Sulphur + Sulphuric Acid 2023

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.

Tecnimont, part of MAIRE’s Integrated E&C Solutions business unit, has signed a letter of award with ADNOC for the onshore processing plant of the Hail and Ghasha Development Project. The award was signed at ADIPEC, the world’s largest energy summit. The project aims to operate with net zero CO 2 emissions, in part due to the facility’s CO 2 carbon capture and recovery units, which will allow the capture and storage of CO 2 . The project will capture 1.5 million t/a of CO 2 , taking ADNOC’s committed carbon capture capacity to almost 4 million t/a. The company recently announced its decision to double its carbon capture capacity to 10 million t/a by 2030. The Hail and Ghasha CO 2 will be captured, transported onshore and stored underground, while low-carbon hydrogen will be produced to replace fuel gas and further reduce emissions, according to ADNOC. The project will also use power from nuclear power plants and renewable sources from the grid.

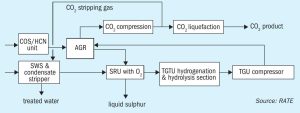

RATE USA discusess some of the many solutions available to revamp sulphur plants to meet stricter environmental regulations with regard to SO2 and CO2 emissions.

Following the completion of expansion work on the ultra-sour gas Shah field in May 2023, production has been ramped up. Occidental, which owns 40% of the Shah project and which operates the field in conjunction with ADONC Sour Gas, reported in July that it had achieved record output at Shah, with gross gas sales reaching 722 million scfd in Q2 2023 (equivalent to 1.1 billion scf/d of raw gas, which is 23% H2S and 10% CO 2 ). The expansion has taken processing capacity at Shah to 1.45 billion scf/d and forms part of the UAE’s plans to achieve gas self-sufficiency by the end of the decade. The expansion was conducted by Saipem, who were awarded a $510 million contract in 2021 to expand output from 1.3 billion scf/d to the current 1.45 billion scf/d. Work was completed two months ahead of schedule, according to Occidental.

With the aid of a rigorous kinetic model for TGU hydrogenation reactors, incorporating catalyst deactivation mechanisms, designers and operators can forecast the life expectancy of reactor catalyst beds.

Comprimo and Ametek now offer the Analyser Air Control Technology (2ACT) Solution to the industry which enables operating companies to control their assets closer to design capacity at higher recovery efficiency and with fewer unscheduled outages.

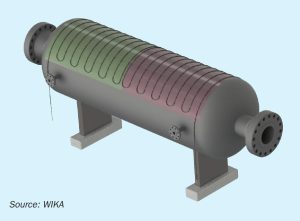

WIKA discusses a novel and easy way to monitor the shell temperature of the Claus thermal reactor using proven technology and highlights the benefits a purge-less thermocouple system for high temperature measurement.

This June marks a milestone for this magazine; a platinum jubilee since the very first issue of the magazine was printed in 1953. It began life as the Quarterly Bulletin of the Sulphur Exploration Syndicate. The Syndicate was created in 1952, and was backed by nine major chemical producers, mainly in Britain and the US, who were concerned about dwindling world supplies of sulphur. Though some of these companies have vanished by the wayside over the years, including F.W. Berk and Co. Ltd, British Titan Products, Brotherton & Co., and Charles Tenant & Sons Ltd, others remain household names to this day, including Monsanto, Courtaulds (now part of Akzo-Nobel), and Dunlop (now owned by Goodyear), while Fisons’ fertilizer division was sold to Norsk Hydro in 1982 and today trades as part of Yara.

There is a growing skills gap in the sulphur industry due to the changing nature of the workforce. The traditional ways of doing things are no longer working effectively. Knowledge is lost with retiring subject matter experts (SMEs) and other experienced operations staff leaving a reducing pool of SMEs. In this article a case study reviews how knowledge automation solved the skills gap in a sulphur recovery unit at a major US refinery.

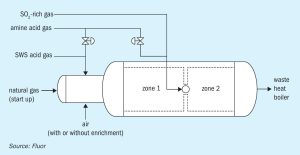

Fluor investigates how SO2 impacts the Claus furnace temperature in an SRU and the ways to mitigate it. This article studies the extent of quenching experienced in the Claus furnace with varying amounts of SO2 in the Claus feed. A case study is presented based on real operating data of a refinery Claus plant with a feed gas cocktail that includes substantial SO2 recovered from a regenerative flue gas desulphurisation unit.