US nitrogen capacity

New carbon capture-based plants could see US nitrogen capacity jump over the next few years, but Trump attacks on IRA tax credits may scupper some ongoing projects.

New carbon capture-based plants could see US nitrogen capacity jump over the next few years, but Trump attacks on IRA tax credits may scupper some ongoing projects.

Maire Group says that its nitrogen fertilizer technology licensor Stamicarbon has been awarded new contracts related to its NX STAMI UreaTM technology in Canada. The first award is a process design package and the licensing of an integrated urea and diesel exhaust fluid (DEF) production plant currently being developed by Genesis Fertilizers, a farmer-owned consortium, at Belle Plaine, Saskatchewan. The plant will have a urea melt capacity of 2,500 t/d, with operations expected to begin by 2029. Also thanks to a carbon capture and sequestration unit, it will be the first proposed low-carbon nitrogen fertilizer plant in Canada. Stamicarbon will apply its proprietary flash urea melt technology to enhance operational efficiency and reliability while minimising process steam consumption. The plant will also include a DEF facility with a production capacity of 1,500 t/d.

CRU recently relaunched its Fertilizer International and BCInsight Platform. This relaunch coincided with the Fertilizer Latino Americano (FLA) conference in Rio de Janeiro, where we issued our inaugural sentiment survey for delegates. This insight presents and analyses the survey results, which point towards an optimistic tone for 2025 markets in Brazil and beyond. Prices are […]

Expensive feedstock, overseas competition and tightening environmental regulations all pose potential threats to Europe’s nitrogen industry.

A complete list of all articles and news items appearing in Nitrogen+Syngas magazine during 2024.

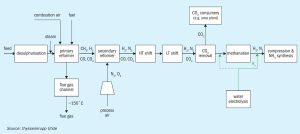

One challenge of a green revamp by stepwise injection of green hydrogen into existing ammonia/urea complexes is to cover the nitrogen demand for the ammonia synthesis while stepwise reducing the front-end load, usually by applying a cost-intensive air separation unit (ASU). thyssenkrupp Uhde GmbH has developed an advantageous concept whereby, instead of an ASU, the nitrogen gap is closed by the introduction of pretreated reformer flue gas back into the ammonia process, with the side effect to also enhance CO2 production.

Join us at the CRU Sulphur + Sulphuric Acid 2024 Conference and Exhibition in Barcelona, 4-6 November, for a global gathering of the sulphur and sulphuric acid community. Meet leading market and technology experts and producers, network, share knowledge, and learn about market trends and the latest developments in operations, process technology and equipment.

Refinery sour water strippers are an often overlooked resource of low GWP ammonia. Martin A. Taylor and Charles L. Kimtantas of Bechtel Energy Technologies and Solutions, Inc. (BETS) show the results of a study on reusing an existing SWS as one of the major systems in a SWSPlus unit for the recovery of ammonia for sale. Relative cost factors will compare a complete SWSPlus unit versus reusing an existing SWS.

Transporting sulphur as a dry bulk solid can lead to it breaking into small particles which create dust. Over the years, various forming processes have been developed to try and minimise dust formation and produce the strongest, most resilient formed sulphur particles.