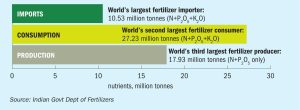

Paradeep Phosphates Ltd (PPL) says that it has signed a memorandum of understanding with the government of Odisha state to invest $440 million over five years to increase its phosphate fertilizer production and export capacity, including port/ jetty and infrastructure development. PPL currently has capacity to produce 400,000 t/a of urea and 2.6 million t/a of finished phosphates, via DAP and NPK plants in Paradeep, Odisha, and Zuarinagar, Goa. Details of the expansion were not announced, but the company previously said in December 2024 that it had agreed to expand phosphoric acid capacity from 500,000 t/a to 700,000 t/a to increase backwards integration of production and reduce dependence on imports.