Methanol synthesis using renewable energy

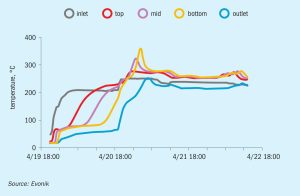

Toyo Engineering Corporation (TOYO), a global leading engineering contractor, has developed g-Methanol® technology. Methanol, traditionally produced from fossil resources, is now gaining attention for synthesis using carbon dioxide and hydrogen from renewable sources. This article explores methanol synthesis technology and the challenges in utilising renewable energy sources.