Unlock the true potential of your SRU

Fluor explores the versatile potential of oxygen enrichment for various revamp and debottlenecking opportunities.

Fluor explores the versatile potential of oxygen enrichment for various revamp and debottlenecking opportunities.

OCP can now produce more than five million tonnes of triple superphosphate (TSP) annually.

Casale’s integrated revamp solutions for ammonia and urea plants are designed to unlock latent potential and boost operational performance.

Revamping existing urea plants can deliver significant improvements – including higher capacity, lower costs and reduced emissions.

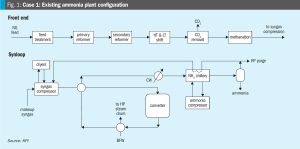

VK Arora of KPI examines the technical and operational challenges of decarbonising legacy and new ammonia plants, drawing on a European case study of full-scale conversion supported by robust process and integration design. It also presents three US case studies exploring partial strategies, such as green hydrogen blending and oxygen enrichment, to reduce CO2 emissions and improve throughput. Together, these examples highlight a phased, cost-effective approach to decarbonisation, with blue hydrogen serving as a near-term transitional feedstock.

Casale is specialised in revamping natural gas-based methanol plants. Decarbonisation of methanol plants is a goal for many producers achievable with a proper revamping strategy. Pietro Moreo of Casale discusses how Casale’s innovative technologies and extensive experience ensure reliable efficient capacity and performance enhancements together with CO2 emissions reduction tailored to meet revamping project targets.

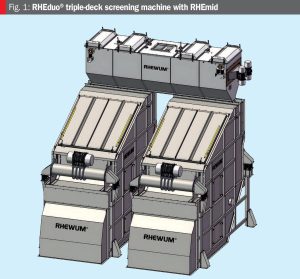

De-bottlenecking is a profitable path for potash producers, as RHEWUM's Tountzer Ramadan and Alexander Krasovsky explain.

Revamps are performed to deliver production improvements at existing urea plants.

Syngas generation units (SGU) represent a large portion of the capital and operational expenditure of ammonia plants and are critical from a mechanical reliability standpoint. Related capex/opex optimisation and mitigation of possible operational problems are key targets for ammonia plant owners. Giovanni Manenti introduces NITROQUENCH® technology which focuses on these key targets for ammonia SGU.

Revamping aging urea plants with the latest urea technology brings many benefits. Not only can greenhouse gas emissions be reduced, but the overall performance and sustainability of these facilities can also be optimised. Hiroo Kunii of Toyo Engineering Corporation discusses TOYO’s approach to urea plant revamping.