Press Release: Axens Completes Expansion of ACAL site to Produce Hydrogenation Tail Gas Treatment Catalysts in Saudi Arabia

Axens Catalyst Arabia Ltd to manufacture Tail Gas Treatment Catalyst on newly expanded site

Axens Catalyst Arabia Ltd to manufacture Tail Gas Treatment Catalyst on newly expanded site

Kuwait’s state owned Kuwait Oil Company (KOC) has issued a tender for companies to bid on construction of the second phase of its gas sweetening facility at booster station BS 171 in West Kuwait. Thirty-two companies have been pre-qualified to bid for the $390 million engineering procurement and construction (EPC) contract for the project. Phase II will involve the construction of two processing trains, each with a capacity to produce 60 million scf/d of sales gas from sour gas with an H2S content of 4%. Sulphur recovery from the project will come from two separate 100 t/d trains with a total capacity of 65,000 t/a of molten sulphur.

Spetco’s contract with the Kuwait Oil Company (KOC) to install depletion compression systems and sulphur recovery units (SRUs) is said to be awaiting final approval. The $460 million project will upgrade two key facilities in North Kuwait, and Spetco says that it expects project execution will start quickly after final approval. The project involves installing new units at the Early Production Facility 50 (EPF-50) and Jurassic Production Facility 3 (JPF-3) using uses a build-own-operate-transfer (BOOT) contract model. The contract was originally tendered in 2023, but scope changes meant that the deadline has been extended several times.

Maire Group says that its NextChem (Sustainable Technology Solutions) subsidiary has been awarded a three-year contract by Saudi Aramco Total Refining and Petrochemical (SATORP) – a joint venture between Saudi Aramco and TotalEnergies – to provide engineering and technology services related to the sulphur recovery complex of SATORP’s refinery in Jubail, Saudi Arabia. NextChem will provide process and engineering advisory services to enhance performance, support operational troubleshooting, and improve energy efficiency and the carbon footprint of the three units (sulphur recovery unit, amine regeneration unit and sour water stripper) which comprise the sulphur recovery complex. The services will also include recommendations for capital investment opportunities, design enhancements, and technology improvements.

Building on the success of its previous conferences, SulGas Mumbai 2025 brought together 154 sulphur and gas treating stakeholders, representing 68 companies for its 7th technical forum in the Indian subcontinent. We report on some of the key topics on the agenda.

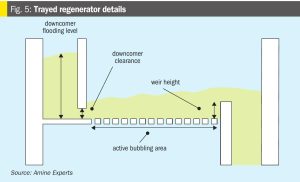

Preventing regenerator amine carryover to the sulphur recovery unit can have catastrophic consequences and must be avoided at all costs. B. Spooner and M. Sheilan of SGS Amine Experts detail how by correctly interpreting operating data, having proper instrumentation and good chemical analysis, amine carryover can be prevented.

NextChem (Maire) is awarded a three-year engineering and technology services contract by Satorp in Saudi Arabia to improve energy efficiency and carbon footprint

The 2030 greenhouse gas emission reduction goals in the European Union are driving oil and gas producers to reduce CO2 emissions wherever possible. This extends to even the incinerator attached to a sulphur recovery unit (SRU). In this article Sulphur Experts review the role of the incinerator, how the three most common European TGUs each affect the demand on the incinerator itself, and the potential reduction in CO2 emissions for a generic facility of each type.

A complete listing of all articles and news items that appeared in Sulphur magazine during 2024.

The development and implementation of modern process instruments and control systems in sulphur recovery units has increased significantly over the last decade. In this article, the impact of BTEX on sulphur plant operations and how the BTEX concentrations can be measured are discussed.