Nitrogen Industry News Roundup

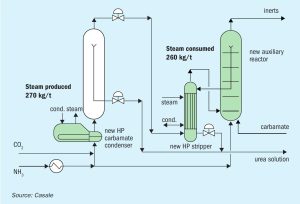

Maire Tecnimont’s innovation and licensing company Stamicarbon has been selected as the licensor for a urea project in sub-Saharan Africa, its first license in the region. Stamicarbon will deliver the process design package for the front-end engineering and design for a 4,000 t/d urea melt and granulation plant. The urea melt plant with a pool reactor will use Stamicarbon’s MP Flash design, a melt concept with improved energy efficiency, entailing a significant reduction of steam consumption. The minimal equipment items result in a significant reduction of the footprint and the overall capital cost of the plant. Less equipment also allows for a reduction in maintenance costs and OPEX savings.