Nitrogen + Syngas 2023

CRU Events will host the 2023 Nitrogen + Syngas conference and exhibition at the Hyatt Regency Barcelona Tower in Barcelona, 6-8 March.

CRU Events will host the 2023 Nitrogen + Syngas conference and exhibition at the Hyatt Regency Barcelona Tower in Barcelona, 6-8 March.

Cansu Doganay of Lux Research takes a look at the current technology landscape for methane pyrolysis for producing low-carbon hydrogen from natural gas.

A review of the current slate of plans for green and blue ammonia production.

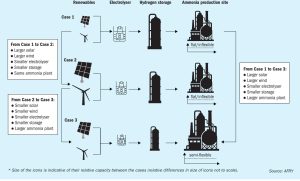

Due to the inherent nature of the renewable power, sizing eSyngas plants powered with renewable energy brings complexity normally not faced by natural gas-based facilities. In this article, Dr Raimon Marin and Dr Solomos Georgiou of AFRY discuss the application of AFRY’s state-of-the-art modelling tool to optimise the size and production of a green hydrogen system and a green ammonia plant based on given renewable power profiles and their associated variability (e.g., hourly, daily, seasonally, and annually).

Stamicarbon has won a contract for a large-scale urea project in China. The urea plant, with a production capacity of 3,800 t/d, will be the largest ever licensed by Stamicarbon in the country. The customer, the plant’s location and the value of the contract have not been disclosed.

Fulcrum BioEnergy says that it has successfully produced low-carbon synthetic crude oil using landfill waste as a feedstock at its Sierra BioFuels Plant, the world’s first commercial-scale landfill waste-to-fuels plant. Located outside of Reno, Nevada, Sierra will produce approximately 11 million gallons of renewable, low-carbon transportation fuels each year from approximately 175,000 t/a of landfill waste.

Air Liquide presents the results of an internal study to identify preferred natural gas-based plant configurations at a methanol capacity of 250 t/d. Delivering small capacity plants requires a focus on the total cost of ownership (TCO) for the economics to be successful, in addition to the CO 2 footprint of the operation. As found by this study, SMR concepts are naturally power balanced for standalone greenfield operations and show no particular advantage for power import in a brownfield setting. POX and ATR cases are greatly improved and even advantaged in a brownfield setting compared to SMR when shifting from power balance to power import cases.

Advanced Methanol Amsterdam (AMA) is a production facility, that will be realised in the Port of Amsterdam's Biopark, which is destined to produce advanced methanol that meets the European renewable energy directive (RED) requirements. Once completed, AMA will be the flagship production site for GIDynamics and GIDARA Energy and for its High Temperature Winkler (HTW ® ) gasification technology. AMA will also be the first of its kind green methanol unit designed by Casale.

At the organisation’s first face to face meeting since covid, in Vienna in early October, OPEC+ ministers agreed to cut global oil supplies by 2 million bbl/d in November. OPEC+ is a group of 24 oil-producing nations, made up of the 14 members of the Organisation of Petroleum Exporting Countries (OPEC), and 10 other non-OPEC members, including Russia. In a statement, the group said the decision to cut production was made “in light of the uncertainty that surrounds the global economic and oil market outlooks.”

A move towards so-called ‘sustainable aviation fuels’ (SAF) could see refineries having to recast their operations. What might this mean for sulphur production?