CRU Nitrogen + Syngas 2021

Because of the ongoing pandemic, this year’s CRU Nitrogen + Syngas conference was held as a ‘virtual’ event, in early March 2021.

Because of the ongoing pandemic, this year’s CRU Nitrogen + Syngas conference was held as a ‘virtual’ event, in early March 2021.

Georgy Eliseev , Principal Analyst at Fertecon for IHS Markit, looks at the medium to long term outlook for both ‘green’ and ‘blue’ ammonia production.

From new materials of construction and improved equipment designs to the latest digital tools, Casale, thyssenkrupp Industrial Solutions, Saipem, TOYO and Stamicarbon report on some of their latest achievements.

This year’s SulGas conference, covering sulphur recovery and gas treating with a special focus on India and southeast Asia, was run as a virtual event from February 1st to 3rd 2021.

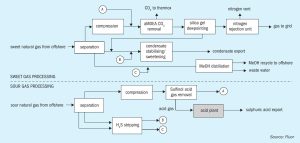

M. Baerends of Fluor reports on the conception, engineering, construction, commissioning and start-up of a new sulphuric acid plant that replaced an existing acid plant at a European sour gas processing terminal. This highly complex gas processing facility handles sour gas from an off-shore field, containing H2 S that must be removed to meet transmission grid specifications. Various issues encountered, their resolution by the joint owner, Fluor and Topsoe team, and plant operating results are discussed.

Wet sulphuric acid technology when used as tail gas treatment for a Claus unit, or in place of a Claus unit with amine-based tail gas unit, brings many benefits if there is a market for the sulphuric acid and steam. A new alternative is to have a WSA unit in combination with a Claus unit and to recycle the acid to the Claus unit for higher sulphur recovery efficiency.

Sour gas processing presents a number of unique challenges, especially at high levels of hydrogen sulphide and carbon dioxide content.

Demand for nickel sulphate is expected to rise rapidly this decade to feed increased battery production for electric vehicles. At the same time, diminishing sources of high grade nickel ores are leading to a renewed focus on high pressure acid leaching (HPAL) of laterite ores, with a significant impact on sulphur and sulphuric acid demand.

As the Covid-19 pandemic continues, we look ahead at fertilizer industry prospects for the next 12 months, including the key economic and agricultural drivers likely to shape the market during 2021.

The United States has imposed duties on Russian and Moroccan phosphate imports.