Fertilizer Industry News Roundup

CF Industries has signed an agreement with thyssenkrupp to develop a commercial-scale green ammonia project at its Donaldsonville production complex in Louisiana.

CF Industries has signed an agreement with thyssenkrupp to develop a commercial-scale green ammonia project at its Donaldsonville production complex in Louisiana.

Developments in sulphuric acid technology and engineering know-how are highlighted by recent project case studies from DuPont Clean Technologies, Metso Outotec and thyssenkrupp Uhde.

With declining ore grade feed to a metallurgical smelting process comes an increase in impurity load in the gas cleaning/acid process chain. K. Hasselwander, L. Skilling and C. Bartlett of Metso Outotec discuss a range of process solutions and how to maintain high productivity while keeping costs in check.

We report on the latest potash mining and processing technology from Andritz, Ebner, Köppern, K+S and Veolia. Recent case studies for potash projects globally are also provided.

The economic conversion of phosphogypsum waste into a valuable product has been pursued for decades. Results of intensive research by thyssenkrupp Industrial Solutions (tkIS) in this area are presented by Peter Stockhoff, Dirk Koester, Stefan Helmle and Carsten Fabian. The approach developed by tkIS shows great potential as a controlled treatment process for phosphogypsum.

thyssenkrupp Industrial Solutions discusses a revamping concept to reduce CO2 emissions by replacing some of the hydrogen in the front end of the ammonia plant with green hydrogen, KBR and Casale report on revamp options to increase the capacity of vintage ammonia plants in the former Soviet Union, Johnson Matthey presents a novel integrated ammonia flowsheet for the production of ammonia, methanol, urea and UFC and Arvos | Schmidtsche Schack discusses the benefits of a new process gas boiler.

Sulphur reports on this year’s Sour Oil and Gas Advanced Technology (SOGAT) conference, which was run as a virtual event at the end of September 2020.

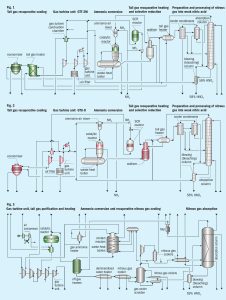

N. Temnaya and S. Suvorkin of NIIK report on the modernisation of monopressure (UKL-7) and dual pressure (AK-72) nitric acid plants in Russia and the CIS.

New technology makes it possible for methanol producers to diversify their product portfolio and participate in the high growth mono ethylene glycol market. A. Shah of Johnson Matthey reports on the development of the new technology and its commercialisation.

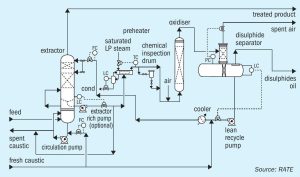

An advanced mecaptan removal process has been developed and implemented by RATE. The RATE-Oximer process is an oxidative air-based regeneration process, designed to remove mercaptans from liquid and vapour phases. M. Rameshini of RATE describes the key features of the process and its applications.