Sulphur + Sulphuric Acid 2021

A look at papers presented at CRU’s annual Sulphur + Sulphuric Acid conference, which was once again held virtually, in November 2021.

A look at papers presented at CRU’s annual Sulphur + Sulphuric Acid conference, which was once again held virtually, in November 2021.

Developments in sulphuric acid technology and engineering know-how are highlighted by recent project case studies from DuPont Clean Technologies, Metso Outotec and thyssenkrupp Uhde.

Lithium-boron miner ioneer Ltd has awarded DuPont Clean Technologies a contract for the license, engineering, and supply of proprietary equipment for a planned sulphuric acid plant at the company’s Rhyolite Ridge project in Nevada. DuPont will work with engineering partner SNC-Lavalin on the plant design, using MECS® sulphuric acid technology for the 3,500 t/d sulphur-burning unit, as well as controls that limit emissions to among the lowest in the world for this type of facility. DuPont will also supply its latest generation MECSSuper GEAR® ™ catalyst and other critical proprietary equipment. The contract is conditional on a final investment decision by the ioneer board of directors.

INEOS Enterprises has announced the completion of the sale of its Sulphur Chemicals business to International Chemical Investors Group, for an undisclosed sum. INEOS Sulphur Chemicals business is Spain’s largest dedicated manufacturer of sulphuric acid and oleum, serving clients in both agriculture and chemical intermediates via its 400,000 t/a plant in Bilbao. The business will become part of WeylChem’s advanced intermediates and reagents portfolio, which includes an existing sulphuric acid and oleum plant located in Lamotte, northern France. WeylChem is wholly owned by the International Chemical Investors Group (ICIG).

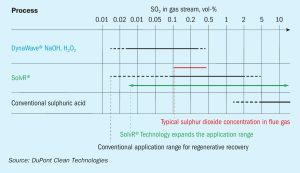

Tightening regulations and growing global competition are increasing the pressure felt by sulphuric acid plant operators to reduce emissions and improve energy output. Conservation of energy is a continuous focus for operators, and environmental communities have grown more vocal in their desire for greater emissions oversight. In this article, DuPont Clean Technologies examines simple, tried, and true tactics, as well as new products and designs that can be incorporated into existing plants to address operating efficiency and emissions and to help to prolong the life of the plant.

Production has begun at Ivanhoe Mines’ Kakula copper mine in the DRC. The company says that total production for this year is expected to be 80-95,000 t/a of copper in concentrate, with a phase two expansion to 400,000 t/a due to be completed by Q2 2022. Ivanhoe is working with China’s Zijin Mining on the development plan for phases 2 and 3 of the mine, as well as a feasibility study for the Kipushi zinc mine further to the east. Both projects lie close to the DRC’s southern border, with Angola and Zambia respectively. Phase 3 of Kamoa will lift capacity to an anticipated 600-800,000 t/a of copper in concentrate, making it the second largest copper mine in the world after Escondida in Chile. Canadian-based Ivanhoe expects to be digging 3.8 million t/a of ore at Kakula with 6% copper content in Phase 1.

Developments in sulphuric acid technology and engineering know-how are highlighted by recent project case studies from DuPont Clean Technologies, Metso Outotec and thyssenkrupp Uhde.

Storm Uri which blanketed the southern states of the US with snow, and led to widespread power outages in Texas, has had a major impact upon US Gulf Coast and Southern-Midwest refined products supply. Most Gulf Coast refineries were shut down or forced to operate at reduced rates. IHS Markit estimated that more than 5.2 million bbl/d of Gulf Coast capacity and 730,000 bbl/d in PADD 2 was impacted by the winter weather at its height, and close to 20% of lower 48 US natural gas production was shut-in in the first half of February. A drop in crude oil production of between 2.2 and 4 million bbl/d was estimated.

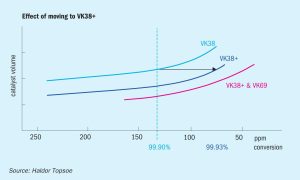

Selecting the right catalysts for the SO2 converter in a sulphuric acid plant has always been about balancing expenses, gains, and compliance. With increasing demands for sustainability and in challenging economic times, operators need to adjust their plants to get even more from less. This has led to market demand for new catalytic solutions that offer better productivity and a lower climate footprint, all at the lowest cost possible. Catalyst design and formulations continue to evolve with Haldor Topsoe, DuPont Clean Technologies and BASF all adding new types of sulphuric acid catalysts to their portfolios.

Norilsk Nickel has finally closed down its nickel smelting operation at Nikel in Russia’s Murmansk region; the company’s oldest still operating production facility. The shutdown is part of the company’s environmental programme, which aims to significantly reduce its environmental impact at all production sites. The Nikel closure will eliminate SO2 emissions in the cross-border area with Norway, which had become a major bone of contention with the Norwegian government. Norilsk aims to reduce SO2 emissions at Kola by 50% by the end of 2020 and 85% by the end of 2021, and is modernising its production in Monchegorsk, including the construction of new state-of-the-art facilities.