Constraints on renewable production

With low carbon ammonia and methanol being considered not just for their chemical and fertilizer uses, but as fuels, can we make enough of them to fill our energy needs?

With low carbon ammonia and methanol being considered not just for their chemical and fertilizer uses, but as fuels, can we make enough of them to fill our energy needs?

Proman has signed a memorandum of understanding (MoU) with Mitsubishi Corp to collaborate on the development of a blue ammonia plant at Lake Charles, Louisiana. This new facility will aim to produce around 1.2 million t/a of low carbon ammonia, making it one of the largest of its kind in the world. The plant will incorporate carbon capture and sequestration technology. Proman says that this development aligns with the company’s commitment to sustainability and reducing greenhouse gas emissions. The proposed ammonia plant will be located at Proman’s existing site in Lake Charles, adjacent to its gas-to-methanol plant, which is also currently being developed.

First Quantum Minerals Ltd. has contracted with MECS, Inc. (MECS), a subsidiary of Elessent Clean Technologies, for the Kansanshi smelter expansion at the Kansanshi mine at Solwezi. MECS’ scope of work will include a redesign of the existing sulphur-burning sulphuric acid plant into a copper smelter off-gas recovery sulphuric acid plant. This transition to a copper smelter off-gas recovery acid plant will enable First Quantum to reduce emissions from the existing copper smelter, increase production at the mine, and supply more copper to the global market, which will enable the adoption of greener technologies. MECS’ design for First Quantum incorporates proprietary technologies such as MECS® catalyst for low emissions and high conversion, Brink® mist eliminators, ZeCor® alloy towers and pump tank and UniFlo® acid distributor technology for operational reliability and efficiency.

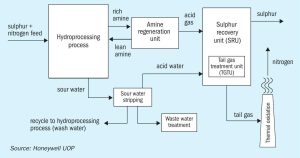

Honeywell UOP’s nViro Hydro process provides an alternative solution to conventional hydroprocessing waste treatment utilising a sulphur recovery unit and tail gas treating unit. Janet Ruettiger of Honeywell UOP discusses the benefits of nViro Hydro which include improved operational efficiency, creating a new revenue stream and reduced capital outlays, operating expenses and water use.

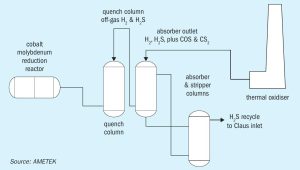

As plants move towards full unit control, Jochen Geiger of Ametek Process Instruments provides an overview of how the latest sulphur plant analysers are providing greater insight into sulphur plant operations.

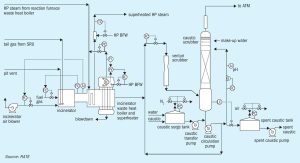

M. Rameshni and S. Santo of Rameshni & Associates Technology & Engineering (RATE USA) discuss some of the many solutions available to revamp sulphur plants to meet stricter environmental regulations with regard to SO2 and CO2 emissions. RATE technologies for the ultimate goal of achieving near zero SO2 emissions and World Bank requirements are also illustrated.

In spite of changing patterns of demand, deglobalisation and environmental concerns, phosphate mining and acid-based processing are likely to be the mainstay of the industry for years to come.

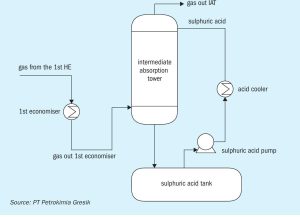

Anggi Arifin Nasution and Aldifi Putro of PT Petrokimia Gresik detail an inventive redesign of their economiser, a critical component in sulphuric acid production, focusing on energy efficiency, decarbonisation, process optimisation, and equipment durability.

Low carbon production is attracting considerable attention to using syngas derivatives as fuels, but there are considerable logistical and commercial barriers to overcome.

Market Insight courtesy of Argus Media