Brazil’s fertilizer market

Debora Simoes, Bruno Fardim , and Cleber Vieira of Agroconsult report on what’s driving the Brazilian fertilizer market currently and look at prospects for the coming year.

Debora Simoes, Bruno Fardim , and Cleber Vieira of Agroconsult report on what’s driving the Brazilian fertilizer market currently and look at prospects for the coming year.

Mexico supplies more than half of the international avocado market. This oil-rich, nutritious fruit is also widely grown in Colombia, the Dominican Republic and Peru. We look at the nutrient needs of this regionally-important cash crop.

Improvements to equipment and materials are driving greater operational performance and higher efficiencies at urea plants. Recent advances are reviewed.

Correct fertilizer usage at each crop stage can helps avocado growers improve their yield, quality and profitability. ICL’s Mateo Martinez and Alveiro Salamanca-Jimenez explain how growers can supply crop nutrients to avocado trees, efficiently and effectively, using economically- and environmentally-sustainable principles.

Sulphur is becoming an increasingly vital crop nutrient – due to a combination of lower sulphur deposition from the atmosphere, the increasing prevalence of high-analysis fertilizers and higher cropping intensity.

Efficient size preparation and ore transport are key prerequisites for successful potash and phosphate production. We highlight the range of equipment options.

The ability to incorporate elemental sulphur within urea granules to create a fertilizer carrier has excellent potential as an answer to global soil sulphur deficiency. This technology is already available for commercial implementation and offers many benefits, as Bernd Peuckmann and Harald Franzrahe of thyssenkrupp Fertilizer Technology explain.

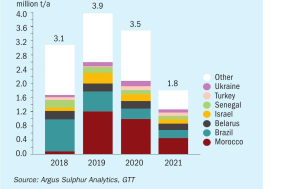

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

The fourth SulGas Conference organised by Three Ten Initiative Technologies took place 1-4 February as a virtual event. Selected highlights from some of the presentations from SulGas 2022 are given below.

Russia’s invasion of Ukraine, the consequent sanctions imposed by European and North American countries, and fears over further sanctions and a widening of the conflict have had sent a systemic shock through the world trading system. Stock markets dropped sharply, and the Russian rouble lost 30% of its value. The most immediate short and medium term impact is likely to come from Russian banks being cut off from the SWIFT international payment system, making exports of commodities more difficult, although no direct restrictions or embargos have been imposed on Russian products as of time of writing.