Fertilizer Industry News Roundup

Ammonia production at Billingham in Teesside looks set to end, bringing to a close a history of production that dates back almost a century.

Ammonia production at Billingham in Teesside looks set to end, bringing to a close a history of production that dates back almost a century.

The quality of finished fertilizers can be maintained during transport, handling and storage by protecting the surfaces of granules and prills with coating agents. Valuably, fertilizer coatings can also be used to control the release of nutrients in the field.

Crop residues are the plant materials that are left in the field after the harvested portion is removed. Many growers are increasingly valuing these materials due to their nutrient content and soil health benefits. Dr Karl Wyant, Nutrien’s Director of Agronomy, highlights the value of crop residues and discusses how to manage these more effectively without interfering with on-farm activities. Ag retailers, in particular, are well-placed to advise growers on how to unlock value from their residues.

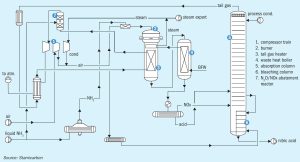

Hydrocarbon-based production of ammonia carries an unavoidable carbon footprint. But one of the best methods for mitigating that footprint is already here: ultra-low carbon-intensity ammonia production, also known as “blue” ammonia. With blue ammonia production, a typical ammonia plant can sequester or repurpose game-changing volumes of carbon dioxide that would otherwise end up in the atmosphere. To help foster an optimal understanding of the benefits, Ameet Kakoti and Per Juul Dahl of Topsoe A/S provide an overview of the technologies that can help any ammonia operation achieve and maintain sustainable operations – sooner rather than later.

Paz Muñoz and Carmen Perez of Stamicarbon discuss the strategic selection of future-proof technology for nitric acid plants. To produce nitric acid in a feasible and sustainable way, manufacturers must carefully choose the right technology and consider the capex and opex involved in the production process to ensure long-term profitability.

Horisont Energi has the aspiration to develop the most carbon and energy efficient blue ammonia plant in the world, an environmentally friendly plant with a focus on sustainable solutions. This article describes the main features of the Barents Blue Ammonia project, such as 99% carbon capture rate target, a high degree of modularisation, winterisation, infrastructure for ammonia and CO2 management and the provision for future expansion.

Although the nitric acid industry has an extensive history dating back centuries, nitric acid production continues to be a dynamic process with bespoke system solutions necessary per plant rather than a one size fits all. Kate Cardonne of Johnson Matthey discusses strategies to balance the cost and performance in nitric acid production.

Linde has developed a new adsorptive carbon dioxide removal process, called HISORP® CC, including but not limited to blue ammonia production. Based on a combination of mature technologies the process overcomes the drawbacks of traditional CO2 removal techniques and provides a carbon capture rate of greater than 99%. Thomas Ried discusses the pros and cons of different process configurations for CO2 removal and the benefits of the new technology.

There is growing acceptance and integration of biostimulants into the wider fertilizer and agricultural markets. This is illustrated by rocketing sales, the spate of new product launches, and merger and acquisition activity.

Technological innovation is vital to solving the global food challenge and delivering the transition to a low-carbon economy. Pejman Djavdan, Stamicarbon’s CEO, sets out his vision for a future-proof fertilizer industry – one that will enable the sustainable intensification of agriculture while also protecting the environment.