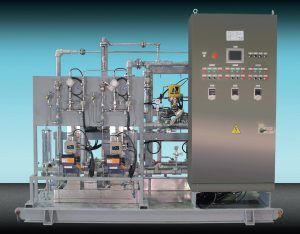

New self-cleaning sulphur strainer

For the protection of nozzles in sulphur forming plants it is important to prevent larger particles from entering the forming machinery and possibly blocking the nozzles. In normal operation, pipeline strainers are used. Sulphurnet has designed a new system which is suitable for continuous or batch operations and has lower maintenance costs. J. Hermans of Sulphurnet introduces the self-cleaning sulphur strainer.