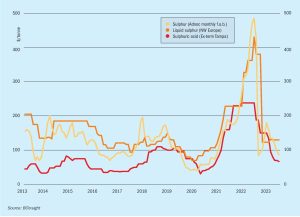

Market Outlook

Indonesian imports have increased in 2023 so far on a year earlier. As new nickel high pressure acid leach projects ramp up, demand for sulphur is expected to increase further. Swing buyers have been importing significant volumes of sulphuric acid, affecting short term sulphur demand in the second quarter. It remains to be seen if this will continue, we expect sulphur demand to ramp up further in the second half of the year, bringing import expectations for the year to around 2 million t.