CRU Phosphates 2024

More than 370 delegates from over 150 companies and 40 countries gathered at the Hilton Warsaw City Hotel, Warsaw, Poland, 26-28 February, for CRU’s Phosphates 2024 conference.

More than 370 delegates from over 150 companies and 40 countries gathered at the Hilton Warsaw City Hotel, Warsaw, Poland, 26-28 February, for CRU’s Phosphates 2024 conference.

OCP Group and Fortescue subsidiary Fortescue Energy have announced a 50:50 joint venture (JV) to supply green hydrogen, ammonia and fertilizers to Morocco, Europe and international markets.

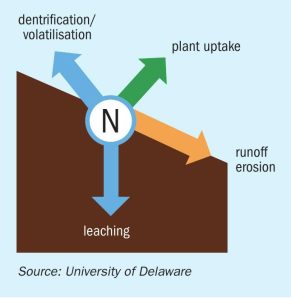

Addressing the ‘leaky’ nature of nitrogen fertilizers is a longstanding priority for growers, fertilizer producers and retailers alike. Dr Karl Wyant, Nutrien’s Director of Agronomy, examines the valuable role enhanced efficiency fertilizers (EEFs) can play in improving nitrogen use efficiency.

Over the last six months, climate and geopolitical events have disrupted seaborne trade. A record drought in Panama and the unprecedented intensity of attacks on commercial ships by the Houthi rebels in the Red Sea are straining the freight market. Almost 150 ships have been targeted along the latter trade route since the first attack was registered to a non-commercial ship last year.

Digitalisation is making a strong impact in the process industry and is providing an opportunity to have a positive impact on the production KPIs. Metso’s Metals & Chemical Processing Business reviews the impact of digitalisation in the sulphuric acid industry today and discusses the concept of a future pit-to-port system within a digital eco-structure.

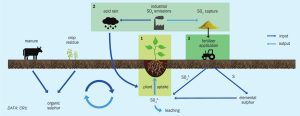

Sulphur plays an important role in crop nutrition. Indeed, sulphur is increasingly being recognised as the fourth major crop nutrient alongside N, P and K. However, a combination of intensive agricultural practices, increasing application of high-analysis fertilizers and tighter air quality regulations has led to increasing sulphur deficiency in soils. In this insight article, CRU’s Peter Harrisson looks at what’s driving sulphur deficiency and whether there’s a gap in the market for sulphur fertilizers.

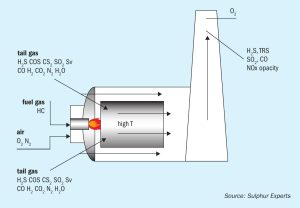

Sulphur Experts outline the steps required to determine optimised SRU incinerator operating conditions. Although a proper determination of the ideal SRU incinerator operating conditions for any given facility is complicated by a combination of inconsistent permitting standards and poor understanding of the role of the SRU incinerator, the payoff for incinerator optimisation is a significant decrease in natural gas usage with corresponding savings in operating costs, a decrease in CO2 emissions, and a simultaneous reduction in NOx and SO3 emissions.

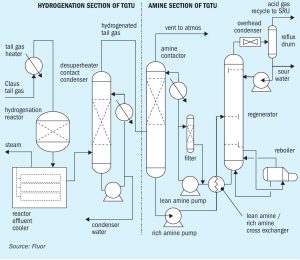

As environmental SO2 emission regulations become more stringent, tail gas treating options become limited. To potentially achieve lower opex and improved plot plan, utilising a biological desulphurisation process as an alternative to a conventional amine-based TGT unit is becoming of increased interest in the oil and gas industry. At the same time, demands for increased SRU capacity and reliability favour the use of medium and high-level oxygen enrichment.

Qatar construction services company UCC Holding has signed a memorandum of understanding with the Kazakh Ministry of Energy for a gas treatment plant at the Kashagan field with a capacity of 6 billion cubic meters as part of the Phase 2B expansion. The memorandum was signed by Minister of Energy Almassadam Satkaliyev and Mohamed Moutaz Al Khayyat, chairman of UCC Holding.

Cobalt-molybdenum (CoMo) catalysts are integral components of tail gas units (TGUs), playing a vital role in reducing harmful sulphur dioxide (SO2 ) emissions arising from Claus sulphur recovery units. Effective activation of these catalysts is essential for their optimal performance. The consequence of sulphiding at low temperatures and atmospheric pressure in low temperature TGUs is to compromise effectiveness of catalyst activation. In the final part of this two-part article, Michael Huffmaster , Consultant, presents case study results using a discrete reactor model incorporating heat, mass transfer, and activation reaction kinetics to assess the impacts of these variables on in-bed temperature profile and activation effectiveness. Tailoring gas rate, composition, and temperature progression can achieve in-bed exotherms which improve CoMo catalyst activation effectiveness for low temperature tail gas units.