Developments in phosphate markets

Tight supply limits availability as China maintains export restrictions.

Tight supply limits availability as China maintains export restrictions.

Philippine Associated Smelting and Refining (PASAR) has put its plant on Leyte Island into care and maintenance to evaluate the operation amid what it termed as increasingly challenging market conditions.

Yara says that it plans to wind down production of phosphate fertilizers and sulphuric acid at two sites in Brazil; Cubatão and Paulínia. The sites are expected to cease production by 3Q 2025, as part of what Yara describes as a strategy to concentrate on more sustainable operations focused on its main activity: the production of nitrogen fertilizers. At Cubatão, the suspension will affect unit 3 and the phosphate plants of unit 2, while units 1 and 2, responsible for the production of nitrogen, in addition to the mixer (unit 5), will continue to operate normally. Yara reported a net loss of $290 million in 4Q 2024, down $536 million from the $246 million profit it made in 4Q 2023. Revenues are down 11% for the year, leading Yara to announce a cost reduction and investment program of $150 million, with the aim of optimising its operations and focusing on strategic areas to ensure long-term sustainability. At the same time, the company has begun renewable ammonia production at Cubatão.

The Chinese government has issued a development plan for the country’s copper smelting industry covering the years 202527 which is looking to reduce the level of overcapacity in the sector. New copper smelters must now control sufficient copper mine supply via ownership or equity stakes to cover their production requirements, something few smelters do at present. Chinese smelter output has reached record levels, with treatment charges falling to historically low levels as producers compete for copper concentrate – China imports around 85% of its copper concentrate. Meanwhile more smelter capacity is planned, with around 1 million t/a of new capacity scheduled for 2025. The country aims to boost domestic copper mine resources by 5% to 10% in three years to secure raw material supply, according to the government plan. China will also encourage copper smelters to sign long-term purchase agreements with global miners, boost imports of copper blister and anode, and encourage scrap imports.

Metso has launched its new Cu POX leaching process for the copper extraction industry. The company says that, as ore compositions change due to depletion of deposits and increasing environmental and efficiency demands, this solution not only maximises copper recovery but also reduces environmental impact.

Nickel Asia Corp. (NAC) says that it has completed the sale of its 15.6% stake in Coral Bay Nickel Corp. to its Japanese partner Sumitomo Metal Mining. Nickel Asia says that the sale has been due to “unfavourable market conditions” for the high pressure acid leach (HPAL) nickel processing plant. Although Coral Bay is regarded as one of the most efficient HPAL units in the world, nickel prices have been extremely volatile over the past few years and stood a 4-year lows in January at around 15,000/t, their lowest level since September 2020. Nickel Asia still owns a 10% stake in the Taganito HPAL Nickel Corp.

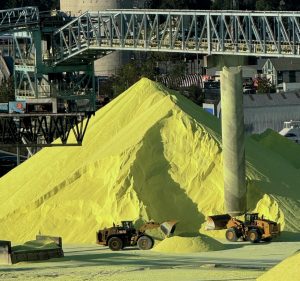

Global sulphur benchmarks rallied at the end of February, underpinned by strong demand in Indonesia and stock drawdowns in China as fresh European sanctions on Russia targeted the port of Ust-Luga. Chinese buyers paid up to $225t/t c.fr for a cargo, with unconfirmed rumours of business at even higher levels. However, delivered prices still lag domestic port spot prices in China, which are now assessed at a delivered-price equivalent of around $242/t c.fr. China’s delivered sulphur price jumped significantly as port inventories declined, and new arrivals were limited. Only two new cargoes were reported in the last week of February, one from a mainstream source into southern China at $205/t c.fr, and the second at $225/t c.fr by a phosphate producer for the Yangtze River. The sulphur port spot transaction price is reported at around 2,0402,050 yuan/t FCA ($281-283/t), with the low-end up $26/t and high-end up $25/t compared with previous settlements. That port price indicates delivered values at around $242/t c.fr, which is $17/t higher than the import price on the Yangtze. Phosphate producers need to purchase more sulphur to meet the increased buying activity in northeastern market and the improving spring application season demand in northern China. Still, market sales availability is limited, as most port tonnes are held by traders instead of end-users, while traders are selling limited quantities now to push prices higher. Chinese total port inventory dropped to 1.89 million tonnes by 26 February 2025. The quantity at Yangtze river ports declined 59,000 tonnes to 633,000 tonnes, while Dafeng port inventory decreased 20,000 tonnes to 450,000 tonnes.

Rapidly increasing lithium production is projected to require several million t/a of sulphuric acid in the next few years, with China, the USA and Australia the main consumers.

The first installed combination of a regenerative SO2 scrubbing system with a sulphuric acid plant using Worley Chemetics’ CORE™ reactor technology started up in November 2022. The combination of these technologies allows production of high-grade sulphuric acid from gases with low and/or fluctuating SO2 concentrations. C. Trujillo Sanchez and R. Dijkstra of Worley Chemetics report on the design concepts of this integrated process, highlight where it is most effective and report on the start-up and first years of operation of the plant.

Apart from having a good plant design, good maintenance practices and good operational discipline are key to optimise the performance of an acid plant and to protect it from corrosion and achieve a long life. B. Mumba, T. Mwanza and P. Ng’ambi of Kansanshi Mining PLC explore the Kansanshi sulphuric acid plant operations and the key parameters monitored and practices adopted that have helped to extend the catalyst campaigns from two years to four years.