Sulphuric Acid News Roundup

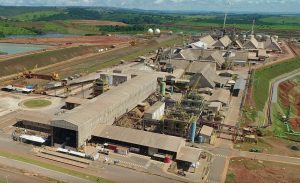

INEOS Enterprises has announced the completion of the sale of its Sulphur Chemicals business to International Chemical Investors Group, for an undisclosed sum. INEOS Sulphur Chemicals business is Spain’s largest dedicated manufacturer of sulphuric acid and oleum, serving clients in both agriculture and chemical intermediates via its 400,000 t/a plant in Bilbao. The business will become part of WeylChem’s advanced intermediates and reagents portfolio, which includes an existing sulphuric acid and oleum plant located in Lamotte, northern France. WeylChem is wholly owned by the International Chemical Investors Group (ICIG).