Sulphuric acid projects and technology

Developments in sulphuric acid technology and engineering know-how are highlighted by recent project case studies from DuPont Clean Technologies, Metso Outotec and thyssenkrupp Uhde.

Developments in sulphuric acid technology and engineering know-how are highlighted by recent project case studies from DuPont Clean Technologies, Metso Outotec and thyssenkrupp Uhde.

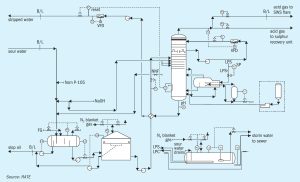

The Valkyrie™ process was first introduced as a reborn version of redox technology for treating H2 S in natural gas processing.In this article Streamline Innovations Inc. highlights some of the new developments and successful applications of the Valkyrie process and its redox technology, in both gas and water streams.

M. Rameshni and S. Santo of RATE discuss different sour water stripping gas processing options, depending on contaminants in the sour water streams and site-specific requirements.

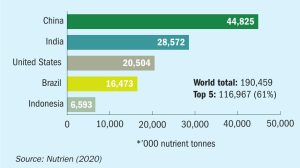

We report on the state of US fertilizer production and supply. The US industry – the second-largest finished phosphates producer and third-largest urea producer globally – has grown and developed alongside North America’s mature and sophisticated domestic farming sector.

An update on the latest in fertilizer ship loading, handling, bagging and blending, including new contracts, company news and advances in technology.

Boron is a key micronutrient required by fruit and vegetables and crops such as corn, cotton, rice, soybean and sugar cane. The agricultural importance of boron and the wide range of products on the market are described.

BHP has finally given the go ahead for stage one of its Jansen potash mine project in Saskatchewan, Canada.

Venkat Pattabathula, a member of the AIChE Ammonia Safety Committee, reports on the American Institute of Chemical Engineers’ Safety in Ammonia Plants and Related Facilities Symposium, held virtually on 30 August to 2 September 2021.

The fact that biuret is toxic to plants has been known for a long time – since the middle of the last century. Very sensitive (pineapple, citrus), moderately sensitive (cereals, legumes) and resistant (conifers) plant species were identified. The maximum concentration of biuret in urea for each species has been established for soil application and foliar application. Most field crops easily tolerate foliar fertilization with urea, which contains 1 wt-% biuret. Potatoes and tomatoes are more sensitive – for foliar feeding of these crops, it is advisable to use urea with an admixture of biuret of no more than 0.5 wt-%. Citrus fruits and pineapples are so sensitive that biuret in urea for foliar feeding should be no more than 0.35 wt-%.

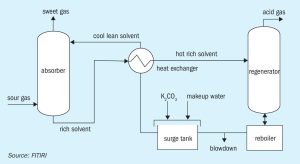

Arun Murugan and Mike Antony of FITIRI and Venkat Pattabathula of SVP Chemical Plant Services discuss the COORS Analytics system for more accurate prediction of the performance of a CO 2 removal system.