People

H.J. Baker’s chief operating officer (COO) Luis Masroua has become president of the company.

H.J. Baker’s chief operating officer (COO) Luis Masroua has become president of the company.

T he end of August saw a paper published in the Journal of the Royal Geographical Society by Dr Mark Maslin of University College London. Widely reported, it looked at the prospects for sulphur production in an era of declining fossil fuel use, concluding that there could be “a shortfall in the annual supply of sulphuric acid of between 100 and 320 million tonnes by 2040, depending on how quickly decarbonisation occurs”. It added that “unless action is taken to reduce the need for sulphuric acid, a massive increase in environmentally damaging mining will be required to fulfil this resource demand.”

The purpose of this article is to emphasise the lessons learned by ADNOC Sour Gas in the material upgrading of the Shah sulphur granulation plant due to severe corrosion of the aluminium components. The sulphur granulation plant was commissioned in 2015 and consists of a total of 12 granulating systems used for solidifying and granulating the liquid sulphur. The study focused on the corroded areas, namely the GX plenum chambers, the lower section of the granulator exhaust stack, the scrubber inlet and the discharge ducting.

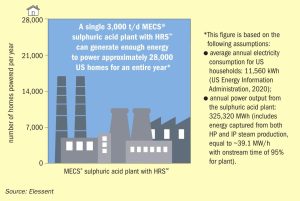

By recovering waste heat as process steam or electrical energy, technologies are available that can help sulphuric acid plants meet their energy goals. Colin Shore of Elessent Clean Technologies discusses how MECS® HRS™ technology can offer a sustainable solution to enhance sulphuric acid plant performance, while lowering its carbon emissions.

In a major blow to the British fertilizer industry, CF Fertilisers UK announced the closure of its Ince production site in north-west England in June (see p8). Ince is the UK’s largest compound fertilizer producer, operating three NPK+S units. It also manufactures large volumes of ammonium nitrate (AN) for Britain’s farmers. At the heart of the Cheshire complex is Ince’s long-standing ammonia plant. Unfortunately, high natural gas costs have kept this shuttered since September last year.

New research findings strongly suggest that iodine behaves as a plant nutrient. SQM International has been quick to follow up on this discovery by launching a new speciality iodine fertilizer for fertigated crops.

It is generally necessary to solidify sulphur into a robust form suitable for handling and long-distance transport. Granulation, pastillation and prilling are some of the technologies used to produce solid sulphur from molten material. Similar technologies are also used to manufacture sulphur fertilizers.

CF Fertilisers UK is to permanently close its fertilizer production site at Ince in north west England with the potential loss of 238 jobs.

In increasingly volatile times for commodity markets, companies up and down the fertilizer supply chain are being left financially exposed to price fluctuations. Alison Coughlin and Tom Crane of CME Group explain how derivatives allow fertilizer market participants to protect themselves from the risk of adverse price movements.

The overuse of limited natural resources and excessive contributions to climate change are just two of the criticisms currently levelled at global agriculture. Plant scientist David Marks is addressing these criticisms head-on through the company he founded, Levity Crop Science. He believes that, with better access to the right products, farmers can bring agriculture back into balance.