C. Graham of Fluor Corporation discuss how using this knowledge and leveraging the recent improvements to process simulators in the gas sweetening space, Fluor has developed an efficient, flexible, and cost effective solution in the two-stage absorption process to maximise mercaptan removal from ultra-sour gases with minimal equipment.

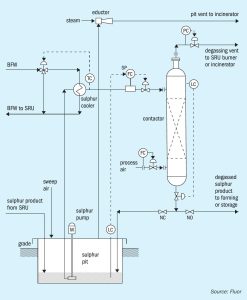

Fluor/GAA continue to strive to improve the performance of the D’GAASS out-of-pit liquid sulphur degassing technology based on commercial operating experience and ever-changing environmental emissions regulations. T. Chow and S. Fenderson of Fluor Energy & Chemicals/ Goar, Allison & Associates discuss operating experience that has led to the improvements of the new patent-pending third generation D’GAASS 3G technology.

R. Kranenburg of Duiker discusses the latest applications of SCO units in refineries and petrochemical complexes. The SCO unit is typically integrated in the sulphur recovery unit and is intended for processing ammonia, while also treating the tail gases from the upstream SRU.

New ammonia and urea plants in Nigeria and Ethiopia are part of a wave of new capacity in Sub-Saharan Africa, and may help pull up regional demand from its current low base level.

The Sixth Annual MESPON Forum took place 7-10 October at the Rosewood Hotel Abu Dhabi, where the global sour gas and sulphur community gathered for four days of networking, learning, and collaboration. This year’s theme highlighted new trends, innovations and best practices in the field of sour gas processing that enhance operations.

CRU’s Sulphur + Sulphuric Acid 2019 conference was held in Houston last November.