Nitrogen and methanol in the Caribbean

Gas availability and pricing continues to affect ammonia and methanol output from Trinidad, while Venezuela struggles with sanctions and political instability.

Gas availability and pricing continues to affect ammonia and methanol output from Trinidad, while Venezuela struggles with sanctions and political instability.

Judging by the pages of the project announcements in our news section, you’d be forgiven for thinking that the ammonia and methanol industries were all running off hydrogen generated from electrolysis, and that we had already entered an era of ‘clean’ chemical generation which did not require fossil fuels as a feedstock. Of course, while companies can naturally be forgiven for wanting to put the best public face on their green credentials, it does obscure the fact that for the moment 99% of syngas generation comes from natural gas, coal, and some coke or naphtha.

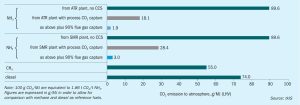

Reducing the carbon footprint in the synthesis of chemicals is a new global challenge as the world works towards providing sustainable products designed to minimise their environmental impacts throughout their whole lifecycle. This article looks at the role of blue technologies as part of a roadmap towards the decarbonisation of fuels and chemicals.

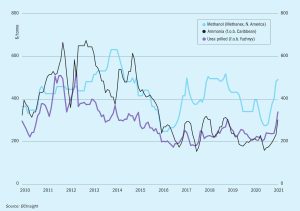

The ammonia industry faced a difficult February, due to extremely cold weather conditions in the northern hemisphere. In the US, production outages resulting from winter storm Uri affected up to 7 million t/a of capacity.

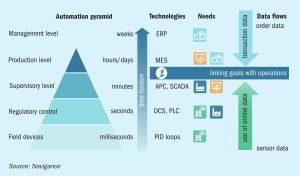

As industry trends add pressure to optimise processes, new digital technologies for roundthe-clock, data-driven decision-making can help plants boost production efficiency without time-consuming manual analysis or large-scale investment. Here, Dr S. Werner of Navigance explores their potential and shares the difference they are already making.

The ammonia industry seems to have quite a buzz about it at the moment. As can be glimpsed in our Nitrogen Industry News section this issue, the number of proposed green ammonia production sites continues to grow, as does interest in ammonia as a hydrogen or energy carrier, while the shipping sector continues to seriously consider ammonia as a green fuel candidate for the longer term. The latter prospect could see current ammonia demand double by 2050, although as our article on sustainable nitrogen production on page 22 notes, whether enough renewable power will exist by then to generate that must be seriously doubted.

The Nigerian National Petroleum Corporation (NNPC) says that it plans to build a $3 billion methanol plant on Brass Island in the Niger Delta to produce up to 10,000 t/d of methanol using from gas supplied by Shell. A final investment decision was made by NNPC, DSV Engineering and the Nigerian Content Development and Monitoring Board, a state agency set up to ensure Nigerian involvement in oil and gas projects. Around 70% of funding for the project will come from international lenders, including the China Export-Import Bank, the African Development Bank and international commercial banks, with the rest funded from an equity issue. BP has signed a 10 year offtake deal for the plant’s output with the Brass Fertilizer & Petrochemical Company, the entity set up to operate the plant. Construction of the plant is expected to be completed by 2025.

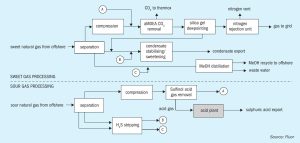

M. Baerends of Fluor reports on the conception, engineering, construction, commissioning and start-up of a new sulphuric acid plant that replaced an existing acid plant at a European sour gas processing terminal. This highly complex gas processing facility handles sour gas from an off-shore field, containing H2 S that must be removed to meet transmission grid specifications. Various issues encountered, their resolution by the joint owner, Fluor and Topsoe team, and plant operating results are discussed.

Johnson Matthey (JM) has secured a multiple licence for China’s Ningxia Baofeng Energy Group’s latest project to develop five of the largest single train methanol plants in the world. Located at Baofeng’s Ordos City complex in Inner Mongolia, the five plants each have a planned capacity 7,200 t/d. Under the agreement Johnson Matthey will be the licensor of all five plants and supplier of associated engineering, technical review, commissioning assistance, and catalyst. The plants will take synthesis gas as a feed and use JM radial steam raising converters in a patented series loop. Within the design, there is potential for 1-2% more feedstock efficiency over the life of the catalyst. Thanks to JM’s methanol loop synthesis technology, the plants will provide enhanced energy savings along with low OPEX, CAPEX and emissions. When complete, the plants will represent JM’s 13th operating license in China for a mega-scale plant (>5,500 t/d) and the fourth JM methanol design licensed by Ningxia Baofeng Energy.

Natural gas pricing remains the dominant component of ammonia production costs. The fall in global oil and gas prices due to the Covid outbreak and the continued growth in the LNG market is continuing to break the hold of oil indexation on gas pricing. Meanwhile, reform of gas markets continues, in places as diverse as Brazil, China and India.