Canada’s sulphur exports

Though production, particularly from sour gas in Alberta, has declined, Canada remains the world’s second largest exporter of sulphur.

Though production, particularly from sour gas in Alberta, has declined, Canada remains the world’s second largest exporter of sulphur.

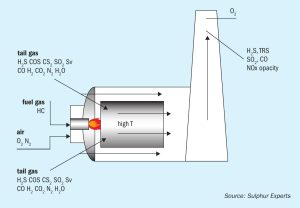

The Aecometric 3rd generation burner was developed, installed and commissioned for an SRU incinerator with increased stringent demands to reduce NOx emission and lower energy consumption. Mason Lee of Aecometric Corporation reports on the new burner design and performance. The emission test results show a significant improvement in addressing these environmental concerns to achieve low NOx (<50 mg/m3 ) combustion and minimise CO (<200 mg/m3 ) emissions.

Sulphur Experts outline the steps required to determine optimised SRU incinerator operating conditions. Although a proper determination of the ideal SRU incinerator operating conditions for any given facility is complicated by a combination of inconsistent permitting standards and poor understanding of the role of the SRU incinerator, the payoff for incinerator optimisation is a significant decrease in natural gas usage with corresponding savings in operating costs, a decrease in CO2 emissions, and a simultaneous reduction in NOx and SO3 emissions.

CRU and UniverSUL Consulting, together with the event host, ADNOC, are delighted to welcome you back for MEScon 2024 at the Conrad Abu Dhabi, Etihad Towers from 20 to 23 May 2024.

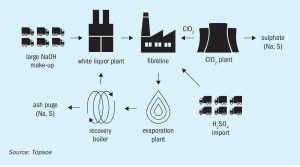

The implementation of WSA technology to recover sulphur as sulphuric acid from lean sulphurous off-gases offers significant environmental benefits. These include waste reduction, resource efficiency and reduced overall CO2 e footprint, while also producing profitable sulphuric acid. By embracing such practices, industries can ensure improved or better consumption and production patterns and foster a more sustainable and responsible future. J. Feddersen and S. S. Johansson of Topsoe illustrate these benefits using three distinct industrial applications where WSA technology provides a smarter way to treat sulphurous off-gases. It is not only waste stream management in the three cases, but also reduced transportation of chemicals, reduced opex and reduced CO2 e footprint.

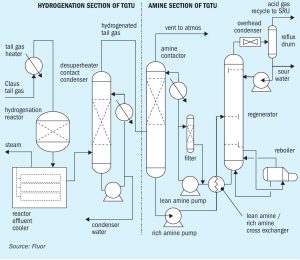

As environmental SO2 emission regulations become more stringent, tail gas treating options become limited. To potentially achieve lower opex and improved plot plan, utilising a biological desulphurisation process as an alternative to a conventional amine-based TGT unit is becoming of increased interest in the oil and gas industry. At the same time, demands for increased SRU capacity and reliability favour the use of medium and high-level oxygen enrichment.

More than 155 attendees, representing more than 68 companies gathered in Mumbai, India, from January 31 to February 2, 2024 for the annual SulGas® conference, organised by Three Ten Initiative Technologies LLP. We report on the key highlights of the event.

Already the world’s largest exporter of sulphur, Abu Dhabi continues to expand its sour gas production and sulphur output.

Small quantities of sulphur in a refinery or gas feed can present challenges for conventional large scale sulphur recovery techniques.

Axens has developed a new titania-based catalyst named CRS 41, which has a much larger porosity than its renowned predecessor, CRS 31 catalyst. Thanks to an improved catalyst manufacturing process and a new recipe, the porosity of CRS 41 has been increased while preserving the mechanical resistance for loading, allowing customers to optimise their capex by either reducing the Claus reactor size or loading volume of TiO2 catalyst.