Towards a sustainable nitrogen fertilizer industry:

Georgy Eliseev , Principal Analyst at Fertecon for IHS Markit, looks at the medium to long term outlook for both ‘green’ and ‘blue’ ammonia production.

Georgy Eliseev , Principal Analyst at Fertecon for IHS Markit, looks at the medium to long term outlook for both ‘green’ and ‘blue’ ammonia production.

The Nigerian National Petroleum Corporation (NNPC) says that it plans to build a $3 billion methanol plant on Brass Island in the Niger Delta to produce up to 10,000 t/d of methanol using from gas supplied by Shell. A final investment decision was made by NNPC, DSV Engineering and the Nigerian Content Development and Monitoring Board, a state agency set up to ensure Nigerian involvement in oil and gas projects. Around 70% of funding for the project will come from international lenders, including the China Export-Import Bank, the African Development Bank and international commercial banks, with the rest funded from an equity issue. BP has signed a 10 year offtake deal for the plant’s output with the Brass Fertilizer & Petrochemical Company, the entity set up to operate the plant. Construction of the plant is expected to be completed by 2025.

Copenhagen Infrastructure Partners (CIP) has unveiled plans to build Europe’s largest power-to-ammonia facility at the Danish port of Esbjerg, based on electricity from offshore wind turbines. The company said the plant will consist of 1GW of electrolysis capacity, capable of supplying sufficient hydrogen to produce 300,000 t/a of ammonia, and that the ammonia will be used as both as agricultural fertiliser and as fuel for the shipping industry. Excess heat generated in the process would be used to provide heating for around one third of local households in communities around the plant, to be sited on the west coast of Denmark. The company has signed a memorandum of understanding for the project with companies from both the agriculture and shipping sectors, including Danish Crown, Arla, DLG, Maersk and DFDS Seaways. CIP anticipates that it would cost approximately $1.2 billion to build the facility. They are currently seeking investors for the project and expect that the investment decision would be reached by 2023. The plant could enter commercial operations in 2026.

The profound demand shock caused by Covid-related lockdowns has had a major impact upon the refining industry. Run rates have been at low levels in North America and Europe, and a new wave of rationalisation is under way, at the same time that capacity continues to grow in Asia. Will this spur diversification into petrochemicals and low carbon options for Atlantic basin refiners?

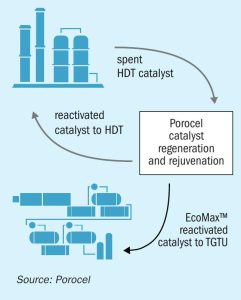

EcoMax™ tail gas catalysts offer a sustainable and cost effective choice for tail gas catalysts. They are made from spent hydroprocessing catalysts, which reduces the environmental and socioeconomic impacts of sourcing fresh cobalt and molybdenum and therefore supports operators’ sustainability goals. B. Visioli of Porocel (a part of Evonik) discusses the benefits of catalyst reuse from hydroprocessing for tail gas treating.

Wet sulphuric acid technology when used as tail gas treatment for a Claus unit, or in place of a Claus unit with amine-based tail gas unit, brings many benefits if there is a market for the sulphuric acid and steam. A new alternative is to have a WSA unit in combination with a Claus unit and to recycle the acid to the Claus unit for higher sulphur recovery efficiency.

Sour gas processing presents a number of unique challenges, especially at high levels of hydrogen sulphide and carbon dioxide content.

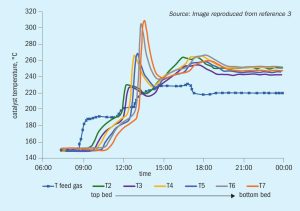

Euro Support’s new generation, titania-based low temperature tail gas catalyst shows a marked robustness to the start-up procedure compared to its common alumina-based counterparts. Dr B. Hereijgers of Euro Support discusses the promising lab results.

Storm Uri which blanketed the southern states of the US with snow, and led to widespread power outages in Texas, has had a major impact upon US Gulf Coast and Southern-Midwest refined products supply. Most Gulf Coast refineries were shut down or forced to operate at reduced rates. IHS Markit estimated that more than 5.2 million bbl/d of Gulf Coast capacity and 730,000 bbl/d in PADD 2 was impacted by the winter weather at its height, and close to 20% of lower 48 US natural gas production was shut-in in the first half of February. A drop in crude oil production of between 2.2 and 4 million bbl/d was estimated.

It can’t have escaped anyone’s notice that the question of the carbon intensity of ammonia and downstream nitrogen compound production has been one of the main industry talking points for the past year. Everyone seems to be talking about ammonia of different colours – green ammonia, blue ammonia, and all shades of turquoise in between. If you are confused, it may not be surprising, as these words have come to cover a wide variety of different methods and technologies for producing ammonia, and their green credentials consequently come in a whole range of different shades.