CO2 removal system analytics

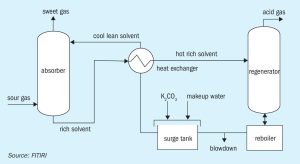

Arun Murugan and Mike Antony of FITIRI and Venkat Pattabathula of SVP Chemical Plant Services discuss the COORS Analytics system for more accurate prediction of the performance of a CO 2 removal system.

Arun Murugan and Mike Antony of FITIRI and Venkat Pattabathula of SVP Chemical Plant Services discuss the COORS Analytics system for more accurate prediction of the performance of a CO 2 removal system.

India’s power and renewable energy minister RK Singh has placed draft plans before the cabinet for the country’s refining and fertilizer sectors to switch to renewable ‘green’ hydrogen feeds. Other energy intensive sectors such as steel and transport are likely to follow. The policy suggests that refiners must have 10% of their hydrogen consumption generated from renewable electricity by the end of financial year 2023-24, rising to 25% by 2030. The comparable figures for ammonia/urea production are 5% and 20%, respectively. India is pursuing some of the world’s most ambitious renewable energy targets of 175 GW of renewable energy capacity by the end of 2022 and 450 GW by 2030.

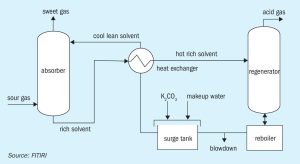

Tightening regulations and growing global competition are increasing the pressure felt by sulphuric acid plant operators to reduce emissions and improve energy output. Conservation of energy is a continuous focus for operators, and environmental communities have grown more vocal in their desire for greater emissions oversight. In this article, DuPont Clean Technologies examines simple, tried, and true tactics, as well as new products and designs that can be incorporated into existing plants to address operating efficiency and emissions and to help to prolong the life of the plant.

Preliminary engineering work has started on a renewable powerto-fertilizer plant in Kenya.

A consortium has unveiled plans to build one of the largest green hydrogen plants in the world in a bid to make Oman a leader in renewable energy technology. The $30 billion project is being developed by Oman’s state-owned oil firm OQ, green fuels developer InterContinental Energy and Kuwait government-backed renewables investor EnerTech. Construction is scheduled to start in 2028 in Al Wusta governorate on the Arabian Sea. It will be built in stages, with the aim to be at full capacity by 2038, powered by 25 GW of wind and solar energy. Two years has already been spent on solar and wind monitoring analysis for the development. According to the consortium, the site chosen has the optimal diurnal profile of strong wind at night and reliable sun during the day, and is also located near the coast for seawater intake and electrolysis.

A round-up of current and proposed projects involving non-nitrogen synthesis gas derivatives, including methanol, hydrogen, synthetic/substitute natural gas (SNG) and gas- and coal to liquids (GTL/CTL) plants.

Plans to decarbonise power production and shipping are leading to increasing interest in using ammonia as a fuel, but technical and economic barriers still remain to be overcome.

Maire Tecnimont SpA says that its subsidiaries MET Development, Stamicarbon and NextChem have collectively begun work on a renewable power-to-fertilizer plant in Kenya. MET Development has signed an agreement with Oserian Development Company for the development of the plant at the Oserian Two lakes Industrial Park, on the southern banks of Lake Naivasha, 100 km north of Nairobi.

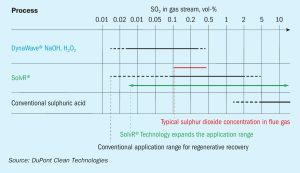

The internals of ammonia synthesis converters are generally made of austenitic stainless steel to withstand the harsh operating conditions (high temperature, high pressure and synthesis gas containing hydrogen and ammonia). Since nitriding is the most critical material degradation for the converter internals, Casale has set up a large nitriding analysis campaign. In the last decade, samples of materials operated under different pressures and temperatures and for different time spans have been tested and analysed. The data obtained has been used to increase nitriding knowledge and to establish a correlation to predict nitriding rate to allow the most suitable material and relevant thickness to be selected. L. Redaelli and G. Deodato of Casale report on how this correlation was established and provide valuable insight on this phenomenon and how to predict and control it.

M. Østberg and M. Rautenbach of Haldor Topsoe describe ReShift ™ technology, a new high temperature CO 2 reforming process, where preheated CO 2 is added directly downstream of a main reformer and then equilibrated in an adiabatic reactor. This new technology makes use of the high temperature of the reformer effluent to circumvent carbon formation, while at the same time maintaining an overall minimum steam to hydrocarbon carbon ratio, depending on process specific conditions. An increase in the amount of CO 2 added to the process will result in an increased fraction of CO in the produced synthesis gas. Synthesis gas with H 2 /CO ratios in the range 0.5-3 can be produced. These CO-rich gases are typically utilised in the production of functional chemicals and synthetic fuels.