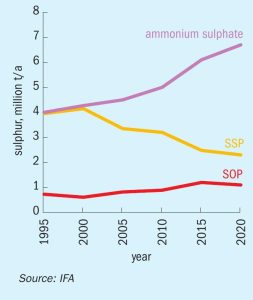

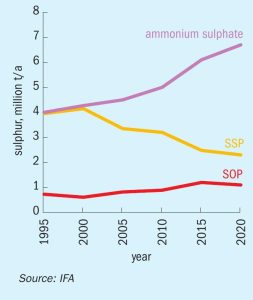

Trends in demand for sulphur fertilizers

Sulphur is becoming an increasingly important crop nutrient, due to a combination of lower airborne sulphur emissions, the increasing prevalence of high analysis fertilizers, and higher cropping intensities.

Sulphur is becoming an increasingly important crop nutrient, due to a combination of lower airborne sulphur emissions, the increasing prevalence of high analysis fertilizers, and higher cropping intensities.

As well as Morocco, Egypt, Algeria and Tunisia all have major phosphate industries, and all of these countries have plans to expand their capability to extract and process phosphates, though Algeria and Tunisia remain hampered by political instability.

The latest developments in the recovery and commercialisation of fluorosilicic acid, rare earth elements (REEs) and uranium co-products associated with phosphoric acid production.

Production has begun at Ivanhoe Mines’ Kakula copper mine in the DRC. The company says that total production for this year is expected to be 80-95,000 t/a of copper in concentrate, with a phase two expansion to 400,000 t/a due to be completed by Q2 2022. Ivanhoe is working with China’s Zijin Mining on the development plan for phases 2 and 3 of the mine, as well as a feasibility study for the Kipushi zinc mine further to the east. Both projects lie close to the DRC’s southern border, with Angola and Zambia respectively. Phase 3 of Kamoa will lift capacity to an anticipated 600-800,000 t/a of copper in concentrate, making it the second largest copper mine in the world after Escondida in Chile. Canadian-based Ivanhoe expects to be digging 3.8 million t/a of ore at Kakula with 6% copper content in Phase 1.

The International Fertilizer Association (IFA) says that Svein Tore Holsether has been elected as its new chair of the Association. IFA said in its press release that the selection of Holsether, the president and CEO of Yara International, is a continuation of the industry’s commitment to sustainability.

The crushing and grinding of mined phosphate rock and potash ore is a vital preparatory step for subsequent beneficiation and chemical processing. Although often overlooked, the efficiency of downstream P & K fertilizer production is heavily reliant on successful particle size reduction upstream.

A holistic understanding of the phosphate milling process is necessary, says Ian Hancock of Bradley Pulverizer. This ensures maximum plant uptime, the highest process efficiencies, and ultimately guarantees profitability.

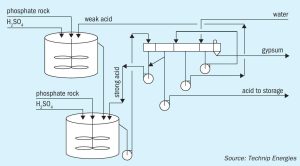

Philippe Malsan of Technip Energies explains how high recovery Diplo phosphoric acid technology can generate phosphogypsum suitable for industrial reuse. Industrial cases studies for Senegal and Austria show how phosphogypsum from this process has been successfully recycled on a large scale for cement, plaster and other end uses.

What lessons can be learnt from the successful commissioning and start-up of major fertilizer industry construction projects? Recent case studies from the nitrogen, phosphate and potash industries provide some interesting answers.

While the covid pandemic has kept refinery run rates down in 2020, new refinery sulphur capacity will nevertheless form the bulk of new additions to sulphur production over the next few years. But delays to projects on both the supply and demand sides could tip a fairly balanced market in either direction.