Abu Dhabi’s sour gas expansions

Already the world’s largest exporter of sulphur, Abu Dhabi continues to expand its sour gas production and sulphur output.

Already the world’s largest exporter of sulphur, Abu Dhabi continues to expand its sour gas production and sulphur output.

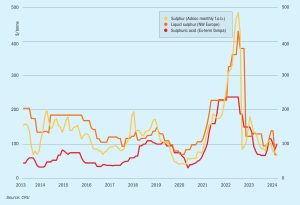

CRU expects sulphur prices to be supressed in early 2024 by high port inventory and limited phosphate export business. However, affordability continues to support raw materials purchases and leaves room for price increases, especially if downstream production picks up as expected and sulphur stock drawdown slows.

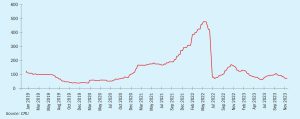

Urea. As February ended, urea prices found support in the US and Brazil while Europe remained subdued and Egypt struggled to find buyers. New Orleans was the one bright spot in the urea market – with NOLA prices benefitting from the meeting of suppliers and buyers at the TFI’s domestic conference. With positive sentiment all round, prices moved up $30/st, peaking at $390/st f.o.b. for March.

Pyrite roasting as a source of sulphuric acid continues to be a significant, albeit minor sector of the overall acid market.

US domestic oil production has surged during 2023, reaching 13.3 million bbl/d in December, a record not just for the US but for any single country’s oil production. Adding in natural gas liquids and biofuels takes overall liquids production to 21.4 million bbl/d. Exports are also running at record levels, around 6 million bbl/d. This is a remarkable turnaround from 2008, when production was less then 5 million bbl/d and exports essentially zero. Furthermore, non-OPEC production is continuing to expand, with Brazil reaching 3.4 million bbl/d of oil production and 4.2 million bbl/d of liquids, and Canada producing 4.8 million bbl/d of crude and 5.7 million bbl/d of total liquids, keeping oil prices moderated in spite of OPEC+ production cuts. Global oil production is expected to reach a record level in 2024, with non-OPEC+ liquids growth projected to increase by 2.7 million bbl/d, far more than demand growth of 1.6 million bbl/d. n

Small quantities of sulphur in a refinery or gas feed can present challenges for conventional large scale sulphur recovery techniques.

Sulphur prices declined in Q4 following the increases seen during Q3, because of ample availability and limited spot demand. One contributing factor was that phosphate fertilizer producers in China, the largest importer of sulphur, have cut downstream production due to increased export restrictions. In addition, high sulphur stocks at Chinese ports and continuing high domestic sulphur production mean that domestic buyers have other options aside from international purchases.

Sulphur prices are expected to increase during H1 2024, reversing the trend of recent declines, though good availability will limit the upside to price gains in the short term. However, should fertilizer production prove weaker than expected, prices may remain below expected levels.

We are very pleased to be able to tell you that, as of this issue, Nitrogen+Syngas magazine has a new publisher. Or rather, an old publisher, as the magazine is now once again part of the CRU Group.

Urea: December began on a positive note with a flurry of Egyptian urea sales and firmer prices for delivery to Brazil. The increase in values was short lived, however, and piecemeal demand in Europe was insufficient to halt the downward trend. By mid-December, buying interest from Brazil had fizzled out, although sellers breathed a sigh of relief when India’s NFL floated a new import tender on 21st December.