Phosphate process analysers

Sophisticated control of phosphates production is now possible thanks to the availability of real-time process analysers. We assess the range of technologies currently on the market and their key advantages.

Sophisticated control of phosphates production is now possible thanks to the availability of real-time process analysers. We assess the range of technologies currently on the market and their key advantages.

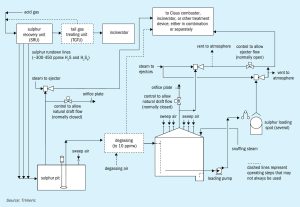

Undegassed molten sulphur can contain several hundred ppmw H2 S. If the headspace in the storage tank is stagnant, the H2 S can accumulate in the vapour space above undegassed liquid sulphur to dangerous levels. Sweeping and blanketing systems are commonly applied to manage the explosion risk in the headspace of molten sulphur storage tanks. D. J. Sachde , C. M. Beitler , K. E. McIntush , and K. S. Fisher of Trimeric Corporation review these approaches, outlining the benefits and limitations, design considerations, and industry experience/guidance for each approach. Calculation methods for natural draft flow of sweep air are also presented.

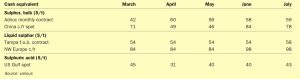

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

In a few short years Abu Dhabi has grown to become the world’s largest sulphur producer and exporter, and new sour gas projects will lead to additional sulphur recovery capacity, provided they can overcome economic challenges.

Reg Adams of pigments and titanium dioxide consultancy Artikol reviews the demand for sulphuric acid in the manufacture of TiO2 , and the prospects for consumption over the next few years.

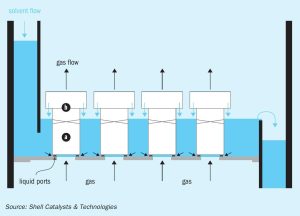

G. Bowerbank and W. Blas of Shell Catalysts & Technologies discuss low cost strategies to maximise value at existing gas processing facilities. Changing solvents, introducing advanced column internals or a combination of both are relatively simple and cost-effective options for boosting production or revenue with minimal investment.

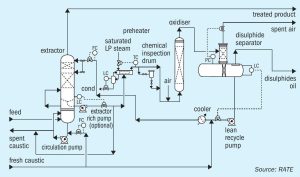

An advanced mecaptan removal process has been developed and implemented by RATE. The RATE-Oximer process is an oxidative air-based regeneration process, designed to remove mercaptans from liquid and vapour phases. M. Rameshini of RATE describes the key features of the process and its applications.

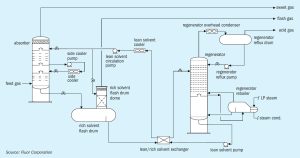

Fluor’s case study of recently constructed ultra-sour gas treating facilities provides new information about the operation of DGA-based AGRUs. B. Lynch and C. Graham of Fluor Corporation discuss how using this knowledge and leveraging the recent improvements to process simulators in the gas sweetening space, Fluor has developed an efficient, flexible, and cost effective solution in the two-stage absorption process to maximise mercaptan removal from ultra-sour gases with minimal equipment.

Spanish fertilizer producer Fertiberia is teaming up with energy firm Iberdrola to build Europe’s largest plant for generating green hydrogen for industrial use – in this case ammonia production. The 100MW solar plant and accompanying 20 MWh lithium-ion battery system and 20MW electrolytic hydrogen production system will be built at a cost of $174 million, and electrolyse water to produce 720 t/a of hydrogen. When fed into Fertiberia’s existing ammonia plant at Puertollano, 250km south of Madrid, the hydrogen will allow a 10% reduction in natural gas use by the plant, saving the company 39,000 t/a in annual CO 2 emissions. Start-up is planned for 2021. Fertiberia will also use electrolysis-generated oxygen as a raw material for nitric acid, which is used to produce ammonium nitrate at the site.

TechnipFMC’s EARTH ® technology, with its structured catalyst jointly developed by TechnipFMC and Clariant, has been proven to be a cost effective way to drastically improve productivity and energy efficiency of the steam reforming process, while reducing the CO 2 footprint per unit hydrogen and syngas product. The technology can be applied in projects to increase the capacity of ammonia and methanol plants and allows significant reduction of greenhouse gas emissions. S. Walspurger of Technip Benelux B.V. and S. Gebert of Clariant GmbH report on the EARTH ® technology and its applications.