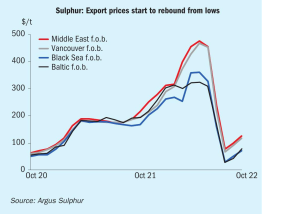

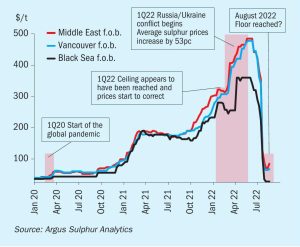

Price Trends

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Global demand for rare earth metals is increasing, particularly for electric vehicle batteries and renewable energy devices, potentially leading to increased use of sulphuric acid in their extraction.

The Broadfield process has remained a mainstay of the global phosphate industry since its introduction in the 1930s. Ian Hancock, vice president sales & operations, Bradley Pulverizer, explains it continuing success in superphosphate production worldwide

Saudi Arabia’s Ras Al-Khair Industrial City has signed an industrial land agreement with local firm Gulf Copper to develop a copper smelting and casting plant at an investment $319.30 million. The project would be developed on a plot spanning more than 250,000 square metres in the industrial city. No construction timelines were given. The Saudi government has previously signed agreements with Trafigura and Saudi-based Modern Mineral Holding to develop a 400,000 t/a copper smelter at Ras Al Khair which would also include 200,000 t/a of zinc and 55,000 t/a of lead smelter capacity at a projected cost of $2.8 billion.

While most sulphuric acid demand for phosphates is based on the production of phosphate fertilizer, non-fertilizer sources of demand such as animal feed and industrial processes additionally represent a relatively small but growing sector of the market.

Reduced appetite for sulphur from processed phosphates producers in China will continue to place downwards pressure on pricing in the near term. l Phosphates-based demand is likely to remain low in the second half of 2022 as issues surrounding affordability persist, slowing import requirements.

The US refining sector continues to face operating pressures with 1.3 million bbl/d of closures in the past three years, while sour gas sulphur production has recovered somewhat. Meanwhile, demand from copper and lithium leaching projects will increase use of sulphuric acid over the next few years.

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

After two years of virtual events, the CRU Sulphur + Sulphuric Acid 2022 Conference & Exhibition will return to an in-person event at the World Forum, The Hague, 24-26 October 2022. CRU will be welcoming the global sulphur and sulphuric acid community to this premier annual event for networking and essential updates on the markets and technical developments that are influencing the industry.

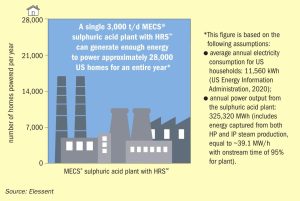

By recovering waste heat as process steam or electrical energy, technologies are available that can help sulphuric acid plants meet their energy goals. Colin Shore of Elessent Clean Technologies discusses how MECS® HRS™ technology can offer a sustainable solution to enhance sulphuric acid plant performance, while lowering its carbon emissions.