State of the art potash production

We report on the latest potash mining and processing technology from Andritz, Ebner, Köppern, K+S and Veolia. Recent case studies for potash projects globally are also provided.

We report on the latest potash mining and processing technology from Andritz, Ebner, Köppern, K+S and Veolia. Recent case studies for potash projects globally are also provided.

The Belarusian Potash Company (BPC) has agreed new annual potash supply contracts with India and China.

The Mosaic Company received the 2020 Robert W Campbell Award from the US National Safety Council in February. This prestigious award celebrates the company’s excellence in environment, health and safety (EHS) and its achievements over a decade of continuous improvement. During this period Mosaic’s commitment to EHS has delivered an 80 percent improvement in its recordable injury rate and led to the creation of its Risk Reduction Program.

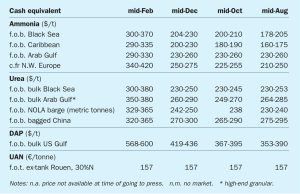

Market Insight courtesy of Argus Media

An industry-wide push for greater environmentally accountability is driving the need for improved fertilizer cooling methods. Not only is indirect cooling technology more environmentally-friendly, says Igor Makarenko of Solex Thermal Science, it also provides fertilizer manufacturers with a better product.

The economic conversion of phosphogypsum waste into a valuable product has been pursued for decades. Results of intensive research by thyssenkrupp Industrial Solutions (tkIS) in this area are presented by Peter Stockhoff, Dirk Koester, Stefan Helmle and Carsten Fabian. The approach developed by tkIS shows great potential as a controlled treatment process for phosphogypsum.

We highlight recent advances in ammonia and dust scrubbing systems for urea plants from Stamicarbon, thyssenkrupp Industrial Solutions and Toyo Engineering Corporation.

Market Insight courtesy of Argus Media

Shutdowns in technical ammonia capacity due to the pandemic have contributed to make 2020 a turbulent year for ammonia markets, but plant shutdowns, strong fertilizer demand and a shortage of new merchant ammonia capacity are contributing to finally removing the burden of overcapacity.

Ammonia synthesis catalysts have long lives and catalyst replacement is an infrequent activity. Many people will go through their careers in the ammonia industry without ever having to replace a synthesis catalyst and the infrequent nature of catalyst replacement means that many plants may not have direct experience of this activity. Ammonia synthesis catalyst can present a range of hazards throughout the replacement process, from transport through loading, reduction, start-up, shutdown and discharge, but the good practice illustrated in this article, and collaboration between catalyst suppliers and end users can ensure safe and successful catalyst changeouts.