Sulphur dust suppression

Sulphur dust is one of the greatest hazards when producing and handling solid sulphur, and methods for its suppression are vitally important to prevent fire and explosion.

Sulphur dust is one of the greatest hazards when producing and handling solid sulphur, and methods for its suppression are vitally important to prevent fire and explosion.

An overview of the very latest in fertilizer handling and blending, including new contracts, company news and advances in technology.

A reader wrote to me recently asking if I had considered the impact of general artificially intelligent systems like ChatGPT on the publishing industry. As a matter of fact I had, but only, somewhat narrowly and selfishly, on how it might impact my own job in the future. But the dramatic shift in AI capabilities that we have seen in the past couple of years is certainly food for thought, and I’ve seen no end of articles predicting the death of the creative industries.

Mining major Anglo American is to invest up to $4 billion to complete its Wood-smith mine project in the UK.

Storing urea under hot and humid ambient conditions can be a chall enge. Several quality parameters of the urea product itself like moisture, temperature and particle size distribution are critical. Fluctuations of these parameters over time are also important and can lead to caking issues and complaints by clients. Off-spec product means big losses in revenue and results in a troublesome stream that has to be handled separately. Learning from each other’s experiences is vital to minimise and avoid these problems. n

CRU’s Nitrogen + Syngas conference convened at the Hyatt Regency Barcelona Tower in Barcelona, from March 5th-8th.

A review of the current slate of plans for green and blue ammonia production.

With Europe facing a long-term shortage of natural gas, and Russia looking east for new customers, how will changing global gas markets affect production of key syngas-based chemicals?

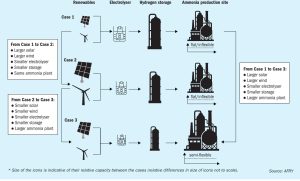

Due to the inherent nature of the renewable power, sizing eSyngas plants powered with renewable energy brings complexity normally not faced by natural gas-based facilities. In this article, Dr Raimon Marin and Dr Solomos Georgiou of AFRY discuss the application of AFRY’s state-of-the-art modelling tool to optimise the size and production of a green hydrogen system and a green ammonia plant based on given renewable power profiles and their associated variability (e.g., hourly, daily, seasonally, and annually).

Sulphur is a relatively safe and inert solid. However, it has a number of unique physical and chemical properties which can give rise to hazards, particularly during transport and handling.