Phosphates project listing 2024

Fertilizer International presents a global round-up of phosphate rock, phosphoric acid and finished phosphates projects.

Fertilizer International presents a global round-up of phosphate rock, phosphoric acid and finished phosphates projects.

Kevin De Bois of Prayon Technologies describes an innovative process for removing magnesium from phosphate rock. Increasingly, phosphoric acid producers are looking to consume low-grade phosphate rock as a feedstock due to the prohibitive costs of high-grade rock sources. This has potentially negative consequences as the presence of impurities such as magnesium can negatively affect both the phosphoric acid process and the quality of the acid produced.

CRU Events will convene the 2024 Phosphates International Conference & Exhibition in Warsaw at the Hilton Warsaw City Hotel, 26-28 February.

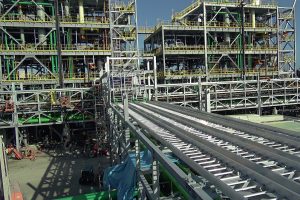

Adani Enterprises says that its new greenfield copper smelter at Mundra in Gujarat, being developed by its subsidiary Kutch Copper Ltd, will begin operations in March 2024. The $1.1 billion project will have an annual production capacity of 1 million t/a of copper once the second phase is complete, but the March 24 start-up will be for the first, 500,000 t/a phase. The plant will also produce 25 t/a of gold, 250 t/a of silver, and 1.5 million t/a of sulphuric acid and 250,000 t/a of phosphoric acid as by-products. India currently imports roughly two million t/a of sulphuric acid since the closure of the Vedanta smelter in Tamil Nadu.

Leading companies such as Ballestra, Buss ChemTech, Elessent Clean Technologies (MECS) and Prayon Technologies are working together to solve the numerous production challenges facing the operators of integrated phosphate fertilizer production plants.

Despite being an age-old industry, the phosphate sector remains vibrant and driven by a passionate commitment to leaving behind a sustainable world for future generations. Tibaut Theys, general manager of Prayon Technologies, explains how the industry, by implementing more efficient production processes and promoting responsible fertilizer usage, is working urgently to reduce CO2 emissions, as well as striving to minimise its environmental footprint.

In this review article, Hatch’s Jayden Ladebruk, Lyndsay Tran, Amelia Parrenin, and Edward DeRose outline the wide range of phosphoric acid production technologies, and discuss how industry challenges are influencing the choice of phosphoric acid process.

The first global review of phosphate rock resources since 2010 has reported that technically recoverable reserves should last for more than 300 years.

Arafura Rare Earths Ltd has awarded Worley subsidiary Chemetics Inc the contract to install Chemetics CORE-SO2™ sulphuric acid technology at its Nolans Project in the Northern Territory of Australia. The scope of the contract is to deliver the detailed engineering and supply of the sulphuric acid plant plus associated oxygen plant on a lump sum basis. The acid plant at Arafura’s Nolans Project will be designed to meet future emission performance and clean energy transition goals, utilising CORE-SO2’s high turndown capability and the potential to idle the plant while keeping the catalyst warm for extended periods of time, allowing the acid plant to operate with 95% reduced SO 2 emissions when compared to traditional double contact double absorption (DCDA) plants. High pressure steam production within the process will allow CO 2 - free electrical power to be generated. By removing the use of a diesel or natural gas start-up burner, further greenhouse gas emissions will be prevented.

Advances in technology, equipment and reagents are enhancing phosphate fertilizer production. Optimisation of standard equipment is also vital for ensuring process efficiency.